Plate impact test device

An impact test and plate technology, which is applied in measuring devices, analytical materials, instruments, etc., to achieve the effect of effective and reliable experimental data and simple and easy methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

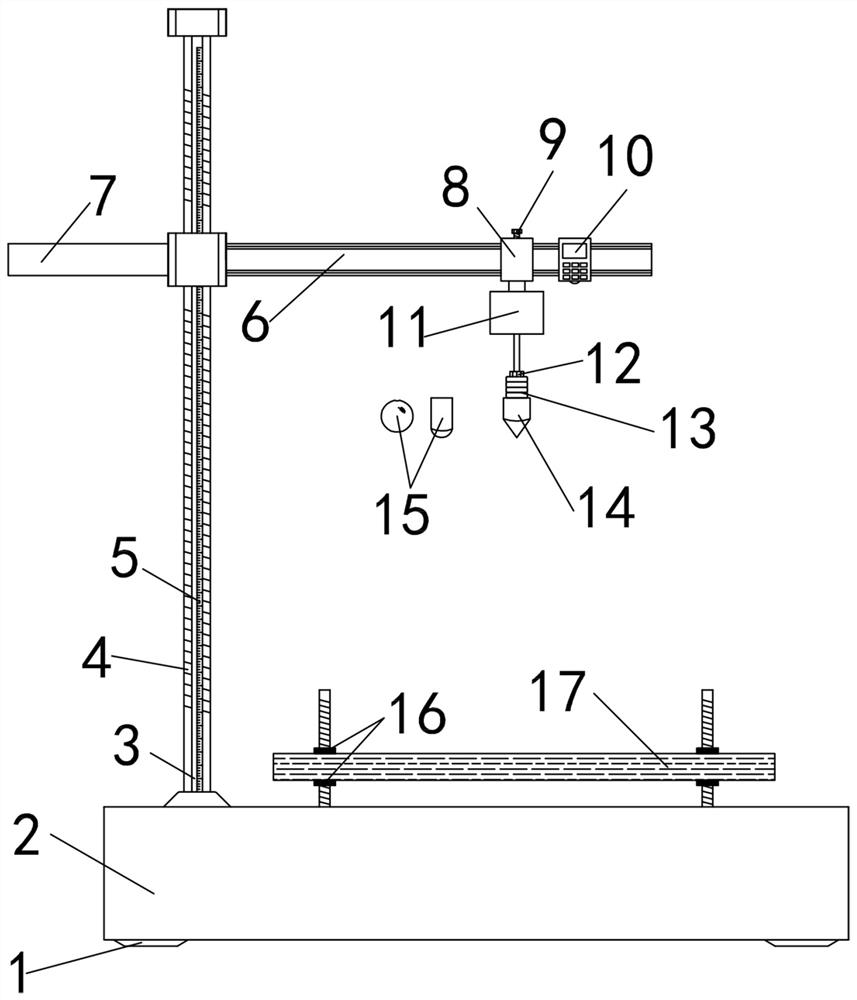

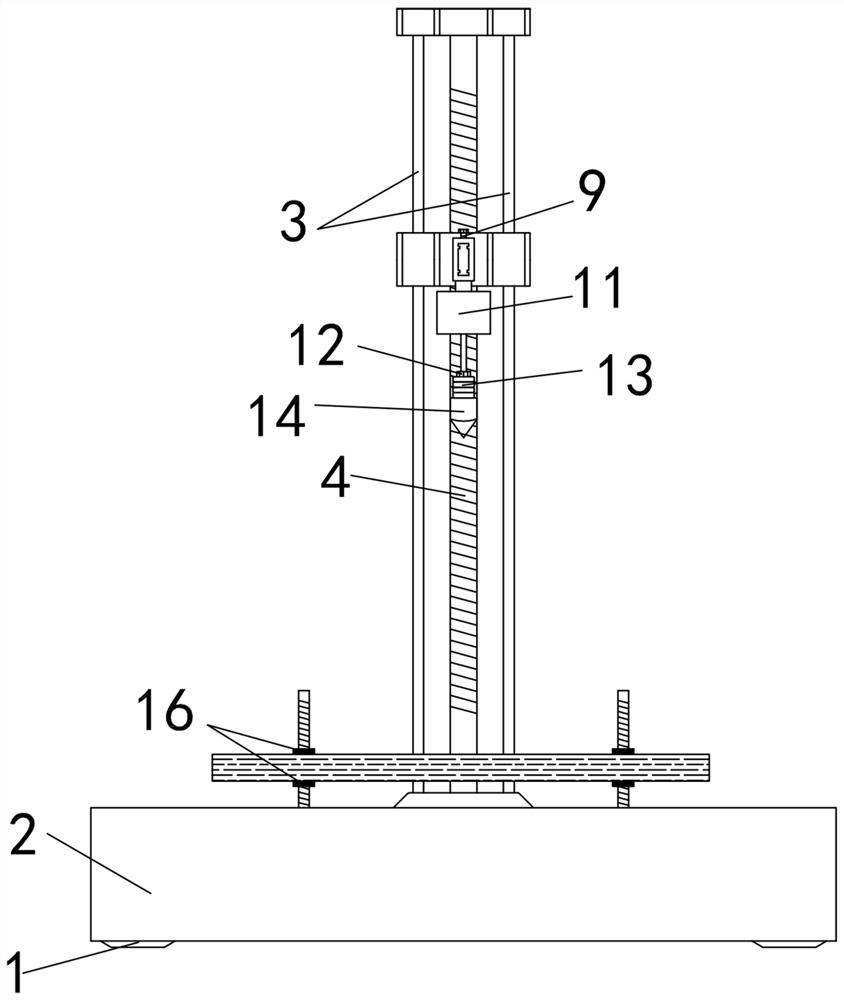

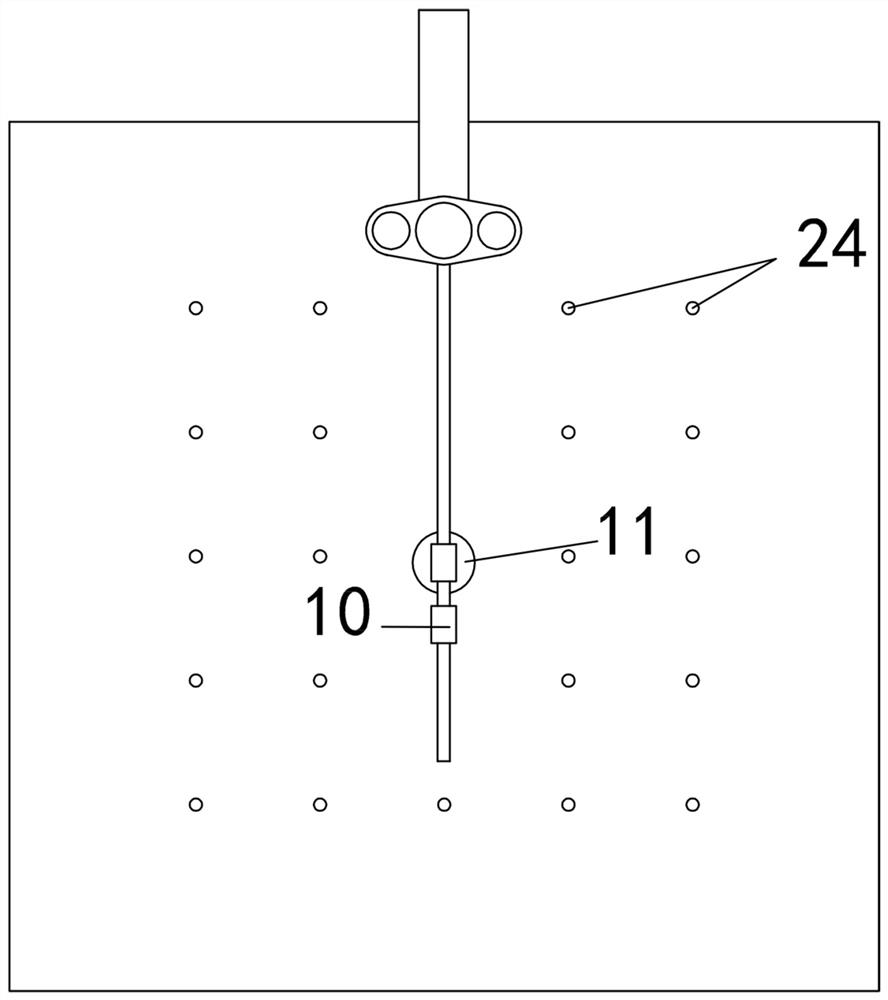

[0034] Embodiment 1: This embodiment provides a plate impact test device, including an improved structure for quick replacement of various impact hammers. Figure 1-Figure 3 A simplified structural diagram of the experimental setup is shown, Figure 4 The assembly relationship of the impact head clamping assembly is shown.

[0035] from figure 1 It can be seen that the experimental device mainly includes a fixed foot support 1, a base 2, a limit rod 3, a transmission shaft 4, a height gauge 5, a liftable horizontal rod 6, a horizontal counterweight rod 7, a horizontal adjustment bracket 8, a fastening Screw 9, laser rangefinder 10, magnetic fixture 11, etc. Specifically, the fixed legs 1 are located at the four top corners below the base to support the base 2, and the left side of the base 2 (such as figure 1 ) is erected and fixed with double parallel limit rods 3 (such as figure 2 ), there is a transmission shaft 4 vertically fixed on the upper part of the base 2 betwee...

Embodiment 2

[0042] Embodiment 2: improve on the basis of embodiment 1, adopt such as figure 2 In the plate impact test device shown, a sliding sleeve is also installed on the slider, and the lifting horizontal rod 6 is fixed on one side of the sliding sleeve, so that the sliding sleeve can move longitudinally along the sliding block, and then drive the lifting horizontal rod 6 together. Pan vertically. This design can not only fix the liftable horizontal bar 6 and the sliding sleeve at the center position of the slider, which has the same effect as that of embodiment 1, but also can change the longitudinal position of the liftable horizontal bar 6 so that other parts of the plate to be tested location to test.

Embodiment 3

[0043] Embodiment 3: On the basis of Embodiment 1 or 2, a diamond-shaped body 41 is fixed on the upper end of the central combination rod, such as Figure 13 As shown, at the same time, a Y-shaped oblique slideway 39 is provided at the center of the body of the magnetic fixture 11, and the oblique slider 40 is matched therein. When the oblique sliders 40 on both sides lose their magnetism, they slide down and are supported on the The lower slopes on both sides of the rhombus 41, when both sides are inclined to the slide block 40 after being magnetized, slide upwards and break away from the lower slopes on both sides of the rhombus 41 to make the central combination rod and the impact head clamping assembly assembly fall down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com