Tool and method for preventing bare electric core from shifting during soft package packaging

A bare cell and soft package technology, applied in the field of tooling to prevent the displacement of the bare cell during soft package packaging, can solve problems such as breakage of the tab, hollowing of the cell, affecting the heat conduction of the cell, etc. The effect of preventing position shift and applying a wide range of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

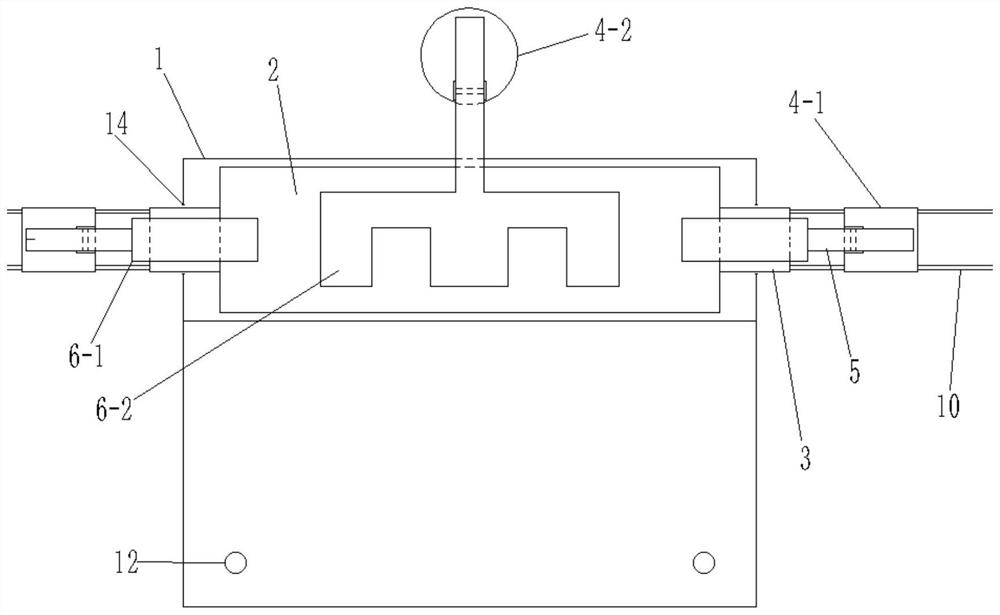

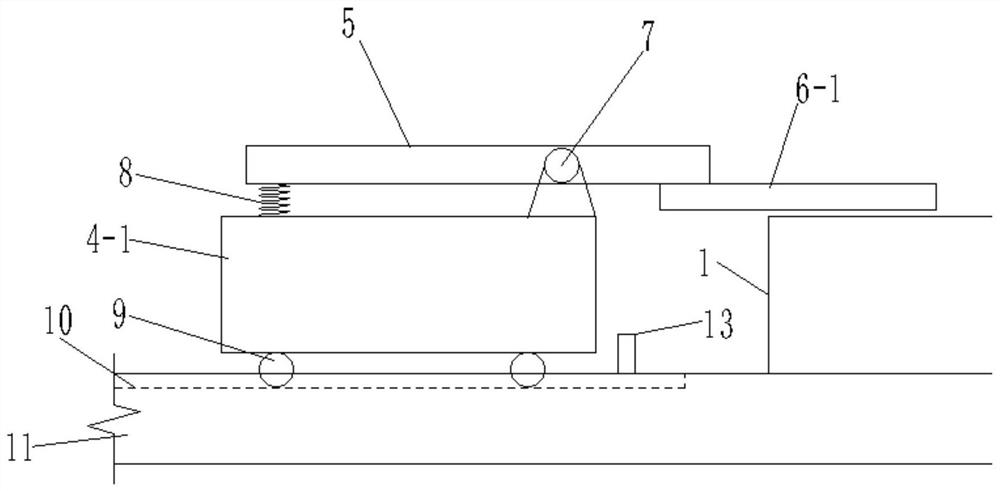

[0026] exist figure 1 and figure 2 In the shown embodiment, a tooling of the present invention that prevents bare cells from shifting when packaged in a soft package includes a limit groove 1, a lug pressure plate 6-1, a cell pressure plate 6-2, a pin 12, a pressure plate Rod 5, bracket 7, base 4-1 of the lug pressure plate, base 4-2 of the cell pressure plate and the bottom plate 11, both ends of the limit groove are provided with lug slots 14 for fixing the lugs, The lug pressure plate with a rectangular cross section is set on the end of the pressure rod close to the bare cell 2, and is fixedly connected to the pressure rod. The middle part of the pressure rod is hinged to the bracket. The bracket consists of two lugs and a connecting shaft, as figure 2 As shown, two-thirds of the pressure rod is provided with a through hole through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com