High-strength waterproof breathable carbon fiber composite fabric and preparation method thereof

A waterproof, breathable, composite fabric technology, applied in carbon fiber, antifouling/underwater coatings, fiber treatment, etc., can solve the problems of insufficient performance of carbon fiber composite materials and narrow application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

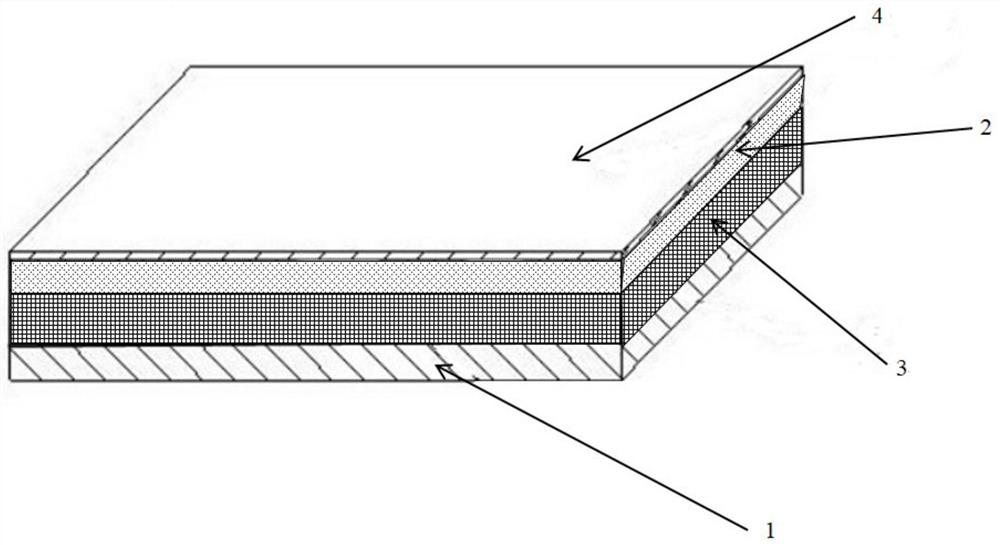

[0028] A high-strength waterproof and breathable carbon fiber composite fabric, comprising a bottom lining layer 1, an elastic layer 2 is arranged on the bottom lining layer 1, and the carbon fiber fabric layer 3 is bonded between the bottom lining layer 1 and the elastic layer 2. into; the top of the elastic layer 2 is provided with a wear-resistant water-proof layer 4 .

[0029] The bottom liner layer 1 is a woven, knitted or warp knitted fabric of cotton, linen, polyester or their blends.

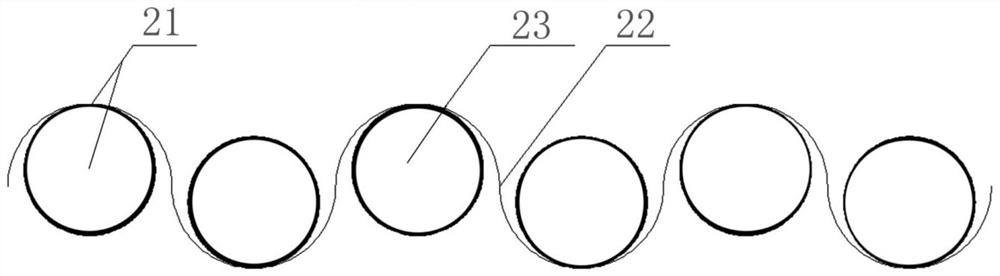

[0030] The elastic layer 2 is composed of warp threads 21 and weft threads 22; the warp threads 21 are bi-component polyester filaments PET / PTT23; the weft threads 22 are blended yarns of polyester fibers and natural bamboo fibers.

[0031] The reinforced carbon fiber fabric layer 3 is prepared by the following method:

[0032] 1) After mixing nano-titanium dioxide and nano-silicon dioxide, add them to 100 times the weight of absolute ethanol, and disperse them evenly by ultrasonic to o...

Embodiment 2

[0043] A high-strength waterproof and breathable carbon fiber composite fabric, comprising a bottom lining layer 1, characterized in that an elastic layer 2 is arranged on the bottom lining layer 1, and a reinforced carbon fiber fabric layer is passed between the bottom lining layer 1 and the elastic layer 2 3 bonded; above the elastic layer 2 is provided with a wear-resistant water-proof layer 4.

[0044] The bottom liner layer 1 is a woven, knitted or warp knitted fabric of cotton, linen, polyester or their blends.

[0045] The elastic layer 2 is composed of warp threads 21 and weft threads 22; the warp threads 21 are bi-component polyester filaments PET / PTT23; the weft threads 22 are blended yarns of polyester fibers and natural bamboo fibers.

[0046] The reinforced carbon fiber fabric layer 3 is prepared by the following method:

[0047]1) After mixing nano-titanium dioxide and nano-silicon dioxide, add them to 100 times the weight of absolute ethanol, and disperse them ...

Embodiment 3

[0058] A high-strength waterproof and breathable carbon fiber composite fabric, comprising a bottom lining layer 1, characterized in that an elastic layer 2 is arranged on the bottom lining layer 1, and a reinforced carbon fiber fabric layer is passed between the bottom lining layer 1 and the elastic layer 2 3 bonded; above the elastic layer 2 is provided with a wear-resistant water-proof layer 4.

[0059] The bottom liner layer 1 is a woven, knitted or warp knitted fabric of cotton, linen, polyester or their blends.

[0060] The elastic layer 2 is composed of warp threads 21 and weft threads 22; the warp threads 21 are bi-component polyester filaments PET / PTT23; the weft threads 22 are blended yarns of polyester fibers and natural bamboo fibers.

[0061] The reinforced carbon fiber fabric layer 3 is prepared by the following method:

[0062] 1) After mixing nano-titanium dioxide and nano-silicon dioxide, add them to 100 times the weight of absolute ethanol, and disperse them...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com