Workpiece distributing system based on image recognition

A technology for image recognition and workpieces, applied in sorting, conveyor objects, conveyor control devices, etc., can solve the problems of reduced production efficiency, improve processing efficiency, avoid long-term no-load operation, and save system energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

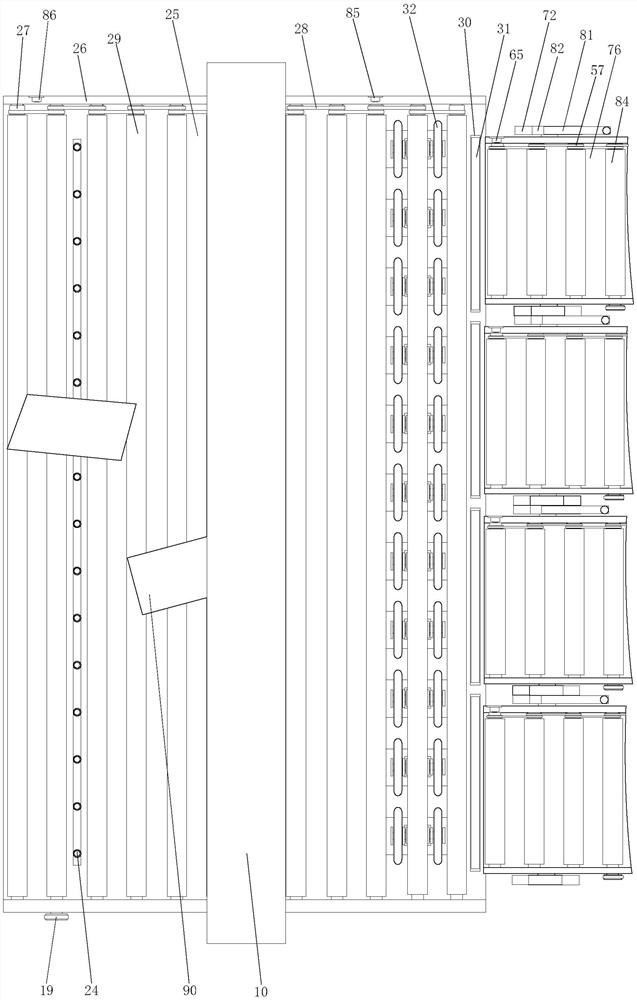

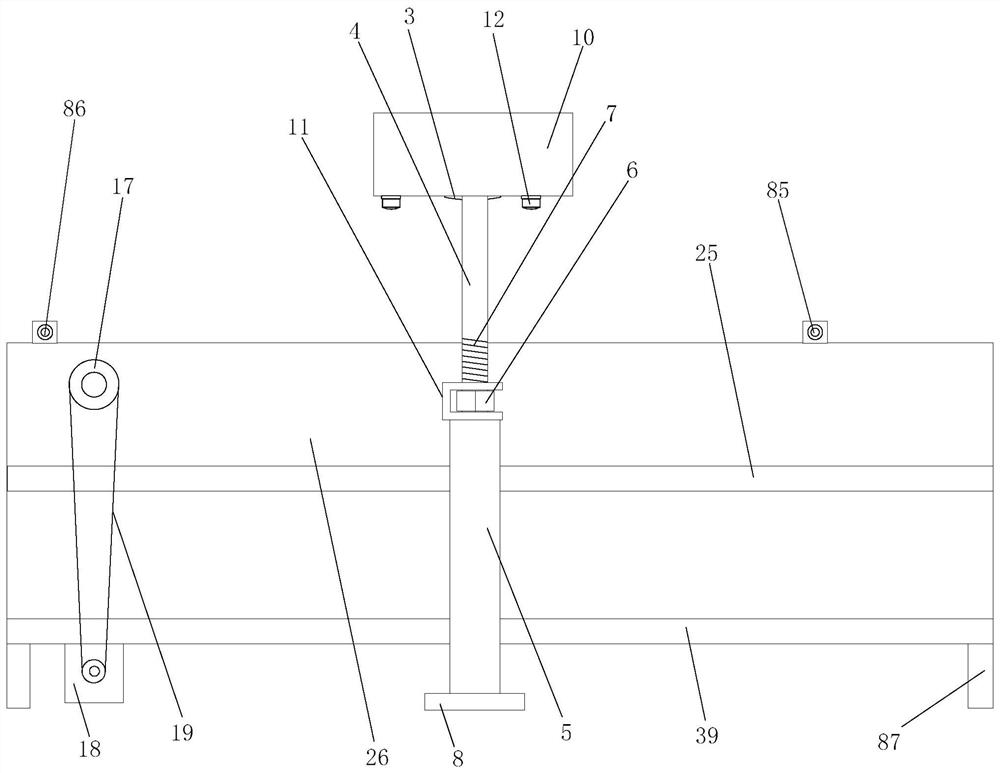

[0026] Such as Figure 1-6 As shown, the workpiece distribution system based on image recognition disclosed in the present invention includes: a transfer conveying roller bed, an image recognition mechanism, a lateral transfer mechanism, a blocking and limiting mechanism, and each branch conveying roller bed;

