A remote power supply voltage compensation method

A technology of power supply voltage and compensation method, which is applied in the direction of high-efficiency power electronic conversion, electrical components, and adjustment of electrical variables, etc. It can solve problems such as cost increase, equipment overvoltage, and equipment damage, and achieve voltage stability and avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

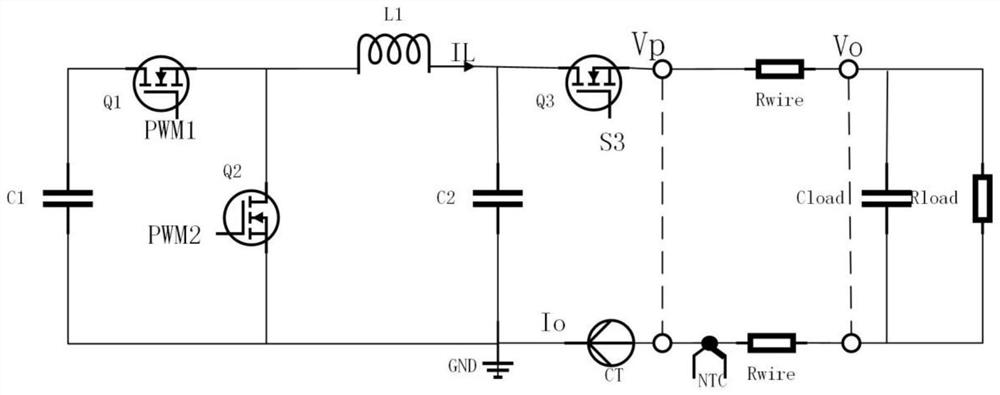

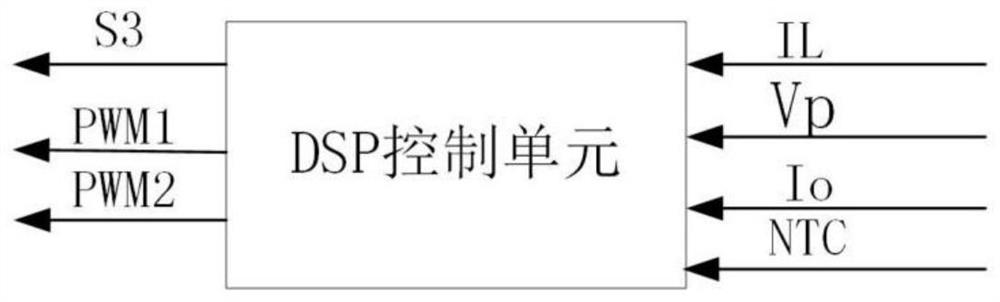

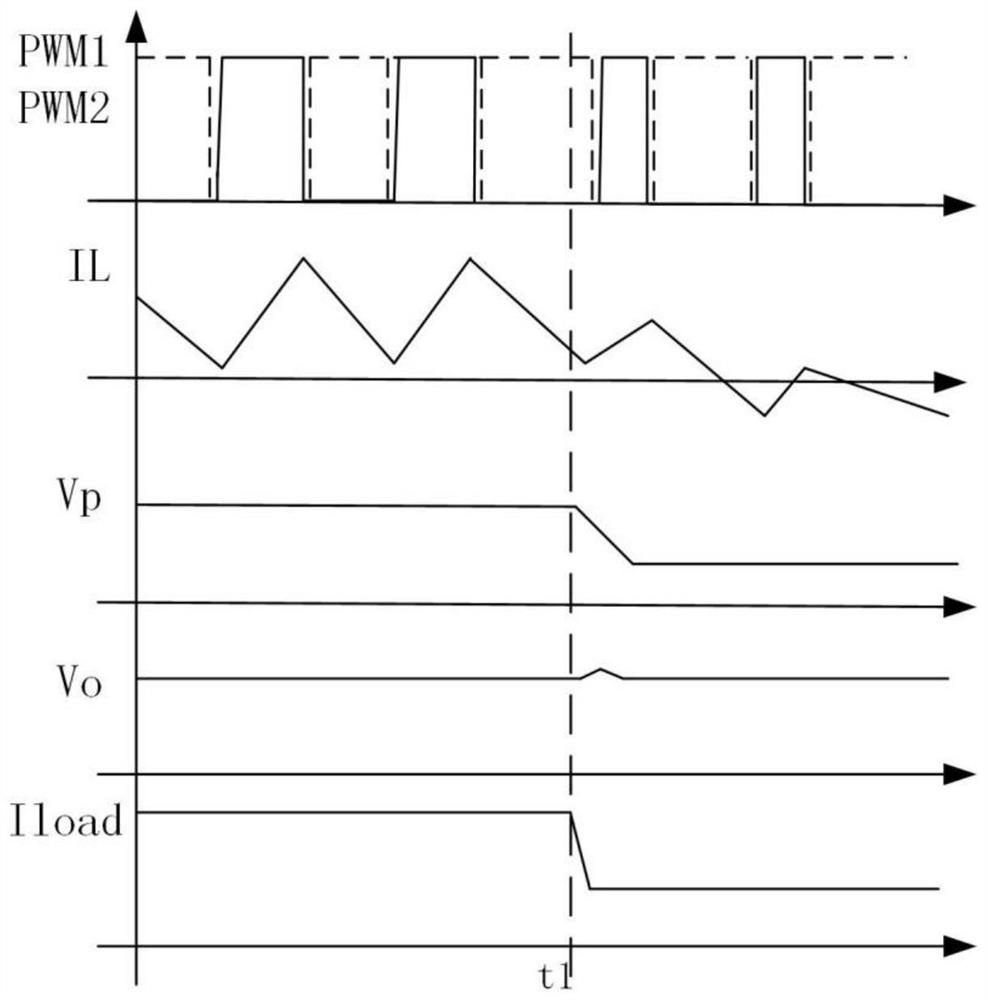

[0021] Such as Figure 1 to Figure 2 As shown, a remote power supply voltage compensation system includes:

[0022] 1. The bidirectional DC converter based on the synchronous BUCK topology is used as the power supply voltage source, of course other bidirectional topologies can also be used;

[0023] 2. MOSFET-based switch Q3 cuts off the power supply of external equipment in time when overcurrent occurs;

[0024] 3. Cable line impedance parameter identification module, used for online detection of line impedance parameters;

[0025] 4. The line temperature acquisition module of the line temperature acquisition module (or other temperature sensors), which is used for temperature compensation of line impedance;

[0026] 5. The DSP control unit completes the function control and realization of the above modules.

[0027] The remote power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com