Cleaning device for medical equipment

A technology for cleaning devices and medical devices, which is applied to cleaning methods using liquids, dry gas arrangements, chemical instruments and methods, etc., and can solve problems such as poor cleaning efficiency, inability to rinse medical devices, and small contact area between medical devices and cleaning devices. , to reduce the effect of cleaning dead corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

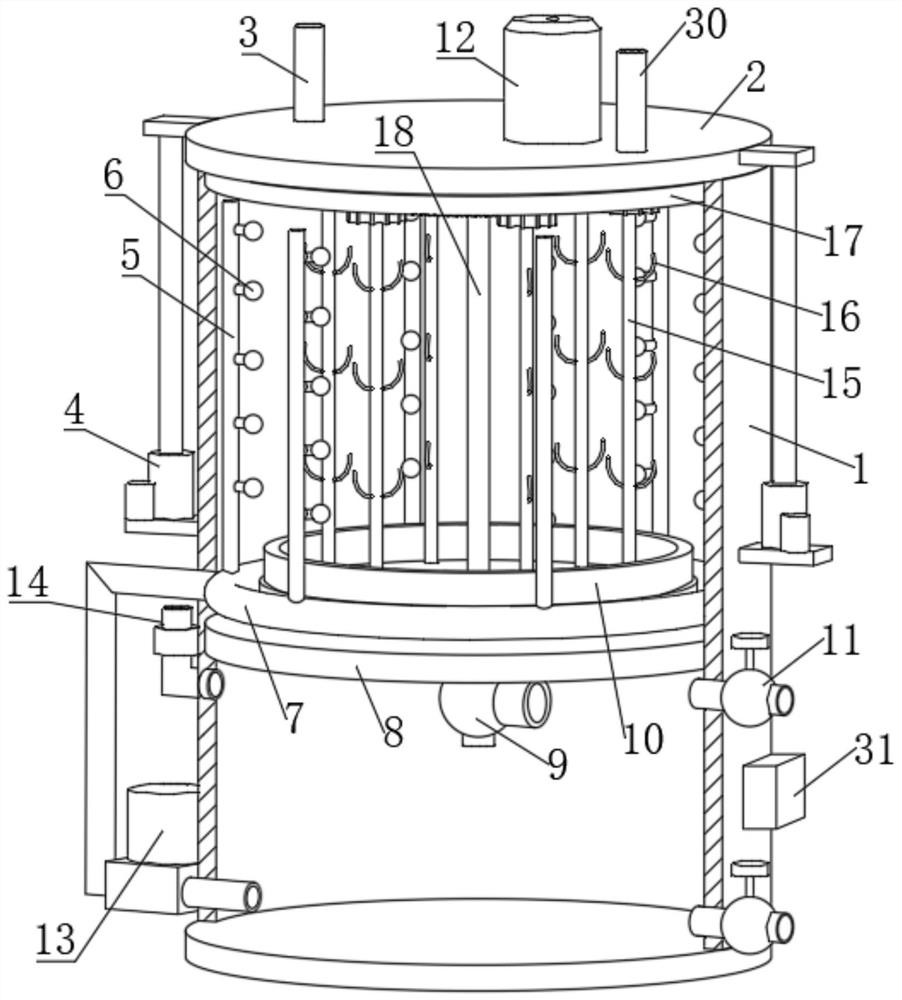

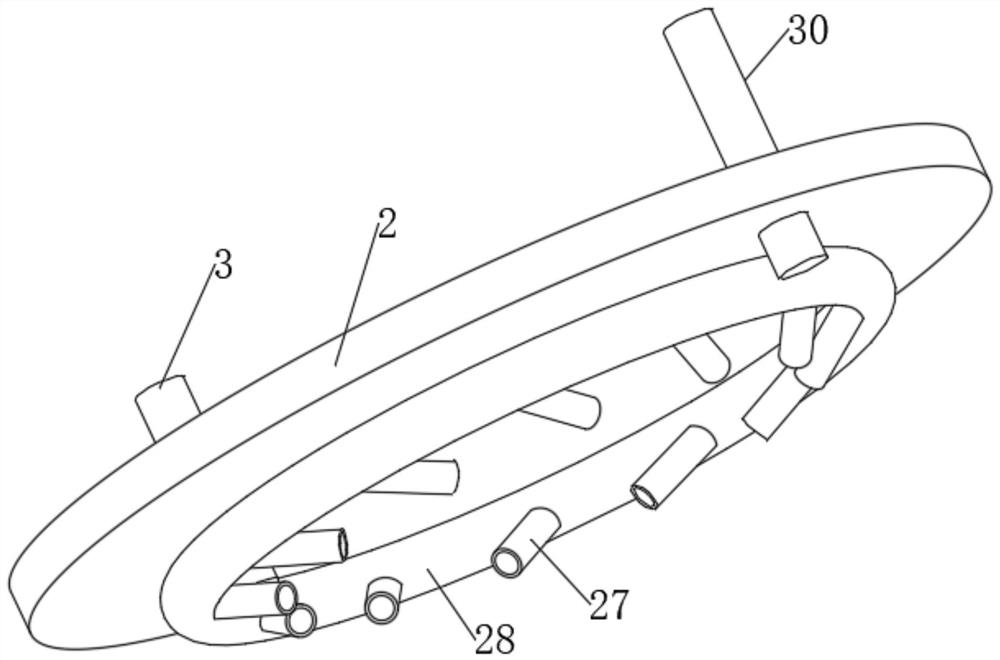

[0026] A cleaning device for medical instruments, comprising a tank body 1, an electromagnetic water valve 9 and a PLC controller 31 fixed on the tank body 1, the upper end of the tank body 1 is provided with an opening, and a cover plate 2 is provided at the edge of the opening, and the cover plate There are two connecting plates symmetrically fixedly connected to the edge of the plate 2, and the lower ends of the two connecting plates are fixedly connected with the electric push rod 4, and the end of the electric push rod 4 away from the connecting plate is fixedly connected with the side wall of the tank body 1, and the cover plate The lower end of 2 is fixedly connected with a circular ring 17, the edge of the circular ring 17 is slidingly connected with the inner edge of the upper opening of the tank body 1, and the inner side of the circular ring 17 is fixedly connected with a connecting rod 19 horizontally, and the center of the rod wall of the connecting rod 19 A rotati...

