Intelligent auxiliary system for railway shunting operation

An auxiliary system and shunting technology, applied in the field of integrated systems, can solve the problems of losing the efficiency of real-time management and real-time control, relying on manual management mode, and unable to achieve immediacy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

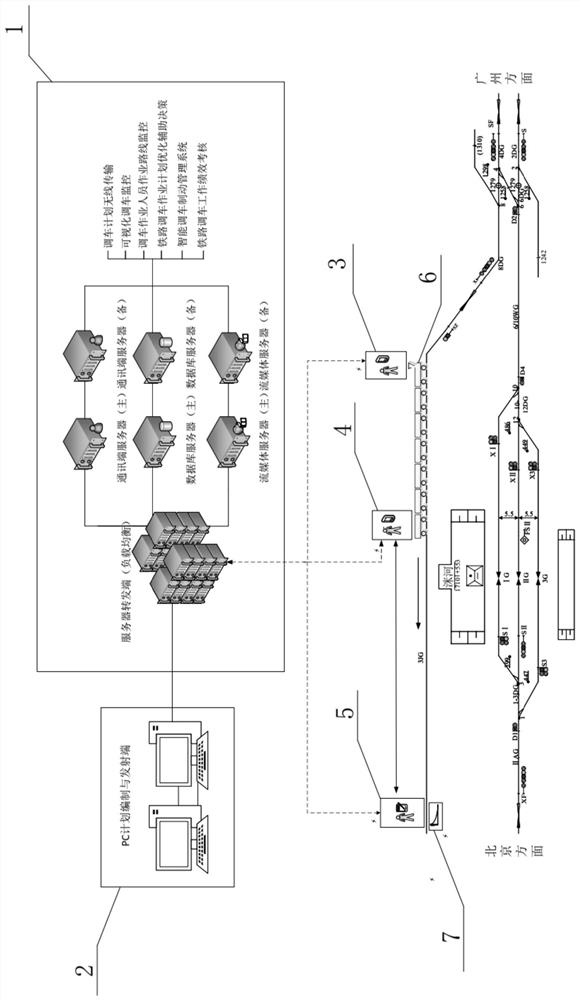

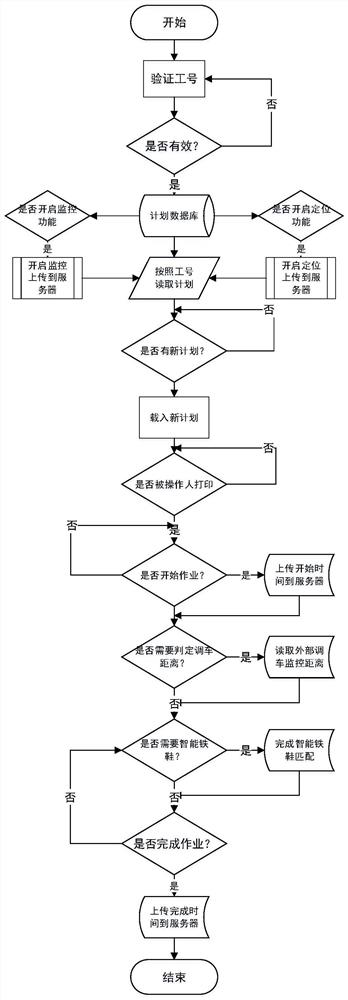

[0044] Each embodiment in this specification is described in a progressive manner, each embodiment focuses on the difference from other embodiments, and the same and similar parts of each embodiment can be referred to each other. figure 1 The functional block diagram in shows the intelligent auxiliary system for shunting operation of the present invention. As can be seen from the figure, the system includes the entire control subsystem, which are specifically: vehicle operation auxiliary management platform, shunting plan wireless transmission system, push operation distance recognition system, data forwarding platform, visual shunting monitoring system, shunting Operating route monitoring system for operators, auxiliary decision-making for optimization of railway shunting operation plan, intelligent iron shoe braking management, hook plan execution monitoring and management systems, etc. It includes PC plan preparation and transmitting end, signal forwarding server end, infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com