Antibacterial medical suture line and preparation method

A suture and ascorbic acid technology, applied in the field of antibacterial medical suture and preparation, can solve the problems of use limitation, insufficient flexibility, etc., and achieve the effects of less reduction, good water immersion resistance, and good antibacterial durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of L-ascorbate,

[0045] Preparation of 5,6-O-isopropylidene-L-ascorbic acid: Mix L-ascorbic acid, acetone, and phosphorus oxychloride, and react at 25°C for 5 hours. Washed with water and dried in vacuo to give 5,6-O-isopropylidene-L-ascorbic acid. The addition amount of L-ascorbic acid was 20 wt % of acetone, and the addition amount of phosphorus oxychloride was 5 wt % of acetone.

[0046] Preparation of 3,4-dihydroxyphenylpropionyl chloride: Mix 3,4-dihydroxyphenylpropionic acid and thionyl chloride, react at 50°C for 4h, and concentrate under reduced pressure to remove unreacted Thionyl chloride gives 3,4-dihydroxyphenylpropionyl chloride. The amount of 3,4-dihydroxyphenylpropionic acid added was 10% by weight of thionyl chloride.

[0047] The molecular formula of 3,4-dihydroxyphenylpropionyl chloride is as follows:

[0048]

[0049] In the detection of 3,4-dihydroxyphenylpropionyl chloride by 1H NMR, deuterated acetone was used as solven...

