3D printer

A 3D printer and robotic arm technology, applied in coating devices, additive processing, etc., can solve the problems of nozzle aging, nozzle temperature rise, and high cost of construction, to increase the flow rate, ensure circulating flow, and increase spraying. effect of material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

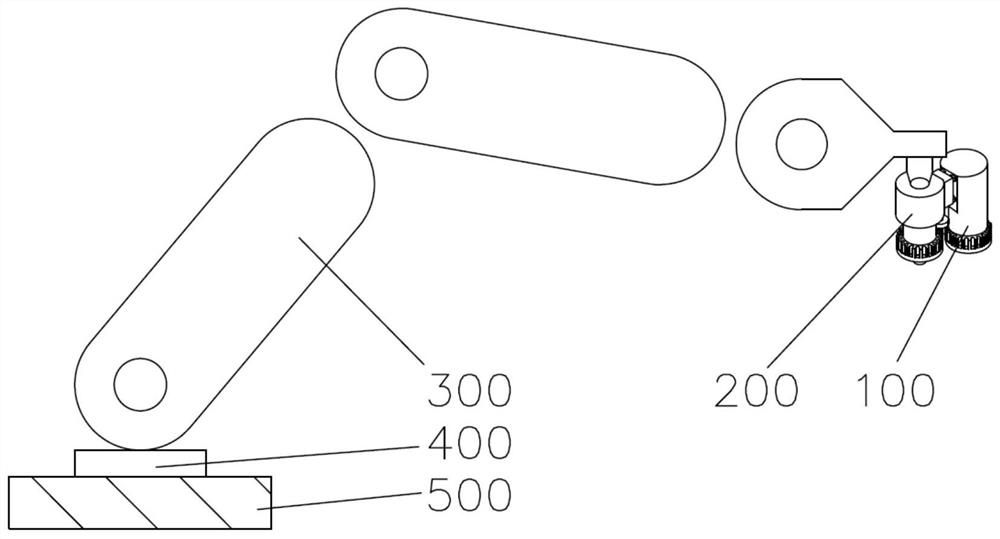

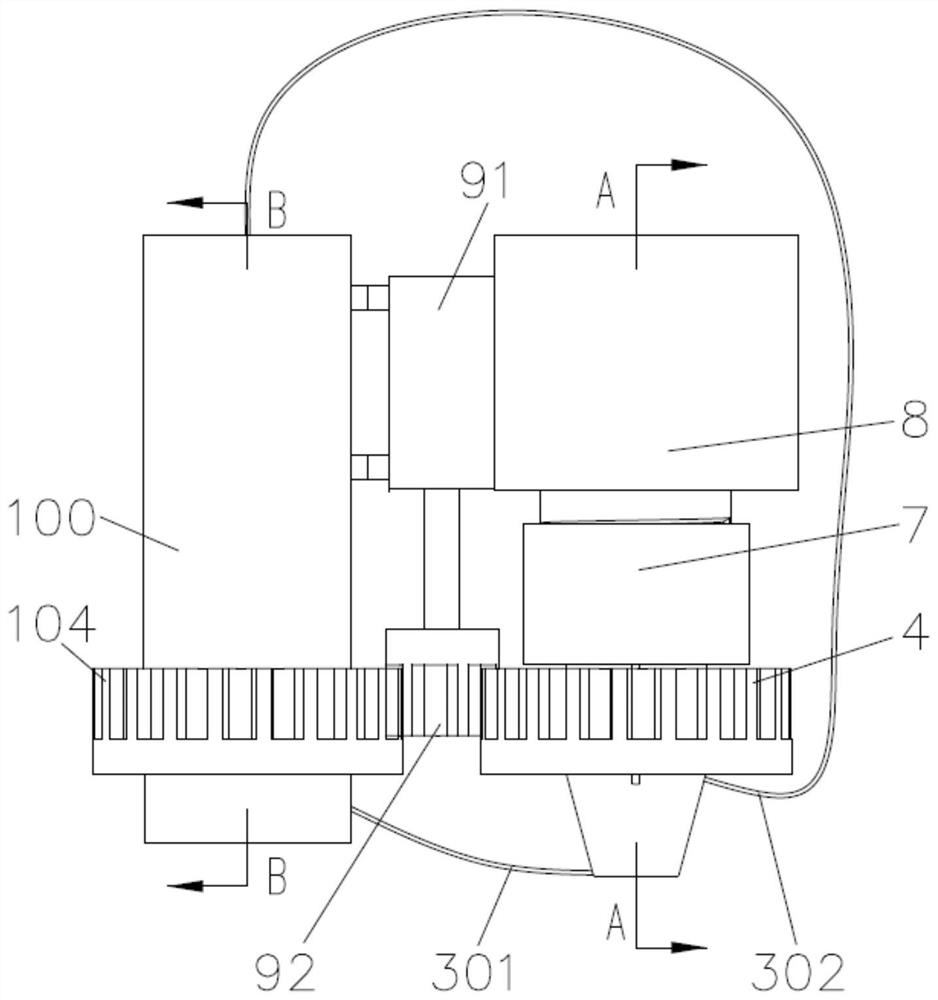

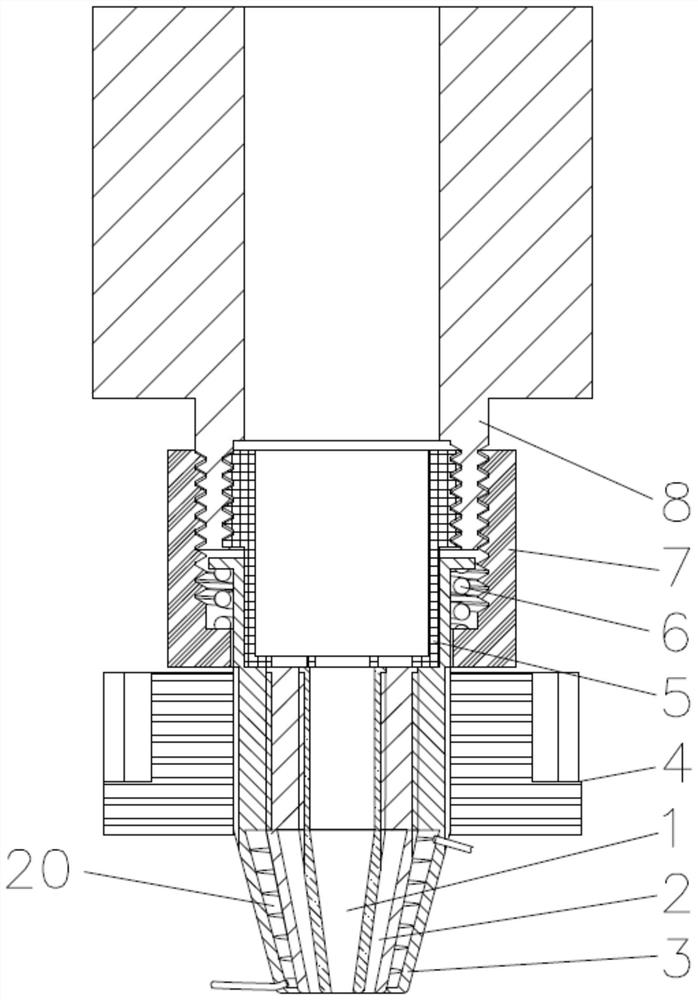

[0044] Such as Figure 1-12 As shown, a 3D printer is characterized in that it includes a fixed table 500, a rotating table 400, a mechanical arm 300, a nozzle assembly 200 and a cooling cycle assembly 100; the rotating table 400 is located above the fixed table 500 and the rotating table 400 is connected to the fixed The table 500 is rotatably connected, and one end of the robot arm 300 is fixedly connected to the side of the rotating table 400 away from the fixed table 500, and the other end clamps the nozzle assembly 200 and the cooling cycle assembly 100. The delivery channel of the 3D printing material is not connected to the robot arm 300, One end is fixedly connected to the nozzle assembly 200, and the other end is directly externally connected to the feeding device. The connection of the conveying channel of the 3D printing material is a conventional design in the prior art, and will not be elaborated in the present invention.

[0045] The nozzle assembly 200 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com