High-medium-pressure dummy-shaft-free final assembly method for modified unit

An assembly method, high and medium pressure technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of delay time, high and medium pressure inner cylinder and inner sleeve assembly cycle, low work efficiency, etc., to meet the maintenance period. , Save assembly time and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

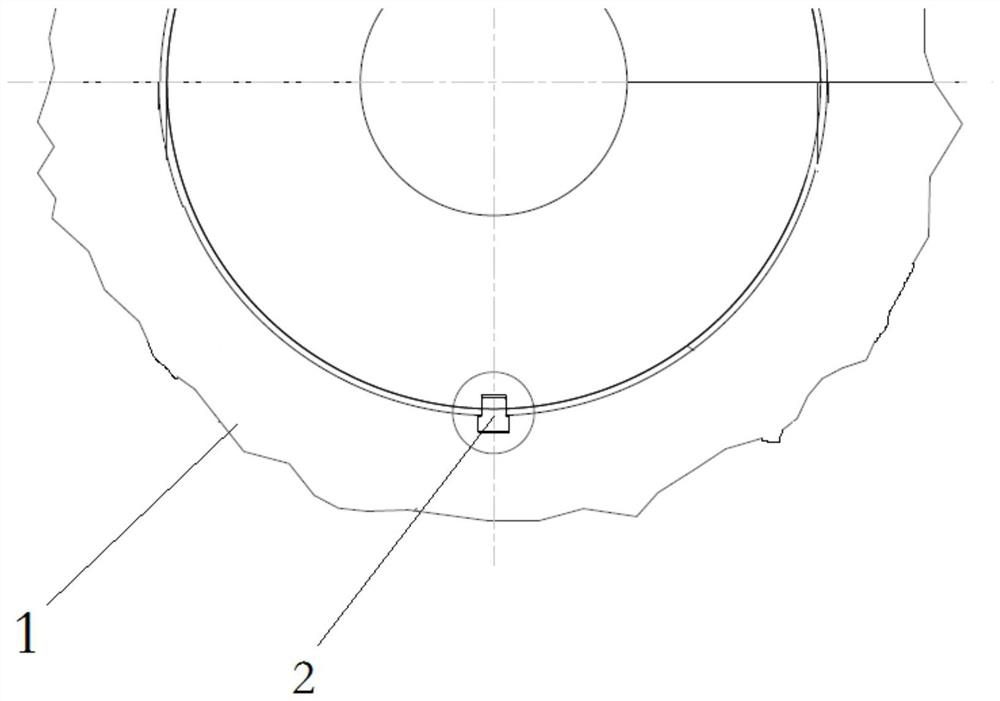

[0022] Specific implementation mode one: combine figure 1 To illustrate this embodiment, a method for assembly of a transformation unit with high and medium pressure without a false shaft described in this embodiment, the specific assembly method is as follows:

[0023] Step 1. Prepare a suitable assembly site, arrange the foundation cushion box and plane jacks, and the jacks are evenly arranged. Put the lower half of the high and medium pressure inner cylinder on the cushion box, set up a leveling ruler, and adjust the level of the lower half of the inner cylinder by adjusting the jack. The vertical and horizontal levels of the high and medium pressure inner cylinder are zero. After the level adjustment is qualified, use the pressure plate to press the inner cylinder and the cushion box firmly at the joint between the inner cylinder and the outer cylinder;

[0024] Step 2. Check the high and medium pressure inner cylinder and the back arc measurement positions of the inner sl...

specific Embodiment approach 2

[0035] Specific implementation mode two: combination figure 1 Describe this embodiment. This embodiment is a further limitation on the assembly method described in Embodiment 1. In this embodiment, an assembly method for remodeling a unit with high and medium pressure without a false shaft is described. The appearance quality requirements of the inner cylinder and each inner sleeve back arc measurement position must be free from "seven evils", and the steam seal teeth should not be knocked, damaged, or crooked, and should be corrected if any;

[0036] In this specific implementation mode, the appearance quality requirements of the measurement positions of the middle, high and medium pressure inner cylinders and the back arcs of each inner sleeve in the above-mentioned step 2 are free from "seven evils", and the steam seal teeth are free from bumps, damages, and crookedness. Ensure the appearance quality of the high and medium pressure inner cylinder and the back arc measuremen...

specific Embodiment approach 3

[0037] Specific implementation mode three: combination figure 1 Describe this embodiment. This embodiment is a further limitation on the assembly method described in the second specific embodiment. In this embodiment, a method for the assembly of a modified unit with high and medium pressure without a false shaft, the measurement in the second step The specific method of the back arc clearance is as follows: the size of the upper and lower radial pin grooves of the inner sleeve, the size of the upper and lower half pin holes of the high-pressure inner cylinder, make a record of the size, and install the process radial pin in the lower half of the high-pressure inner cylinder, and carry out according to the drawing For installation, use a square to check that the radial pins are not deflected;

[0038] In this specific embodiment, a square is used to check that the radial pins are not deflected, thereby improving the probability of successful assembly and avoiding wear and tear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com