Hollow floor system with stiffening columns and capable of improving local pressure-bearing performance of plate surface, box body and construction method of hollow floor system

A technology of hollow floor and construction method, which is applied to the processing of floors, building materials, building components, etc. It can solve problems such as undetectable and hidden safety hazards, and achieve the effects of reducing damage, improving bearing capacity, and strong compressive capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

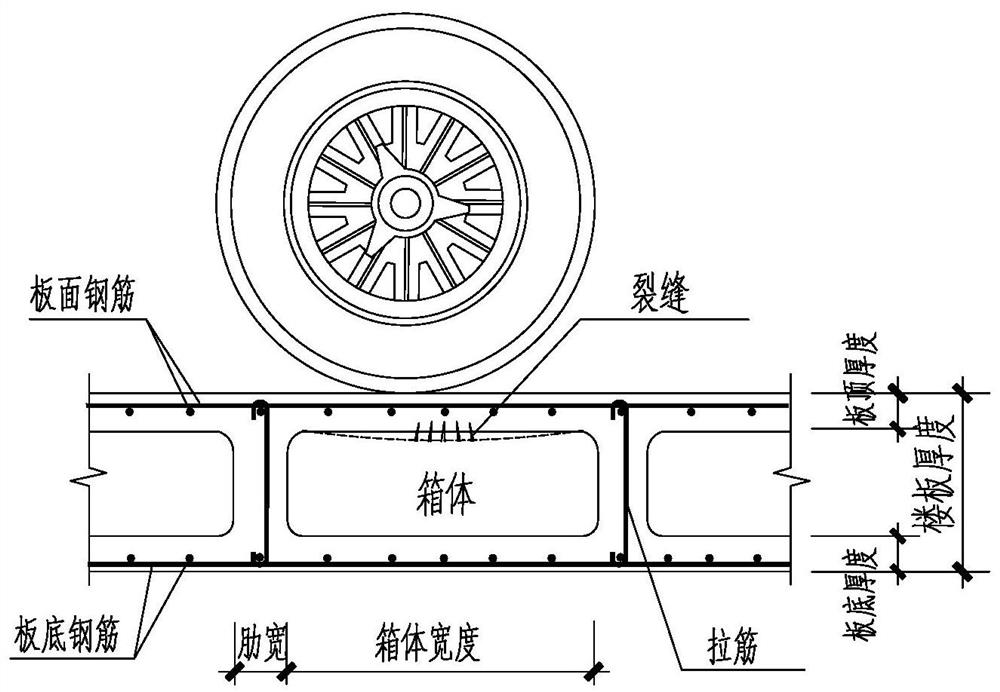

[0032] The present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments, and the purpose and effect of the present invention will become clearer. It should be understood that the specific embodiments described here are only used to explain the present invention and are not intended to limit the present invention.

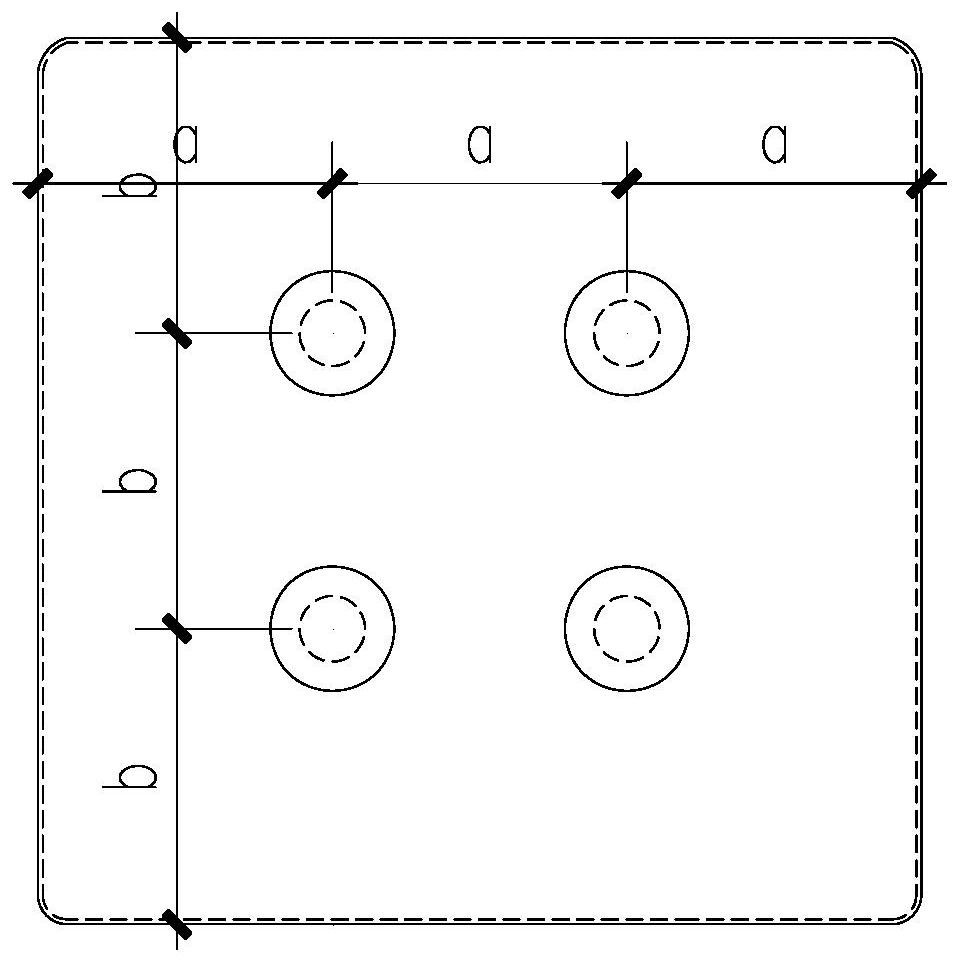

[0033] like figure 2 and image 3 As shown, the box body for the hollow floor of the present invention is a thin-walled hollow square box, and the box body is provided with several parallel vertical through stiffening holes.

[0034] In order to further improve the pressure-bearing performance of the upper slab of the floor and greatly increase the bearing capacity of the roof of the box area, the vertically penetrating stiffening holes are arranged in an array or in a quincunx shape. The upper and lower parts of the stiffening hole are provided with arc-shaped diversion holes, and the diameter of the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com