System and method for breaking through limitation of single weft insertion number of air-jet loom

An air-jet loom, quantitative technology, applied in the direction of looms, textiles, textiles and papermaking, etc., can solve the problems of influence, loss of high-efficiency features of multi-weft insertion, etc., and achieve the effect of increasing production and stable and reliable working process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

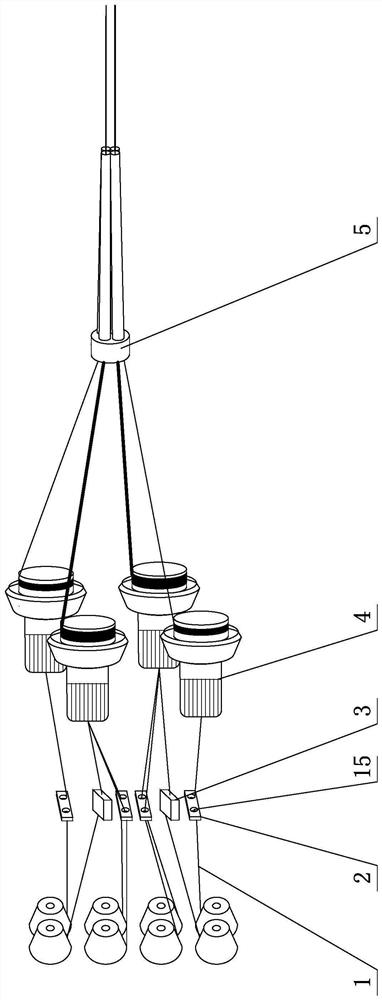

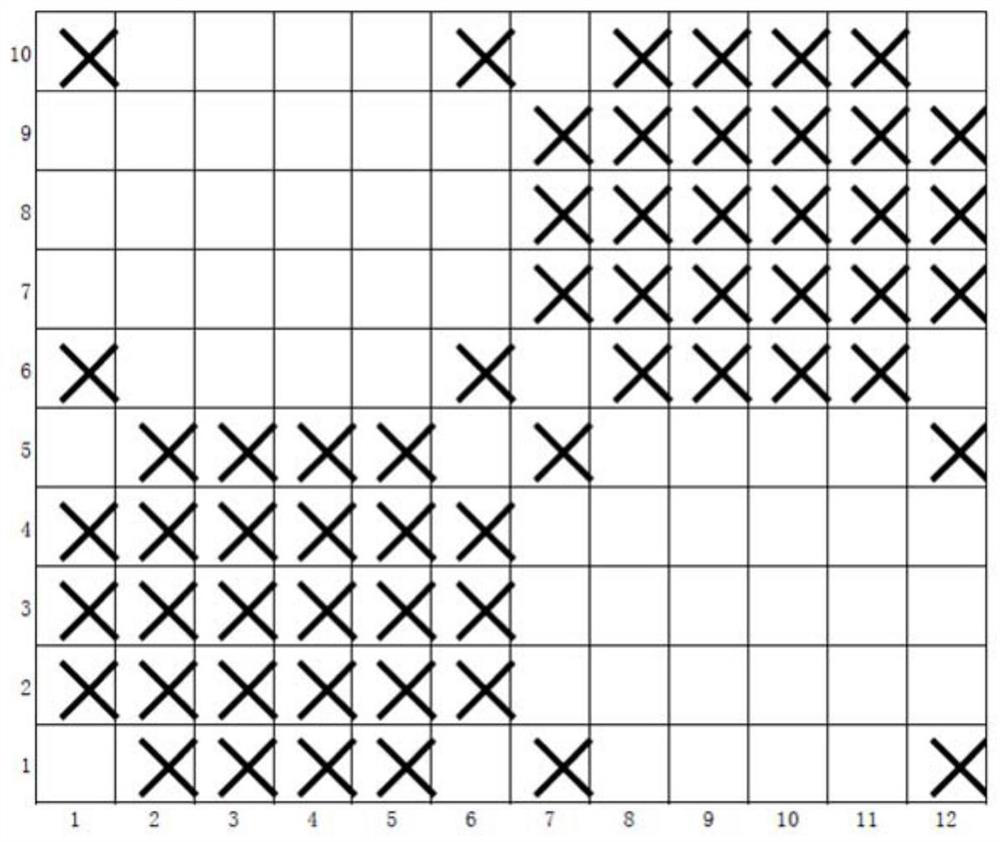

[0034] Embodiment 1, with organization chart as image 3 Taking three wefts as an example in the through-hole weave, the heald is drawn in the way of flying through, and the weft yarns are alternately drawn with three wefts and one weft to form a through-hole fabric:

