Electronic component gluing device

A technology of electronic components and glue covering, which is applied in the direction of electrical components, printed circuits, printed circuit manufacturing, etc., can solve the problems of raw material waste, staff contamination with glue, and glue solidification, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

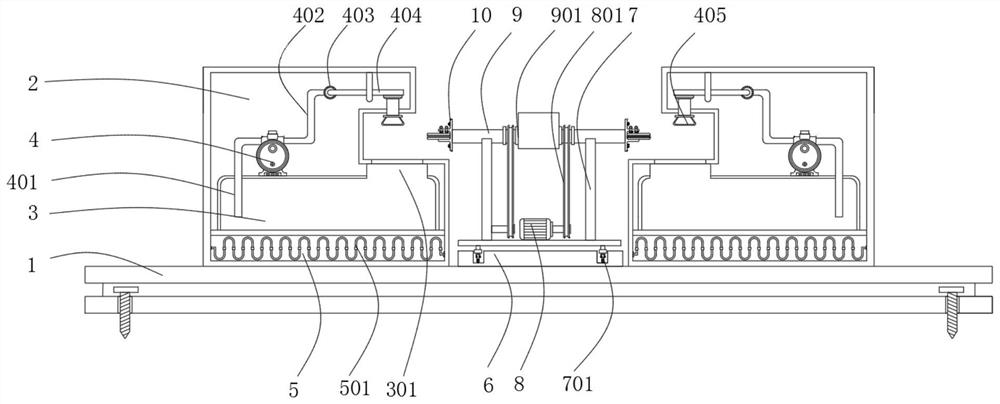

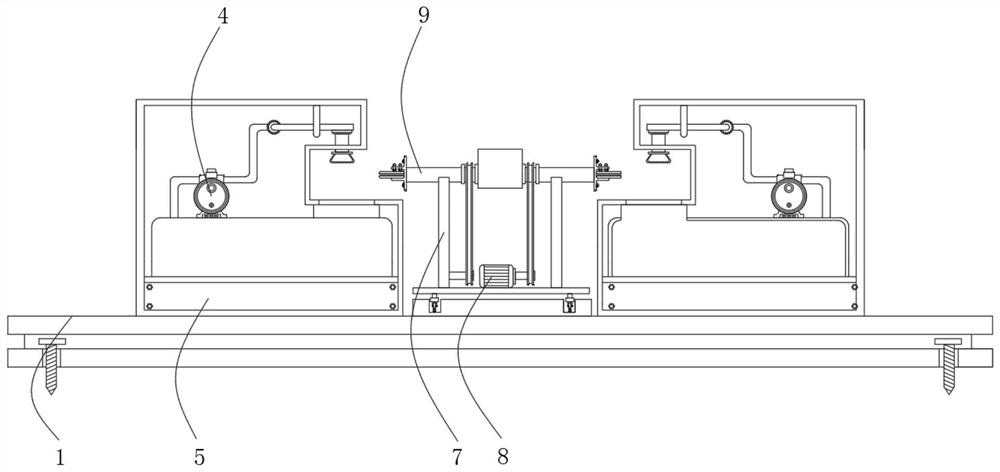

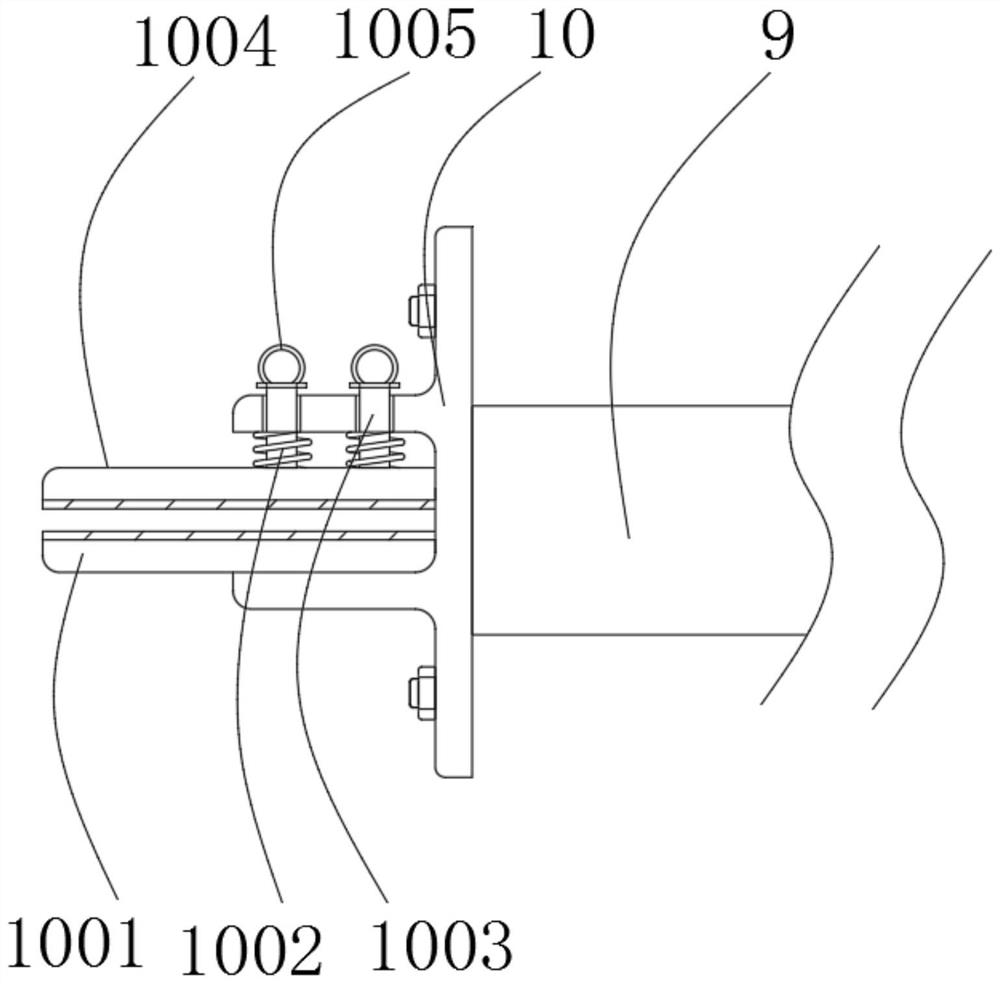

[0024] Example 1, such as Figure 1-3 As shown, the present invention provides a glue coating device for electronic components, including a bottom plate 1, two housings 2 are welded and installed on the top of the bottom plate 1, a slide rail 6 is welded on the top of the bottom plate 1, and the slide rail 6 is located between the two shells 2 Between the inner side of the slide rail 6, the top of the slide rail 6 is slidably fitted with a bracket 7, and the bottom of the bracket 7 is fixed with a pulley 701 by bolts, and the top of the bracket 7 is installed with a shaft 9, and the two ends of the shaft 9 are fixed with tight bolts. Firmware 10.

[0025] Let's talk about the specific settings and functions of the bracket 7, the fastener 10, the heating chamber 5 and the water pump 4 below.

[0026] Such as figure 1 and figure 2 As shown, the top of the bracket 7 is equipped with a shaft 9, the two ends of the shaft 9 are fixed with fasteners 10 by bolts, the top of the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com