Embodiment 2

[0028] Embodiment 2: the difference based on Embodiment 1 is;

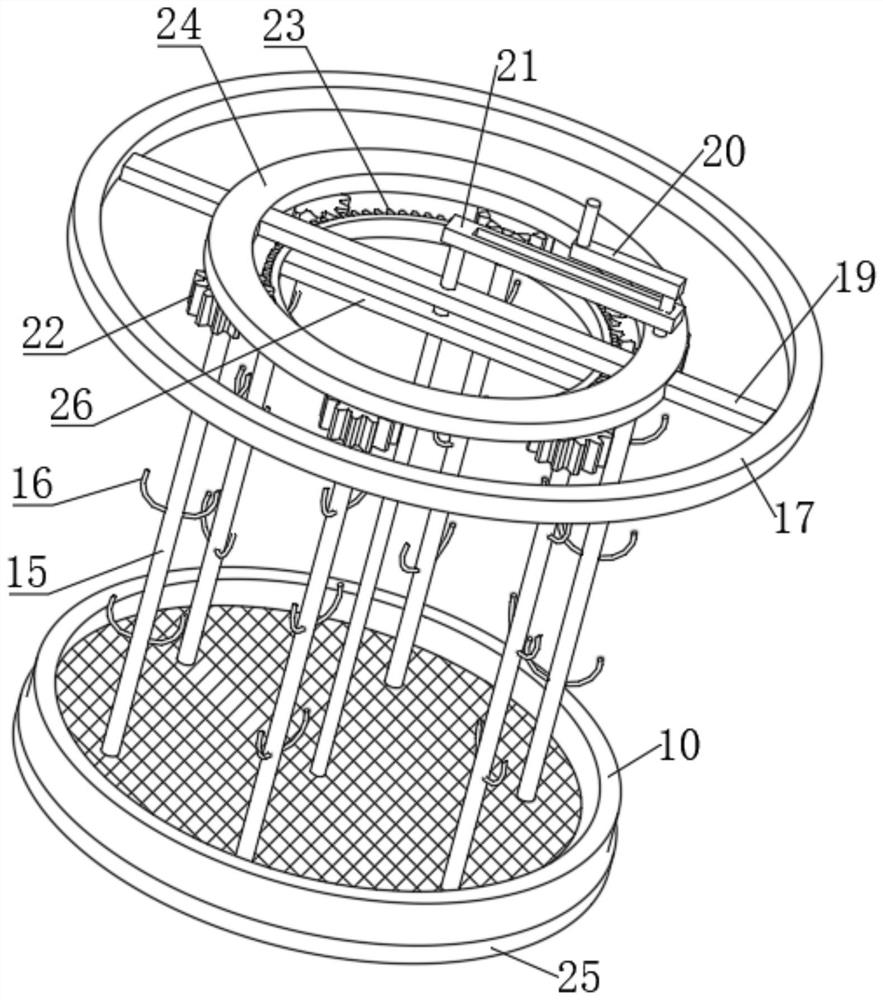

[0029] The transmission mechanism includes a ring gear 23 that is slidably sleeved on the shaft wall of the rotating shaft 18. The inner side of the ring gear 23 is fixedly connected with a fixed rod 26, and the center of the rod wall of the fixed rod 26 is fixedly connected with the shaft wall of the rotating shaft 18 through a circular opening. The rod wall of the rod 19 is fixedly connected with a positioning ring 24, and the lower end of the positioning ring 24 is vertically rotatably connected with a plurality of evenly distributed support rods 15, and the rod walls of the plurality of support rods 15 are fixedly connected with a gear 22. The gear 22 meshes with the ring gear 23, the rod wall of the support rod 15 is fixedly connected with a plurality of evenly distributed hooks 16, the upper end of the rotating shaft 18 is fixedly connected with a rectangular frame 21, and the rectangular frame 21 is slidably...

Embodiment 3

[0031] Embodiment 3: the difference based on embodiment 1 is;

[0032] The flushing mechanism includes a plurality of conduits 5 vertically fixed on the wall of the annular pipe 7, the plurality of conduits 5 are distributed in an annular array, and the pipe wall of the conduit 5 is fixedly connected with a plurality of evenly distributed water spray heads 6, and the tank body 1 A booster pump 13 is fixedly connected to the lower side of the left end of the booster pump, the input end of the booster pump 13 is fixedly connected to a connecting pipe, one end of the connecting pipe is fixedly connected to the side wall of the tank body 1, and the output end of the booster pump 13 is fixedly connected to a delivery One end of the conveying pipe runs through the side wall of the tank body 1 and is fixedly connected with the pipe wall of the annular pipe 7. The left end of the tank body 1 is fixedly connected with a ventilation pipe 14, and the center of the upper end of the partiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com