Method for producing lens to be fitted to eye, and lens to be fitted to eye

A manufacturing method and lens technology, applied in the directions of glasses/protective glasses, glasses/goggles, application, etc., can solve the problems of high oxygen permeability, easy drying of eyes, easy to take away moisture from eyeballs, etc., and achieve low-cost manufacturing, simple and convenient the effect of making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0161] Hereinafter, examples of the present invention will be described. However, the present invention is not limited to the following examples.

[0162] [Reference Example A]

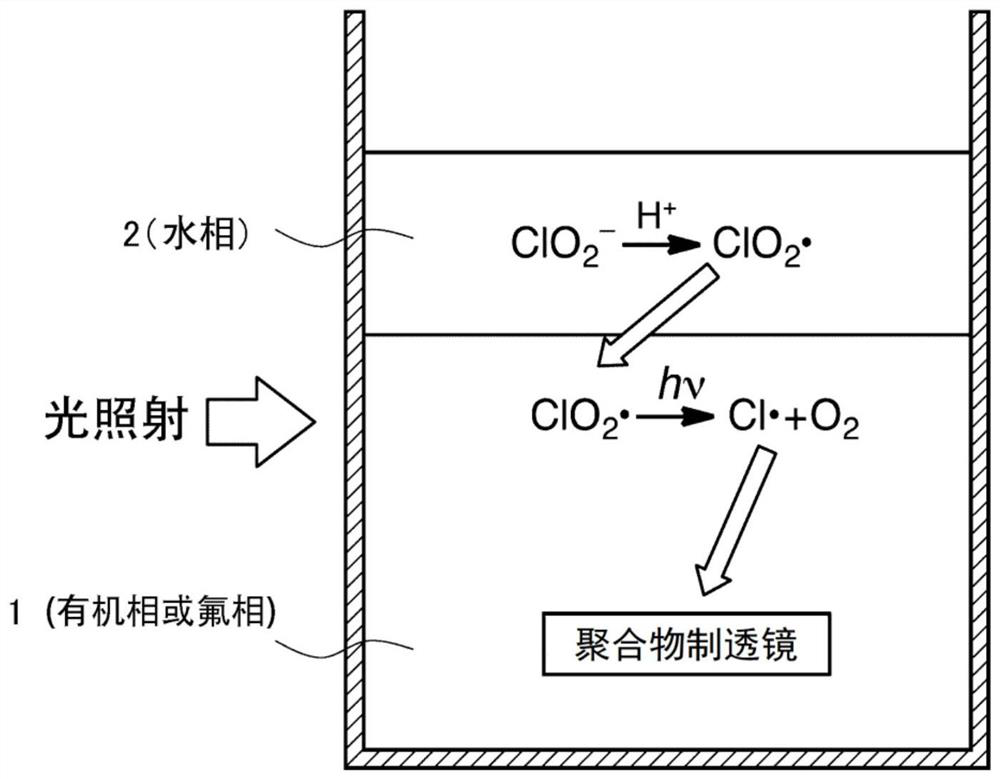

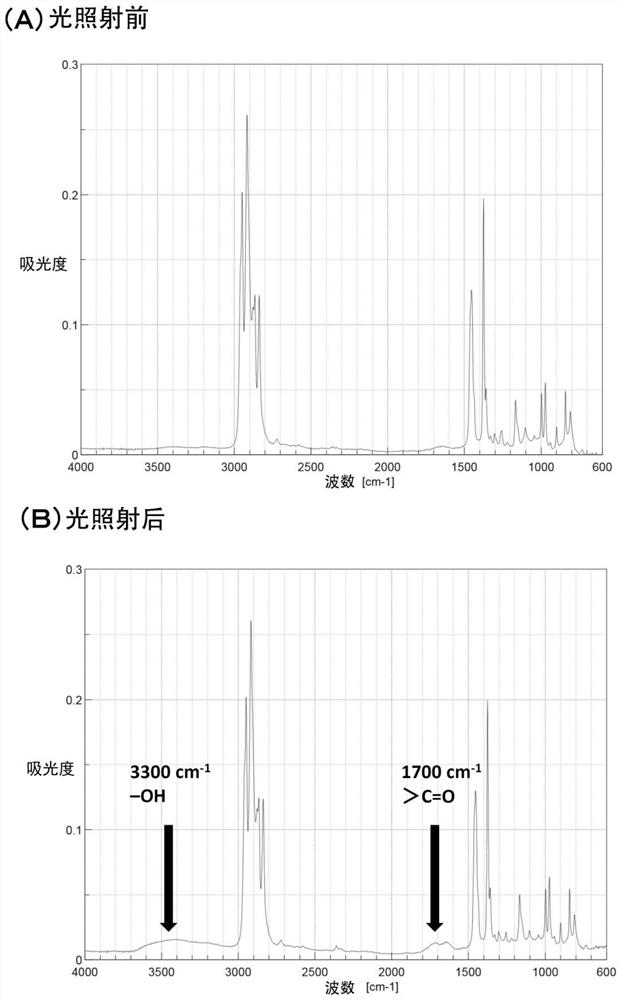

[0163] As Reference Example A, modification treatment using a liquid reaction system (hydrophilization treatment step) was performed.

