Rotary excavating and drilling construction method relating to deep concrete blocks and gravel layer and special rotary excavating and drilling equipment

A technology of concrete block and gravel layer, applied in drilling equipment and methods, drilling equipment, earthwork drilling, etc., can solve the problem that the backfill layer cannot achieve the effect of compaction of the soil layer, the stability of the soil body cannot be guaranteed, noise and noise For the problem of high soil disturbance, it can achieve the effect of low noise, fast construction speed and high environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention relates to a construction method of a dry-work hole-forming cast-in-place pile rotary drilling rig in deep concrete blocks and gravel layers. The main construction facilities of the invention include:

[0024] 1. Sany Heavy Industry SR220C rotary drilling rig has a drilling diameter of 600-2300mm, a maximum drilling depth of 66000mm, and a maximum pressure of 180kn.

[0025] 2. Main winch, the lifting force of the main winch is 240kn, the diameter of the wire rope is 28mm, and the hoisting speed is 70m / min.

[0026] 3. Power head, its maximum output torque is 220kn.m.

[0027] 4. Drill pipe, the diameter of which is 440mm.

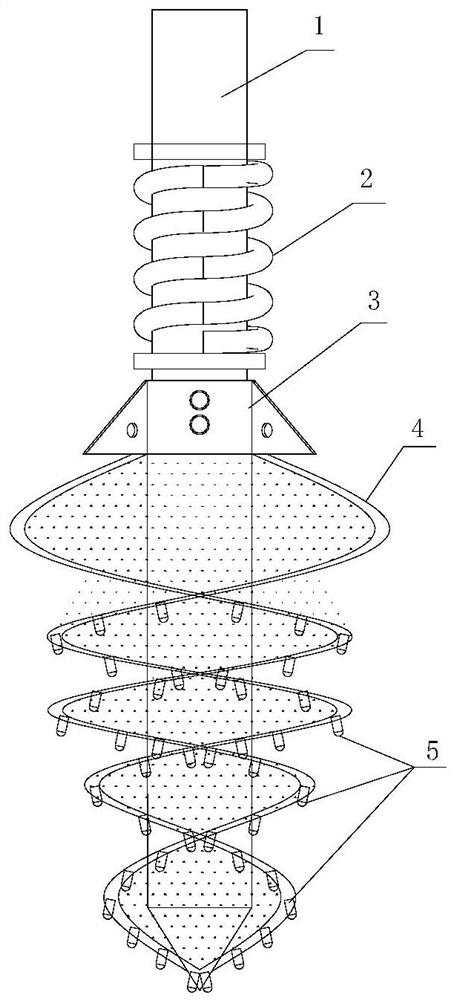

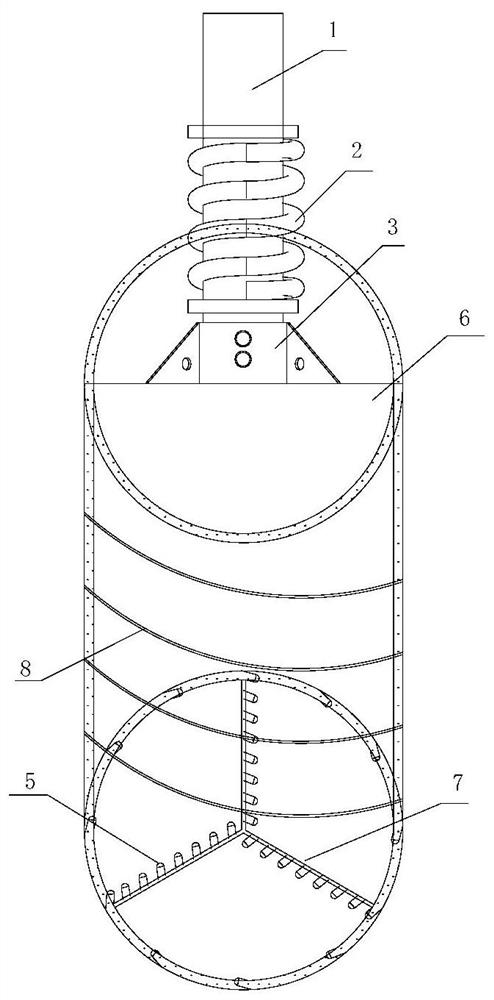

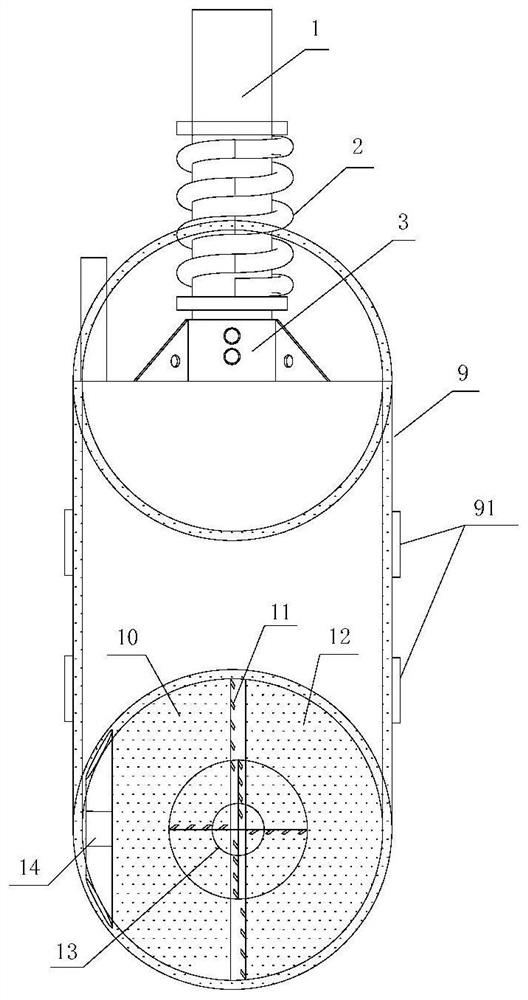

[0028] Five, such as figure 1 Shown, rock auger bit 4, its upper end is the connection end 3 that links to each other with drill pipe 1, and the drill pipe spring 2 is set on the connection end 3, and auger bit is arranged below the connection end, and the shape of the drill bit is a spiral cone type, and the auger bit includes two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com