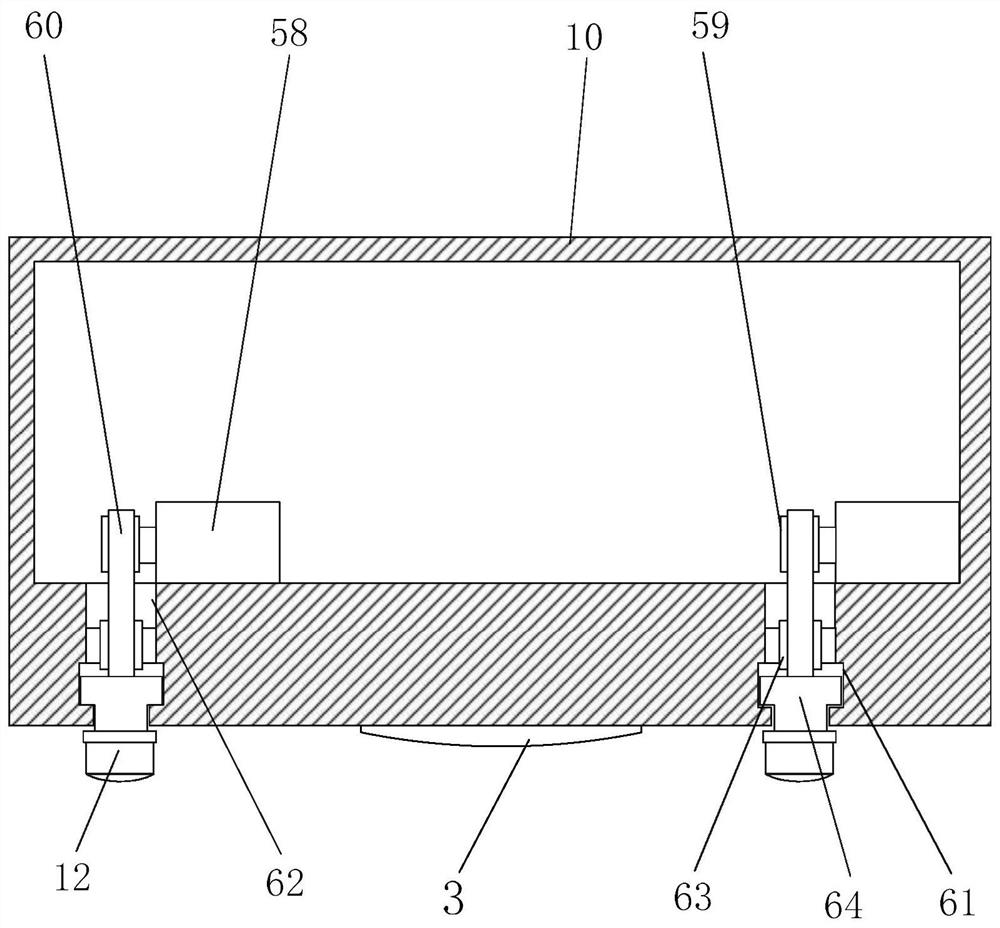

[0027] The image recognition mechanism includes a control box 10, a recognition installation bracket and an image recognition camera 12; the control box 10 is installed above the transfer roller bed through the identification installation bracket; a controller, a WiFi module and a memory are installed in the control box 10 ; The image recognition camera 12 is installed on the lower side of the control box 10;

[0028] The transverse transfer mechanism is installed on the unloading side of the transfer roller bed, and is used for laterally conveying the workpiece 90 on the unloading side; For the workpiece 90 corresponding to the docking transportation; the blocking lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com