Composite nutritional oak vermicelli and preparation method thereof

A technology of oak oak and vermicelli, applied in the field of compound nutritional oak vermicelli and its preparation, can solve the problems of insufficient nutrition and single ingredients, and achieve the effects of rich nutrition, disease prevention and sleep improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

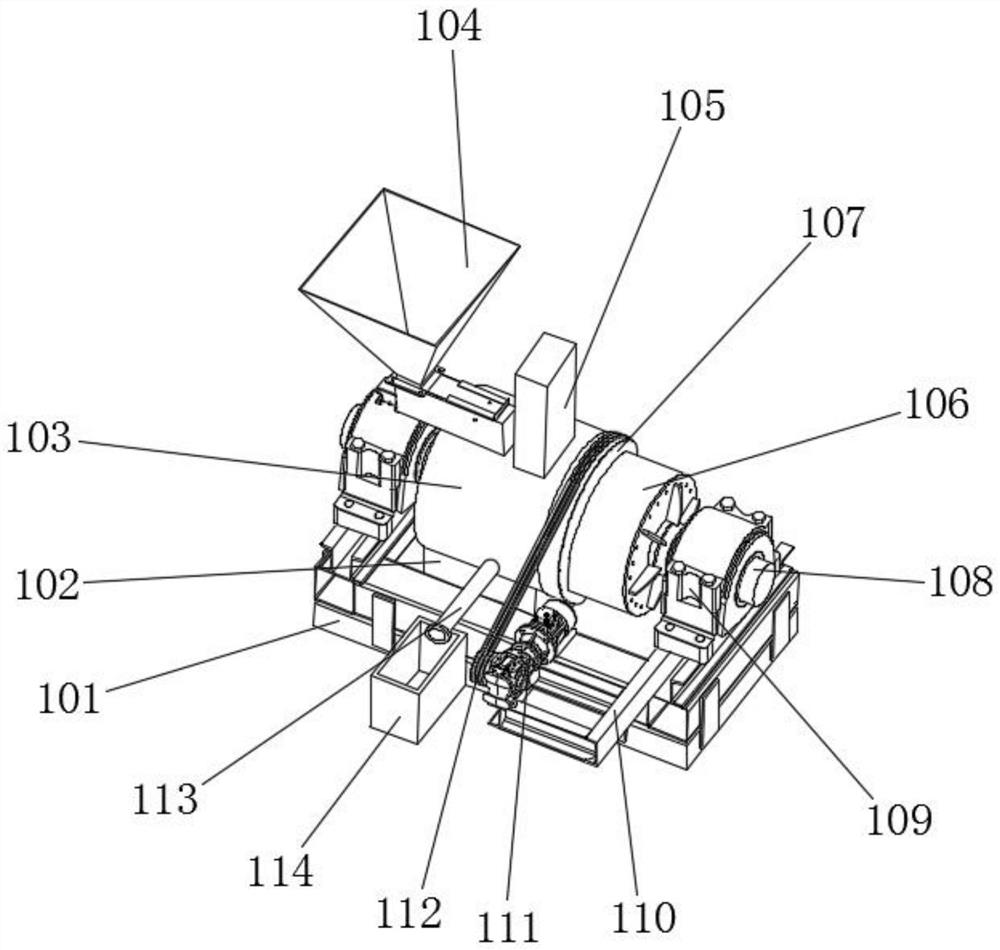

[0047] see Figure 1-5 Shown, the present embodiment is compound nutrient oak vermicelli, comprises following components by weight:

[0048] 100 parts of oak starch, 20 parts of Moringa leaf powder, 8 parts of tomato pulp, 0.03 parts of salt;

[0049] The compound nutrition oak vermicelli is prepared by the following steps:

[0050] Step 1: Select fresh oak oaks, shell them and wash them with a sieve, and set aside;

[0051] Step 2: Add 0.04 parts by weight of citric acid to 100 parts by weight of clear water, then add the fresh oak oak after shelling and sieving to clean water containing citric acid for immersion for 36 hours, and control the temperature at 45 ° C. Change the water once every 5 hours, dehydrate the fresh oak after soaking, put it into a vibrating sieve to remove impurities, crush it to 20 mesh, and then add the crushed fresh oak to the hopper 120 of the refining equipment, Fill the water tank 105 with clear water, start the drive motor 111, the drive motor...