[0035] A method for breaking through the limitation of the single weft insertion quantity of an air-jet loom, comprising the following steps,

[0036] Step 1, arranging the weft yarn 1, placing the weft yarn 1 required for production on the weft creel;

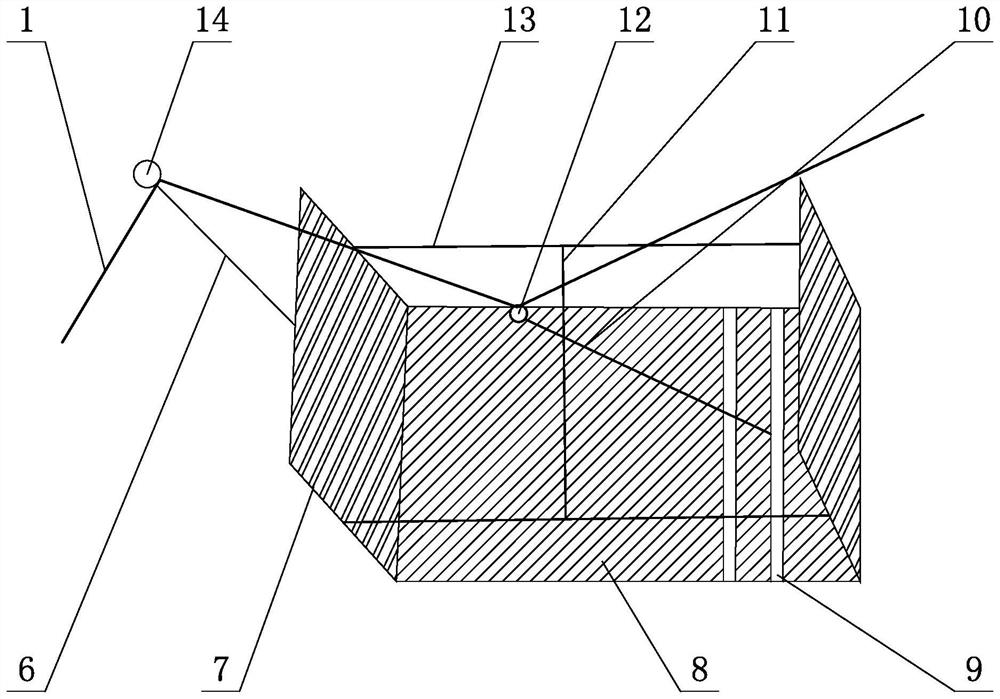

[0037] Step 2, the three weft yarns 1 are passed through the guide holes 15 of two existing weft detectors 2 and the guide holes 14 and pinholes 12 of a weft stop detection mechanism 3 respectively, and then the three weft yarns 1 are combined Store and wind on one of the weft feeders 4, insert a part of the weft yarn 1 through the yarn guide hole 15 of the existing weft finder 2, and then store and wind this weft yarn 1 on another weft feeder 4 ;

[0038] St...

Embodiment 2

[0042]Embodiment 2, with organization chart as Figure 6 Take the 4 / 4 basket weave as an example, adopt the method of threading through the heddle, and the four wefts of the weft thread alternately form a square fabric:

[0043] A method for breaking through the limitation of the single weft insertion quantity of an air-jet loom, comprising the following steps,

[0044] Step 1, arranging the weft yarn 1, placing the weft yarn 1 required for production on the weft creel;

[0045] Step 2, the eight weft yarns 1 are divided into two groups of four, the first group of four weft yarns 1 respectively pass through the guide holes 15 of the two existing weft detectors 2 and the guide holes 14 of the two weft stop detection mechanisms 3 and pinhole 12, and then the four weft yarns 1 are stored and wound together on one of the weft feeders 4 of a group of weft feeders 4, and the other group of four weft yarns 1 is stored and wound on another weft feeder in the same way 4 on;

[0046]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com