Aviation fuel sampler and sampling method

A technology of aviation fuel and sampler, which is applied in the field of aircraft inspection, can solve the problems of easy generation of impurities, surface damage of airborne finished products, cost waste, etc., and achieve the effects of easy disassembly, improved reliability, and avoiding fuel waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

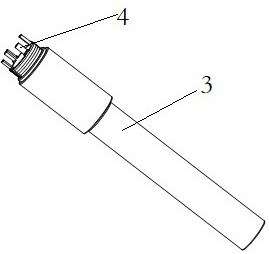

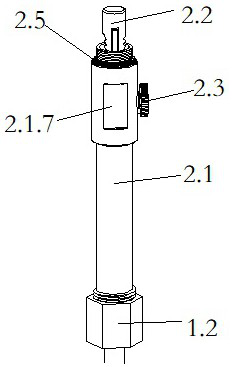

[0046] This embodiment discloses a kind of aviation fuel sampler, as a kind of basic embodiment of the present invention, comprises oil guide unit 1 and sampling main body 2; Oil guide unit 1 comprises oil guide hose 1.1, one end of oil guide hose 1.1 A quick-release movable nut 1.2 is provided, the other end of the oil guide hose 1.1 is provided with an oil nozzle 1.3, and a throttle valve 1.4 is arranged on the oil outlet nozzle 1.3; the sampling body 2 includes a hollow cylindrical shell 2.1 with two ends open, a hollow It is the shell chamber 2.1.1 of the shell 2.1, and the shell cavity 2.1.1 is provided with a door-opening inner column 2.2; the shell 2.1 is provided with a rotation mechanism that controls the door-opening inner column 2.2 to move back and forth along the axial direction of the shell 2.1 through its own rotation. The adjustment mechanism 2.3, the rotation adjustment mechanism 2.3 cooperates with the door-opening inner column 2.2, and is used to push open th...

Embodiment 2

[0049] This embodiment discloses an aviation fuel sampler, as a preferred embodiment of the present invention, that is, in embodiment 1, the housing 2.1 is provided with an assembly hole 2.1.4 for installing the rotation adjustment mechanism 2.3, and the rotation adjustment mechanism 2.3 passes through the assembly hole 2.1.4, and is flexibly connected with the door-opening inner column 2.2; the assembly hole 2.1.4 is provided with a bushing 2.4, and the rotation adjustment mechanism 2.3 is flexibly connected with the casing 2.1 through the bushing 2.4; the casing 2.1 The ring body boss 2.1.6 is arranged in the circumferential direction, and the two sides of the ring body boss 2.1.6 are provided with a stressed concave surface 2.1.7; the assembly hole 2.1.4 is arranged on the ring body boss 2.1.6; the shell 2.1 The end connected to the oil discharge port of the aircraft body is provided with a sealing rubber ring I2.5 for elastic sealing with the oil discharge port of the aircr...

Embodiment 3

[0052] This embodiment discloses an aviation fuel sampler, as a preferred embodiment of the present invention, that is, in embodiment 2, the rotation adjustment mechanism 2.3 includes a handwheel disc 2.3.1 and a gear column 2.3.2, and the handwheel disc 2.3 .1 The bottom is provided with a smooth cylinder 2.3.3 for sealing fit with the bushing 2.4, the gear column 2.3.2 is fixedly connected with the hand wheel 2.3.1 through the smooth cylinder 2.3.3; In the space groove 2.2.1 for accommodating the gear column 2.3.2, at least one side wall of the space groove 2.2.1 is provided with a rack structure 2.2.2 for cooperating with the gear column 2.3.2; the bottom of the handwheel disc 2.3.1 A stop pin 2.3.4 is provided to prevent the rotation adjustment mechanism 2.3 from automatically rotating, and the housing 2.1 is provided with a latch groove 2.1.5 for cooperating with the stop pin 2.3.4; the shell cavity 2.1.1 is provided with a guide slide Slot 2.1.8, the side of the door-ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com