A kind of preparation method of multi-component composite rare earth oxide with high conductivity layered structure

A rare earth oxide and multi-component composite technology, which is applied in the preparation of molybdenum compounds, chemical instruments and methods, molybdenum compounds, etc. Large-scale production, simple reaction synthesis conditions, and the effect of improving electrical and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

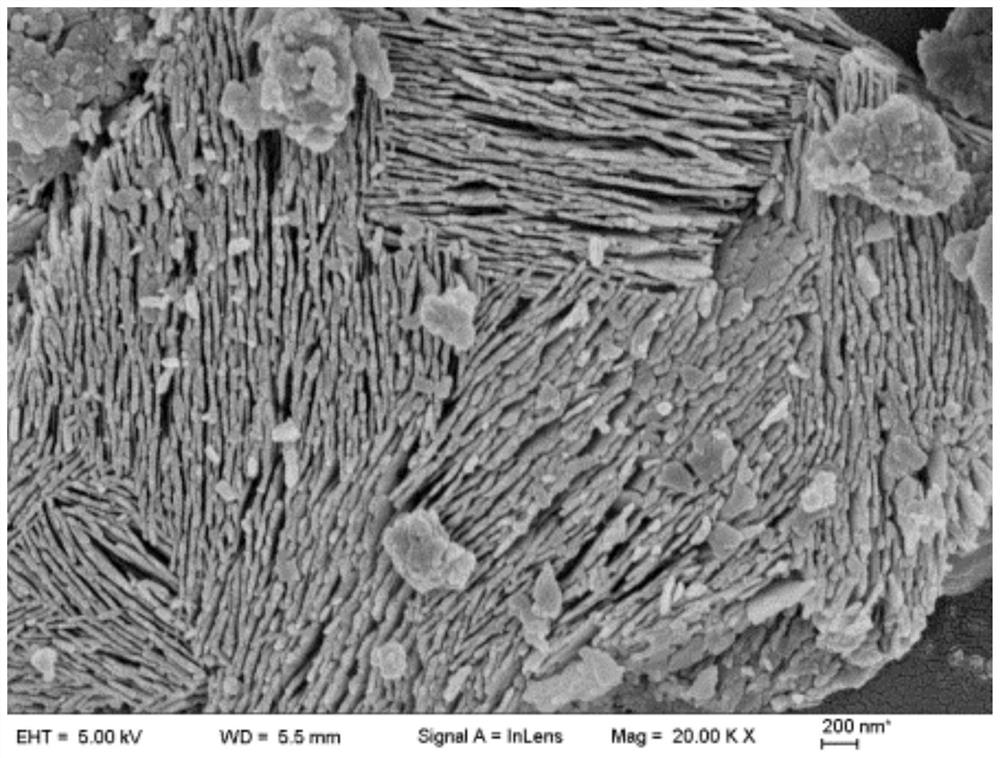

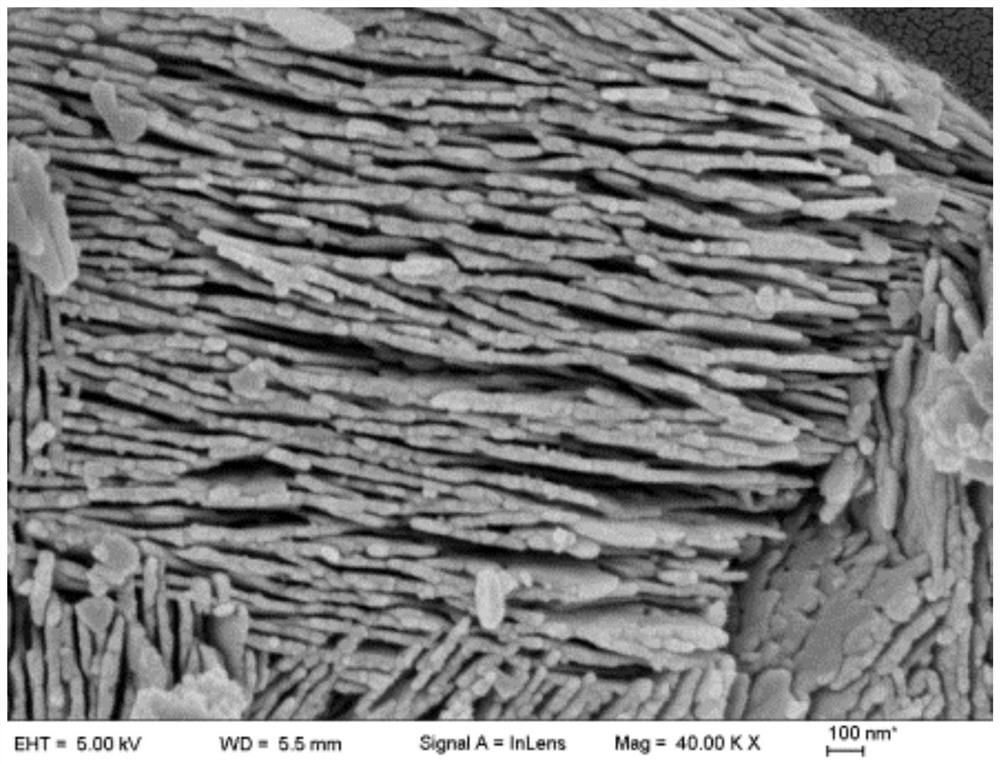

Image

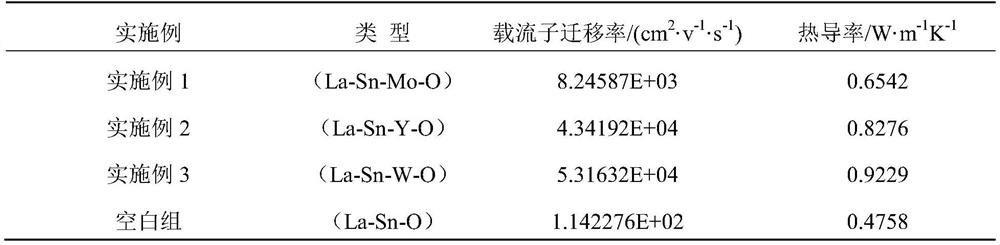

Examples

Embodiment 1

[0028] (1) Preparation of precursor solution A

[0029] The solute is citric acid and structure inducer Na in molar ratio = 1.5:1.5 2 MoO 4 , the solvent is to add a certain amount of propylene oxide gel accelerator (the mixed solution of mol ratio=0.5:1 between propylene oxide and citric acid; a certain amount of solute is added in the solvent, stirred until completely dissolved with magnetic force, and then Use a glass rod to transfer the liquid to a volumetric flask to constant volume, and prepare a colorless and transparent solution with a concentration of 0.03 mol / L, which is designated as precursor solution A.

[0030] (2) Preparation of precursor solution B

[0031] The solute is lanthanum nitrate and tin tetrachloride pentahydrate with a molar ratio of 1:1, and the solvent is deionized water; the solute is introduced into deionized water, stirred with magnetic force until completely dissolved, and then pipetted into a volumetric flask with a glass rod to stabilize T...

Embodiment 2

[0036] (1) Preparation of precursor solution A

