Phosphorus removal agent for sewage treatment and preparation method thereof

A technology of sewage treatment and phosphorus removal agent, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of increasing phosphorus removal cost, small adsorption capacity, and harsh service conditions. , to achieve the effect of improving the adsorption capacity and adsorption rate, fast flocculation and sedimentation speed, and firm flocculation sediment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A phosphorus removal agent for sewage treatment, comprising the following raw materials in parts by weight:

[0059] 45-55 parts of ferrous sulfate pentahydrate,

[0060] 12-16 parts of polyaluminum chloride,

[0061] 20-27 parts of polymerized aluminum iron silicate,

[0062] 25-33 parts of hydroxyl iron modified montmorillonite.

[0063] Preferably, the dephosphorization agent for sewage treatment includes the following raw materials in parts by weight:

[0064] 50 parts of ferrous sulfate pentahydrate,

[0065] 14 parts of polyaluminum chloride,

[0066] Polymerized aluminum iron silicate 23.5 parts,

[0067] 29 parts of hydroxyl iron modified montmorillonite.

[0068] Preferably, the preparation method of described hydroxyl iron modified montmorillonite comprises the steps:

[0069] 1) Preparation of hydroxy iron sol:

[0070] 11) dissolving ferric chloride in deionized water to form an aqueous ferric chloride solution;

[0071] 12) adding the sodium hydrox...

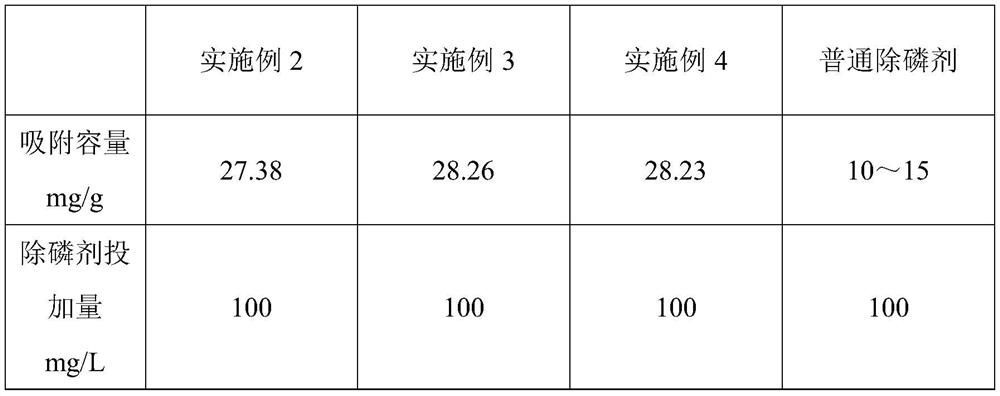

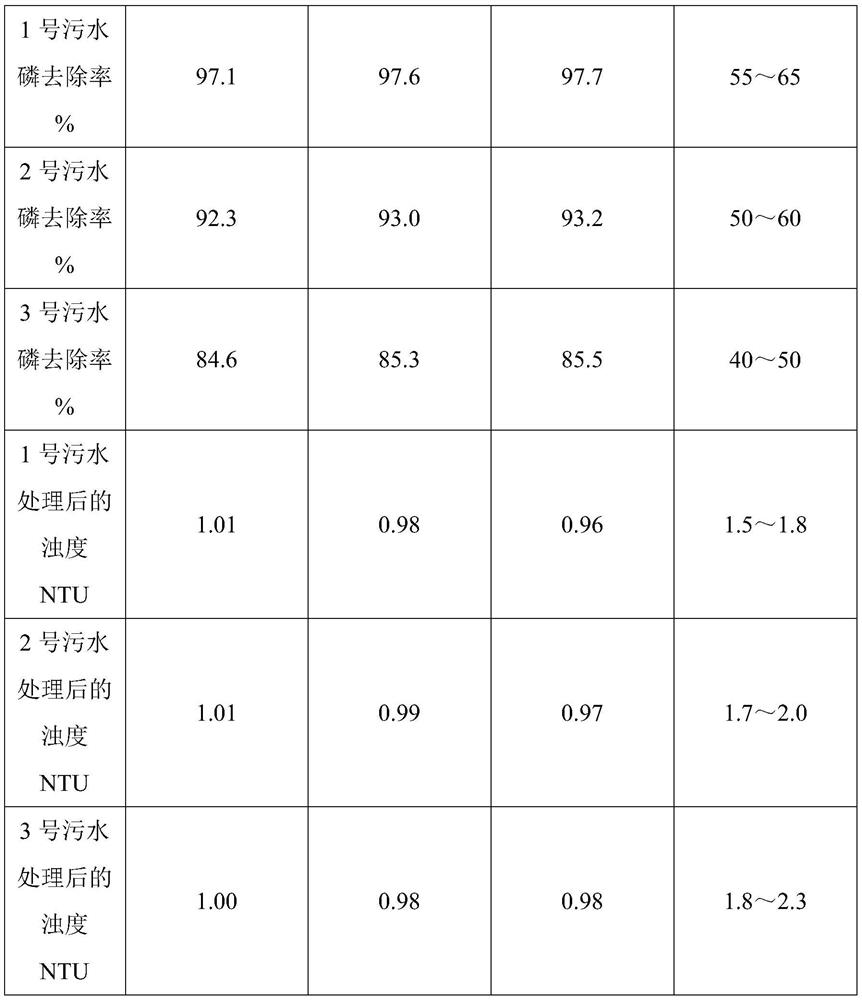

Embodiment 2

[0090] A phosphorus removal agent for sewage treatment, comprising the following raw materials in parts by weight:

[0091] 45 parts of ferrous sulfate pentahydrate,

[0092] 12 parts of polyaluminum chloride,

[0093] Polymerized aluminum iron silicate 20 parts,

[0094] Hydroxyl iron modified montmorillonite 25 parts.

[0095] In the present embodiment, the preparation method of the hydroxy iron modified montmorillonite comprises the following steps:

[0096] 1) Preparation of hydroxy iron sol:

[0097] 11) dissolving ferric chloride in deionized water to form an aqueous ferric chloride solution;

[0098] 12) adding the sodium hydroxide aqueous solution dropwise to the ferric chloride aqueous solution, stirring while adding dropwise, after the dropwise addition, continue stirring for 30min to obtain the hydroxyiron sol;

[0099] 2) Preparation of hydroxyl iron modified montmorillonite:

[0100] 21) Stirring and dispersing the montmorillonite in the mixed solvent, feedi...

Embodiment 3

[0117] A phosphorus removal agent for sewage treatment, comprising the following raw materials in parts by weight:

[0118] 55 parts of ferrous sulfate pentahydrate,

[0119] 16 parts of polyaluminum chloride,

[0120] Polymerized aluminum iron silicate 27 parts,

[0121] 33 parts of hydroxyl iron modified montmorillonite.

[0122] In the present embodiment, the preparation method of the hydroxy iron modified montmorillonite comprises the following steps:

[0123] 1) Preparation of hydroxy iron sol:

[0124] 11) dissolving ferric chloride in deionized water to form an aqueous ferric chloride solution;

[0125] 12) adding the sodium hydroxide aqueous solution dropwise to the ferric chloride aqueous solution, stirring while adding dropwise, after the dropwise addition, continue stirring for 50min to obtain the hydroxyiron sol;

[0126] 2) Preparation of hydroxyl iron modified montmorillonite:

[0127] 21) Stirring and dispersing the montmorillonite in the mixed solvent, fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com