Embodiment 2

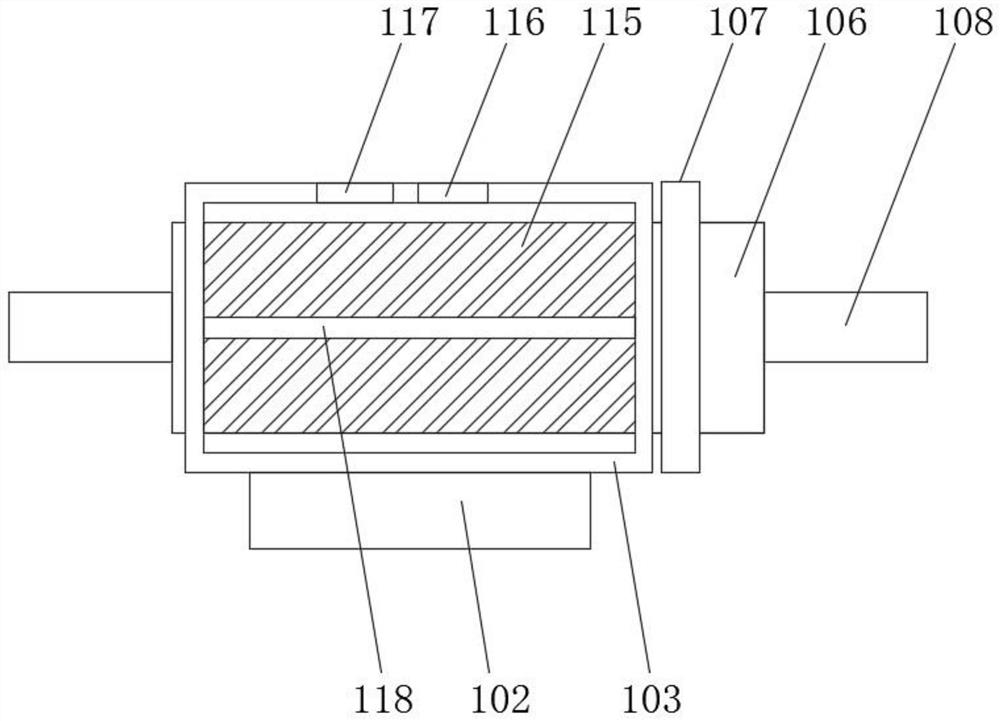

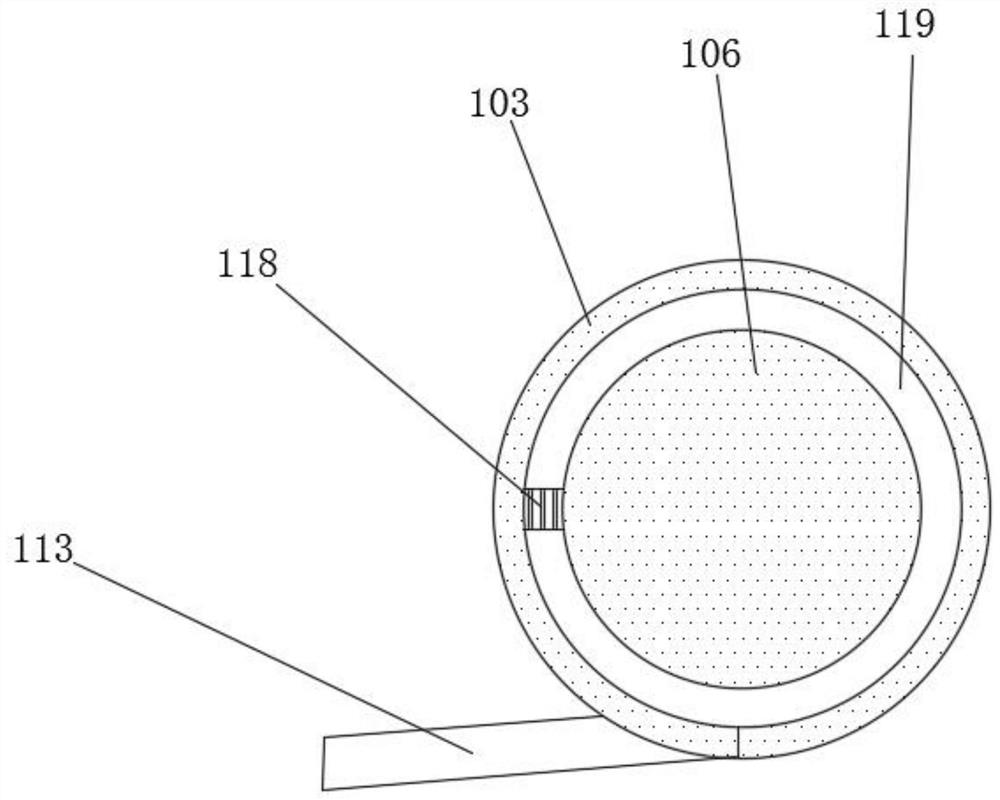

[0061] see Figure 1-5 As shown, the refining equipment in this embodiment includes a support base frame 101, a support seat 102, a grinding cylinder 103, a feeding mechanism 104, a water storage tank 105, a grinding body 106, a transmission belt ring 107, a linkage shaft 108, and a bearing seat 109. Mounting frame 110, drive motor 111, transmission pulley 112, discharge pipe 113, material receiving box 114, the support base 101 is a rectangular frame, and the inner cavity of the support base 101 is provided with a support seat 102, A grinding cylinder 103 is installed on the top of the support base 102, and the grinding cylinder 103 is sleeved on one end of the grinding body 106. Both linkage shafts 108 are installed, and the two linkage shafts 108 are sleeved with bearing seats 109, and the two bearing seats 109 are respectively installed on the two ends of the top of the support chassis 101, and the top of the grinding cylinder 103 One end is equipped with a water storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com