High-wear-resistance and low-flash-point anti-glare film and preparation method thereof

An anti-glare film, low flash point technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problem of wear resistance and flash point, the wear resistance is not substantially improved, the wear resistance of anti-glare film Insufficient and other problems, to achieve the effect of good flash point, lower flash point, and close refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

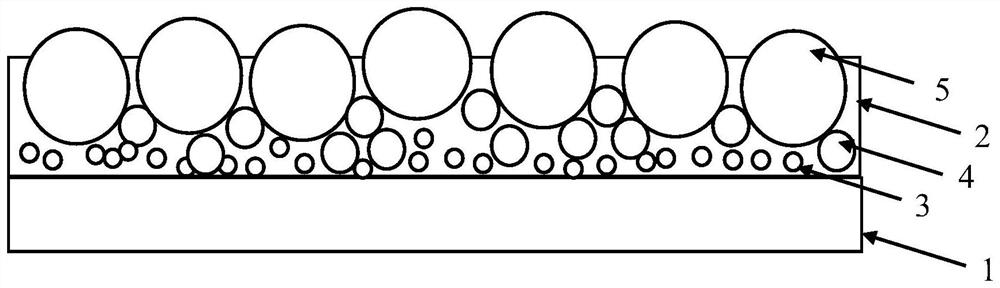

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing an anti-glare film with high wear resistance and low flash point, comprising the following steps:

[0033] S1. Mix the following components by weight percentage to prepare an anti-glare coating solution: 15%-70% acrylate prepolymer, 5%-40% acrylate monomer, 0.5%-10% anti-glare Particles, 1%-6% photoinitiator, 0.1%-0.5% dispersant, 0.1%-0.5% leveling agent, 0.1%-0.6% fluorine-containing additive, 20%-75% solvent;

[0034] S2. Coating the anti-glare coating liquid on the base material, after baking and drying, and then performing UV curing to obtain the anti-glare film with high wear resistance and low flash point;

[0035] Wherein, the anti-glare particles include the first anti-glare particles, the second anti-glare particles and the third anti-glare particles, and the particle diameters of the first anti-glare particles, the second anti-glare particles and the third anti-glare particles increase sequentially. large, and th...

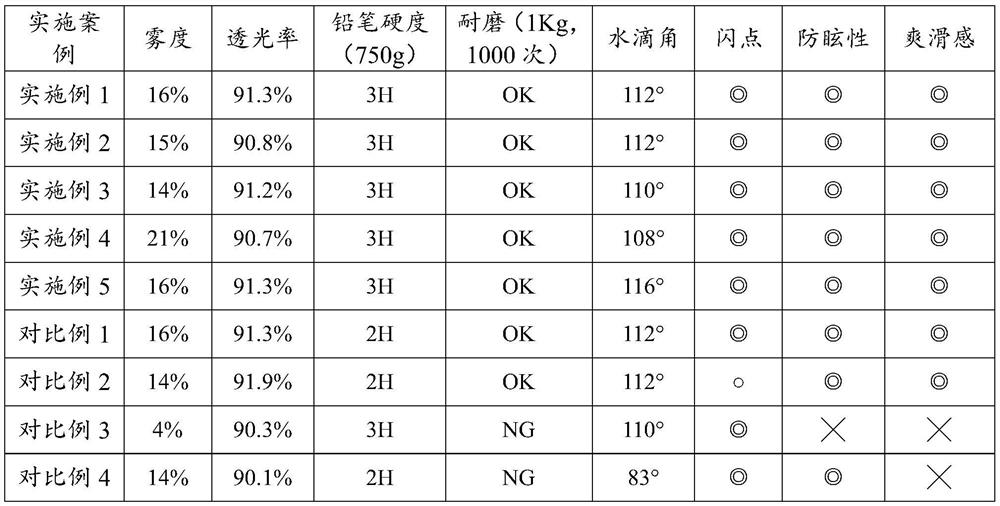

Embodiment 1

[0053] 1. Preparation of coating solution

[0054] In 200 parts of propylene glycol methyl ether, add 50 parts of nine-functional urethane acrylic resin oligomer CN9013NS (manufactured by Sartomer, with a refractive index of 1.49) and 20 parts of hexafunctional acrylate monomer DPHACNS, made by Sartomer, with a refractive index of 1.49 ), after high-speed stirring and dissolving, add 4 parts of photoinitiator 184 (manufactured by Tianjin Tianjiao Chemical Co., Ltd.) and 1 part of photoinitiator TPO (manufactured by Tianjin Tianjiao Chemical Co., Ltd.), then add 1 part of antiglare particle PMMA particle MX- 180TA (Japan Soken Chemical, particle size 1.8 μm, refractive index 1.48) and 2 parts of anti-glare particles PMMA particles SHG-3 (Japan Soken Chemical, particle size 3 μm, refractive index 1.48) and 2 parts of anti-glare particles PMMA Particle MX-500 (Nippon Soken Chemical, particle size 5μm, refractive index 1.48), then add 1 part of leveling agent BYK-333 (Byk Chemical...

Embodiment 2

[0058] 1. Preparation of coating solution

[0059] In 200 parts of propylene glycol methyl ether, add 70 parts of nine-functional urethane acrylic resin oligomer CN9013NS (manufactured by Sartomer, refractive index 1.49) and 20 parts of hexafunctional acrylate monomer DPHACNS (manufactured by Sartomer, refractive index 1.49), after high-speed stirring and dissolving, add 4 parts of photoinitiator 184 (manufactured by Tianjin Tianjiao Chemical Co., Ltd.) and 1 part of photoinitiator TPO (manufactured by Tianjin Tianjiao Chemical Co., Ltd.), then add 1 part of antiglare particle PMMA particle MX -180TA (Soken Chemical, particle size 1.8μm, refractive index 1.48), 2 parts of anti-glare particles PMMA particles SHG-3 (Soken Chemical, particle size 3μm, refractive index 1.48) and 2 parts of anti-glare particles PMMA particles MX-500 (Japan Soken Chemical, particle size 5 μm, refractive index 1.48), then add 1 part of leveling agent BYK-333 (Bike Chemicals), 1 part of dispersant DIS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com