A preparation process of dty plied yarn with special luster

A preparation process and a technology for plied yarn, applied in the field of preparation technology of DTY plied yarn, can solve the problems of limited application, fabric handle, appearance, texture, luster and elasticity cannot meet high requirements, poor air permeability and hygroscopicity, etc., and achieve improvement. Comfort issues, good sparkle, improved hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

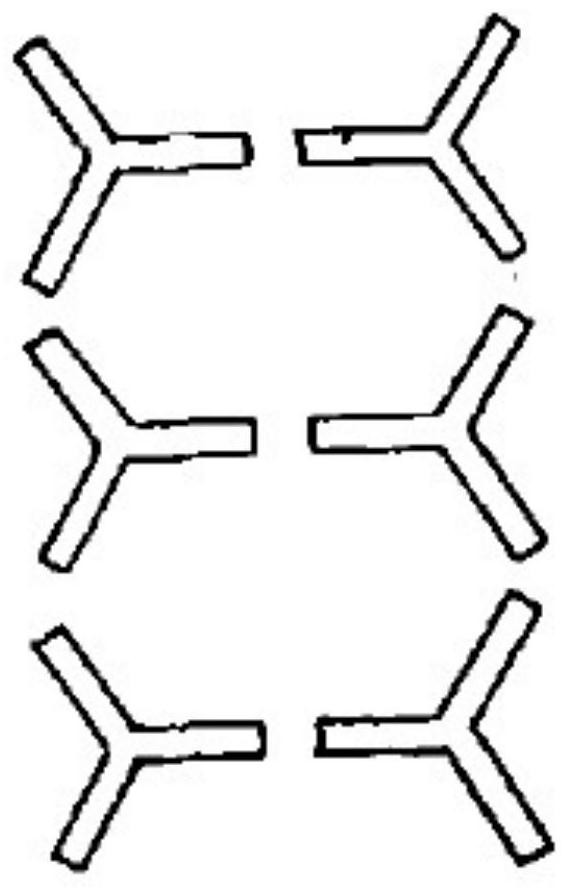

[0025] like figure 1 Shown, a kind of preparation technology of the DTY plied yarn with special luster, comprises the following steps:

[0026] Step (1), preparation of semi-dull FDY yarn: Pre-crystallize, homogenize and dry the polyester chips to obtain PET dry chips, and enter the screw extruder into the screw extruder, which is divided into eight zones. The temperature of the screw of the press is 250~275°C. After high-temperature melting, the melt is extruded, and the melt enters the spinning assembly for melt spinning. The spinning temperature is 245°C; figure 2 As shown, the spinneret holes on the spinneret in the spinning assembly are a flat structure formed of two rows of Y-shaped hole groups symmetrically arranged, each row of Y-shaped hole groups includes three Y-shaped holes, and two rows of Y-shaped holes The Y-shaped holes in the group are obliquely close to each other; the fine flow of melt ejected from the spinning assembly is solidified and cooled into filame...

Embodiment 2

[0031] like figure 1 Shown, a kind of preparation technology of the DTY plied yarn with special luster, comprises the following steps:

[0032] Step (1), preparation of semi-dull FDY yarn: Pre-crystallize, homogenize and dry the polyester chips to obtain PET dry chips, and enter the screw extruder into the screw extruder, which is divided into eight zones. The temperature of the screw of the press is 250~275°C. After high-temperature melting, the melt is extruded, and the melt enters the spinning assembly for melt spinning. The spinning temperature is 260°C; among them, such as figure 2 As shown, the spinneret holes on the spinneret in the spinning assembly are a flat structure formed of two rows of Y-shaped hole groups symmetrically arranged, each row of Y-shaped hole groups includes three Y-shaped holes, and two rows of Y-shaped holes The Y-shaped holes in the group are obliquely close to each other; the fine flow of melt ejected from the spinning assembly is solidified an...

Embodiment 3

[0037] like figure 1 Shown, a kind of preparation technology of the DTY plied yarn with special luster, comprises the following steps:

[0038] Step (1), preparation of semi-dull FDY yarn: Pre-crystallize, homogenize and dry the polyester chips to obtain PET dry chips, and enter the screw extruder into the screw extruder, which is divided into eight zones. The temperature of the screw of the press is 250~275°C. After high-temperature melting, the melt is extruded, and the melt enters the spinning assembly for melt spinning. The spinning temperature is 270°C; among them, such as figure 2 As shown, the spinneret holes on the spinneret in the spinning assembly are a flat structure formed of two rows of Y-shaped hole groups symmetrically arranged, each row of Y-shaped hole groups includes three Y-shaped holes, and two rows of Y-shaped holes The Y-shaped holes in the group are obliquely close to each other; the fine stream of melt ejected from the spinning assembly is solidified an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| rate of change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com