reference example A1

[0165] As the organic phase, a fluorosolvent (CF 3 (CF 2 ) 4 CF 3 ). On the other hand, sodium chlorite (NaClO), which is the source of the above-mentioned carbon dioxide free radicals, 2 ) and acid ie HCl dissolved in aqueous solvent (H 2 O), prepare the aqueous phase. In the above aqueous phase, the final concentration of sodium chlorite is 500mmol / L, and the final concentration of HCl is 500mmol / L. 2 mL of the above-mentioned aqueous phase and 5 mL of the above-mentioned organic phase were put into the same reaction vessel and brought into contact with each other to prepare a two-phase reaction system. In the above-mentioned two-phase reaction system, the organic phase of the above-mentioned fluorine solvent is the lower layer, and the above-mentioned aqueous phase is the upper layer. In addition, a polypropylene film was put into the above-mentioned reaction container. The above-mentioned film is in a state of sinking into the organic phase of the above-mentioned l...

reference example B1

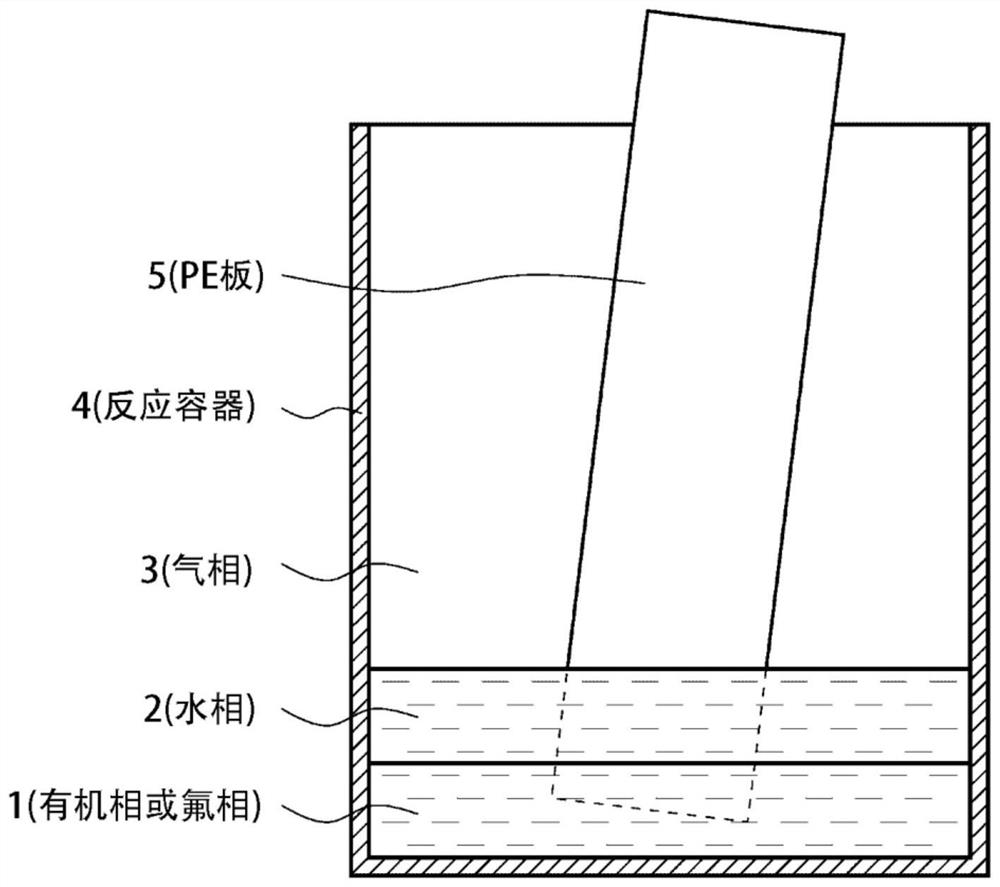

[0171] Fluorinated solvent (CF 3 (CF 2 ) 4 CF 3 ) 4mL, water (H 2 O) 2mL, sodium chlorite (NaClO 2 ) 90 mg and 20 μL of 35% hydrochloric acid (HCl) were added to the same reaction vessel and stirred for 5 minutes. The above-mentioned reaction vessel was left to stand, and separated into an organic phase, an aqueous phase, and a gas phase of the fluorine solvent from bottom to top. In addition, it was confirmed that the above-mentioned organic phase was yellow, and that white gas was generated in the above-mentioned gas phase. Chlorine dioxide radicals are generated in the above-mentioned aqueous phase and dissolved in the more stable above-mentioned organic phase (fluorinated solvent). That is, the yellow change of the above-mentioned organic phase means the generation of chlorine dioxide radicals, so in this reference example, the generation of chlorine dioxide radicals was confirmed. In addition, if chlorine dioxide radicals are dissolved in the above-mentioned organi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com