[0037] The solute is citric acid and structure inducer Y (NO 3 ) 3 ·6H 2 0, the solvent is to add a certain amount of propylene oxide gel accelerator (the mixed solution of mol ratio=2.5:1 between propylene oxide and citric acid; a certain amount of solute is added in the solvent, until completely dissolved with magnetic stirring, Then use a glass rod to transfer the liquid to a volumetric flask to constant volume, and prepare a colorless and transparent solution with a concentration of 0.03 mol / L, which is designated as precursor solution A.

[0038] (2) Preparation of precursor solution B

[0039] The solute is lanthanum nitrate and tin tetrachloride pentahydrate with a molar ratio of 1:1, and the solvent is deionized water; the solute is introduced into deionized water, stirred with magnetic force until completely dissolved, and then pipetted into a volumetric flask with a glass rod to stabilize To prepare a colorless and...

Embodiment 3

[0044] (1) Preparation of precursor solution A

[0045] The solute is citric acid and structure inducer Na in molar ratio = 1.5:0.8 2 WO 4 2H 2 0, the solvent is to add a certain amount of propylene oxide gel accelerator (the mixed solution of mol ratio=1.2:1 between propylene oxide and citric acid; a certain amount of solute is added in the solvent, until completely dissolved with magnetic stirring, Then use a glass rod to transfer the liquid to a volumetric flask to constant volume, and prepare a colorless and transparent solution with a concentration of 0.03 mol / L, which is designated as precursor solution A.

[0046] (2) Preparation of precursor solution B

[0047] The solute is lanthanum nitrate and tin tetrachloride pentahydrate with a molar ratio of 1:1, and the solvent is deionized water; the solute is introduced into deionized water, stirred with magnetic force until completely dissolved, and then pipetted into a volumetric flask with a glass rod to stabilize To p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com