Girth welding method for wind power tower tube

A wind power tower and girth welding technology, which is applied in the direction of cleaning methods using gas flow, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of large influence of external force, different welding quality of weld seam, single welding method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in detail below. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

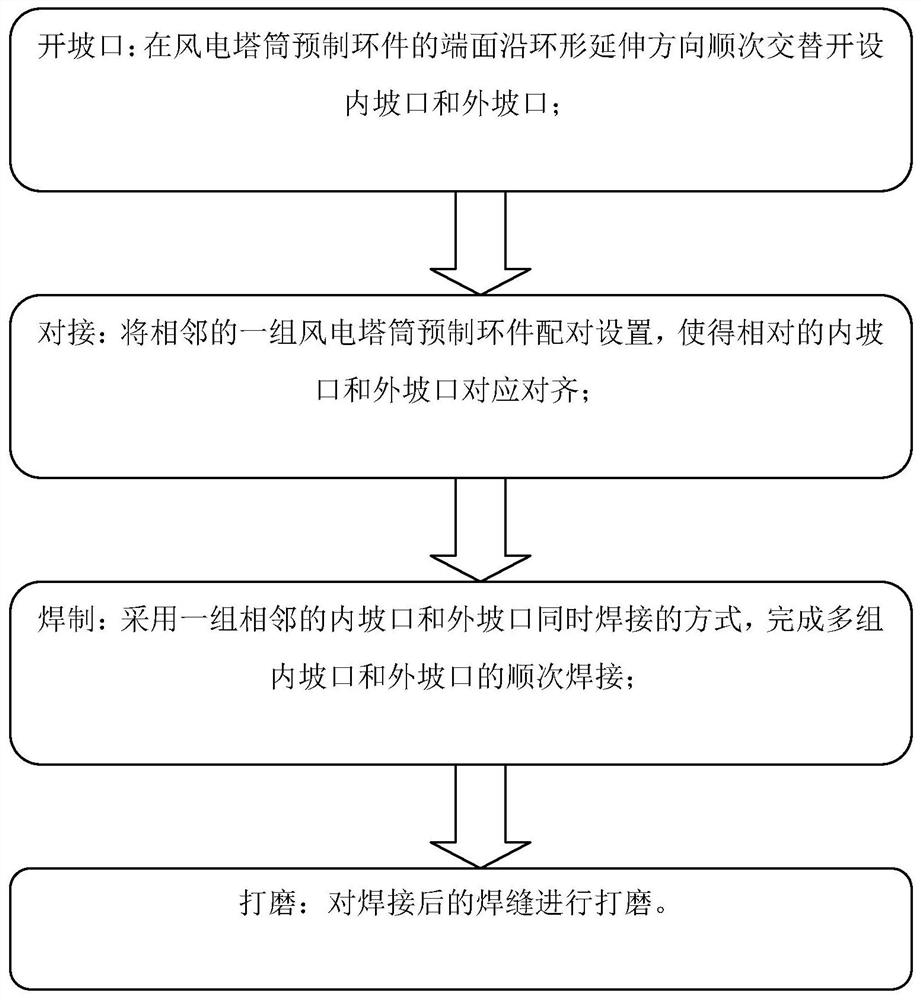

[0027] Such as figure 1 As shown, the present invention provides a kind of ring welding method of wind power tower, comprising:

[0028] 1) Beveling: on the end face of the prefabricated ring of the wind power tower, the inner groove and the outer groove are alternately opened in sequence along the direction of the circular extension;

[0029] 2) Butt joint: pair and arrange a group of adjacent prefabricated rings of wind power towers so that the opposite inner grooves and outer grooves are correspondingly aligned;

[0030] 3) Welding: A group of adjacent inner grooves and outer grooves are welded at the same time to complete the sequential welding of multiple groups of inner grooves and outer grooves;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com