Textile yarn dedusting and sizing device

A technology for spinning yarns and yarns is applied in the fields of yarn processing equipment and textile yarn dust removal and sizing devices, which can solve the problems of incomplete sizing, difficult to clean up, and static electricity, so as to improve the cleanliness and the sizing effect. , the effect of improving textile performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

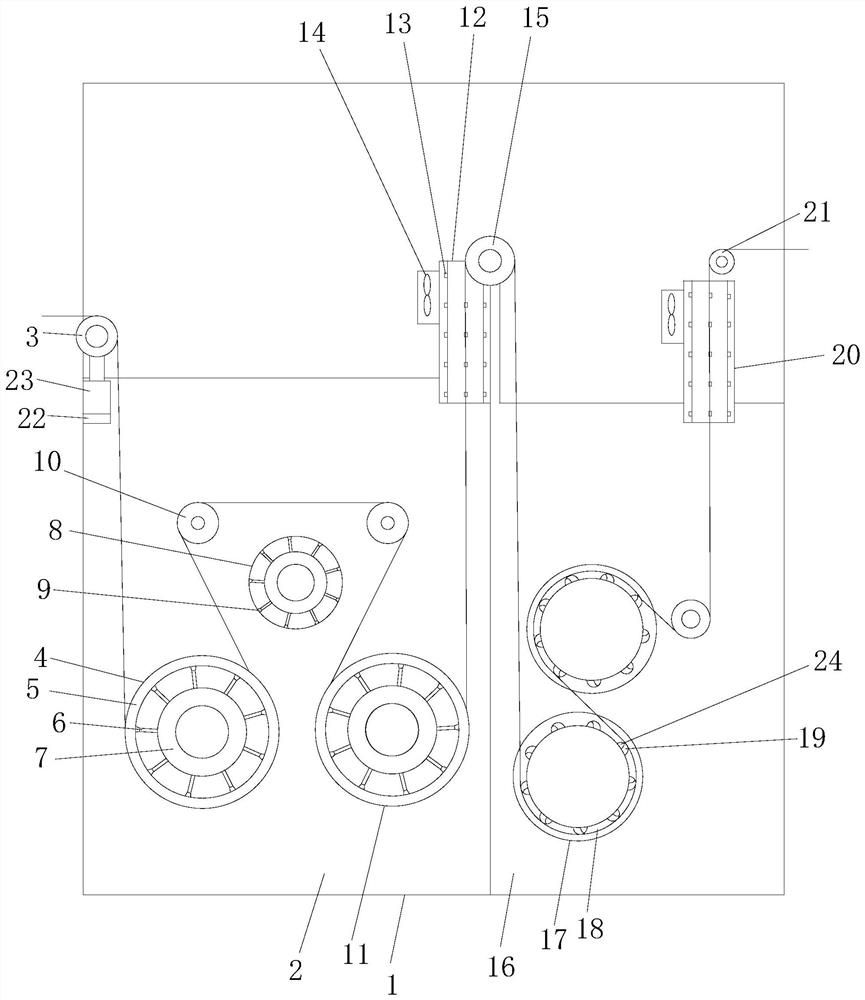

[0014] refer to figure 1 , a textile yarn dedusting and sizing device of the present invention, comprising a frame 1, a cleaning box 2, a wire feed wheel 3, a first cleaning roller 4, a yarn guide ring groove 5, a water spray hole 6, a water spray pump 7, a first Second cleaning roller 8, cleaning nozzle 9, auxiliary yarn guide wheel 10, third cleaning roller 11, first hot air drying channel 12, hot air spray hole 13, hot air blower 14, yarn transition wheel 15, sizing tank 16, first Sizing wheel 17, yarn sizing ring groove 18, stirring paddle 19, second hot air drying channel 20 and discharge guide wheel 21, a cleaning box 2 is arranged on the left side of the frame 1, and the cleaning box 2 The left top of the left side is provided with a wire feed wheel 3, the first cleaning roller 4 is provided under the right side of the wire feed wheel 3, and the circumferential surface of the first cleaning roller 4 is provided with a yarn guide ring groove 5, The bottom surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com