Embodiment 2

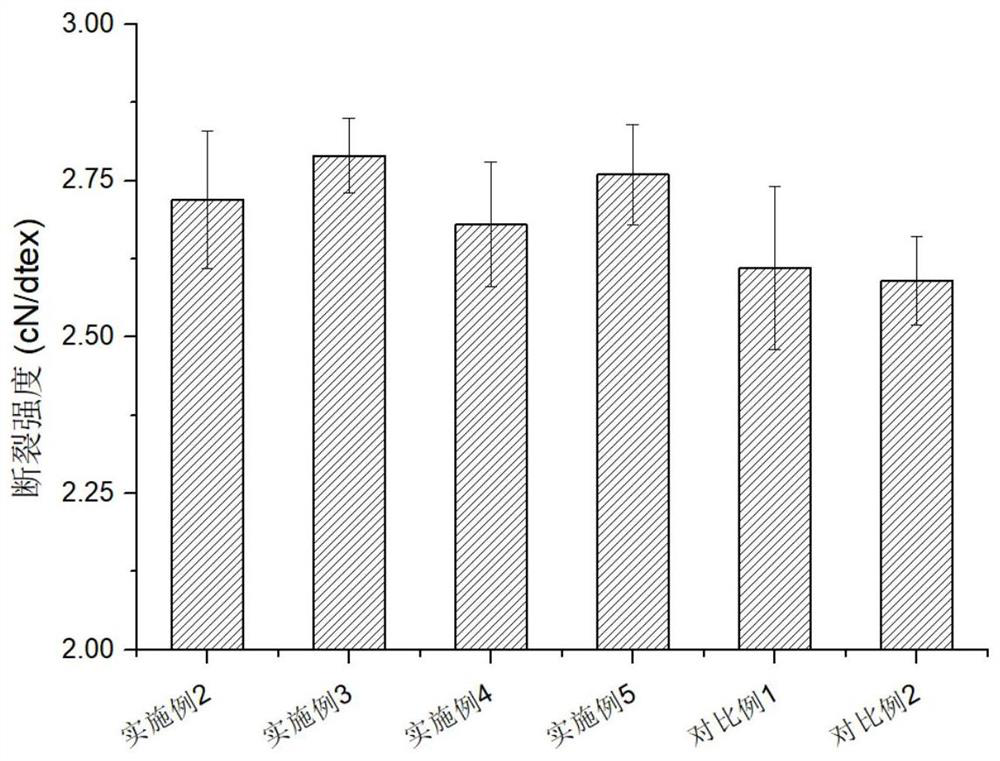

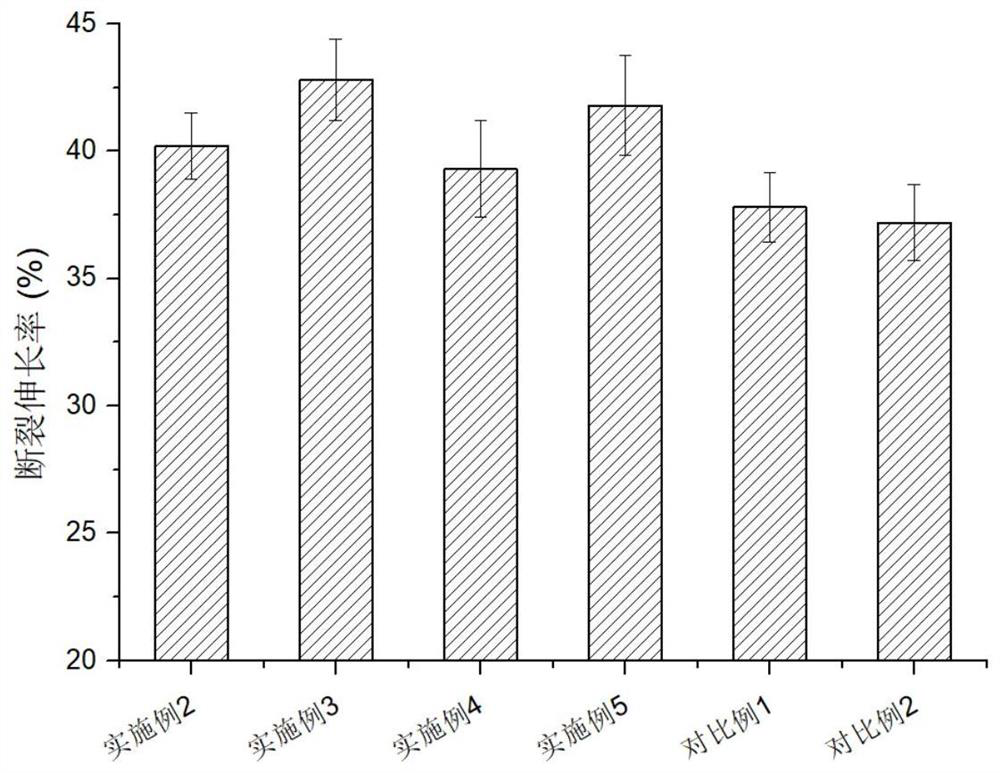

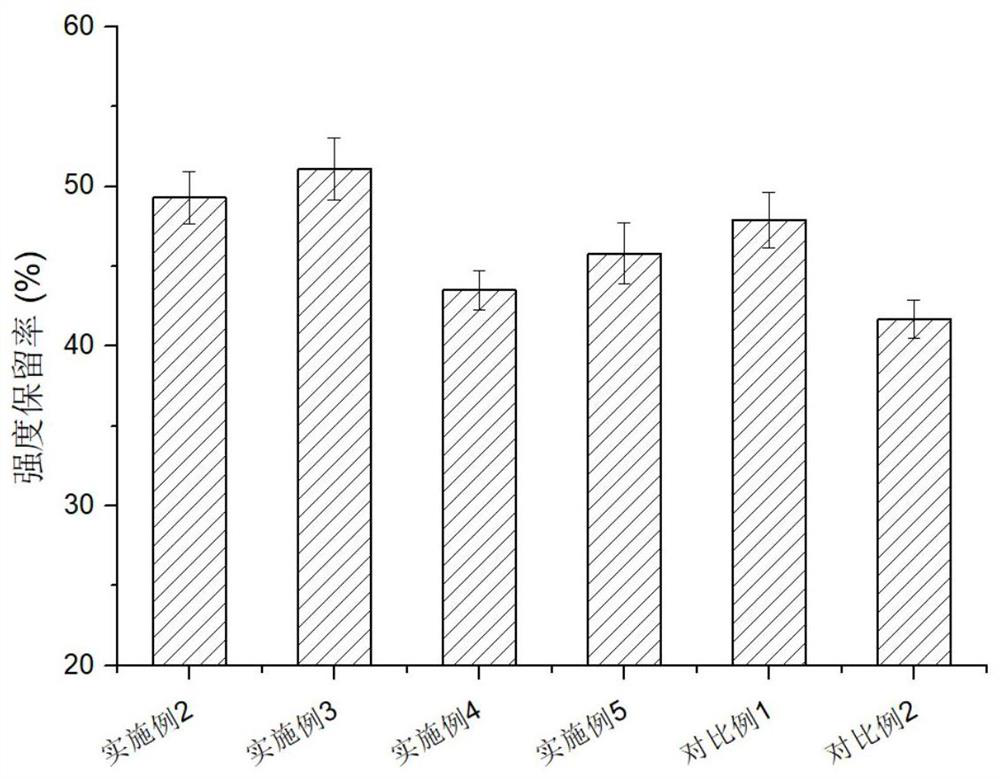

[0056] A preparation method of antibacterial medical suture,

[0057] Preparation of skin layer (PLA) particles: Mix hydroxypropyl cellulose, L-ascorbic acid ester obtained in Example 1, PLA, and glutaraldehyde evenly, and blend them on an internal mixer at a temperature of 170 ° C for 10 minutes. After pulverization, the blend particles were obtained by vacuum drying. The amount of L-ascorbate added was 8 wt% of PLA. The amount of hydroxypropyl cellulose added was 8 wt % of PLA. The amount of glutaraldehyde added was 2 wt% of PLA.

[0058] Preparation of composite fiber: Put the skin layer (PLA) particles and the core layer material into the skin layer barrel and the core layer barrel respectively, heat to 175 ℃ to melt, defoaming, spin through a nozzle with a diameter of 1mm to obtain virgin silk, which is obtained by cooling with an aqueous solution The spun silk, the spun silk is respectively drawn once and twice at a temperature of 70°C to obtain a composite fiber. Th...

Embodiment 3

[0061] A preparation method of antibacterial medical suture,

[0062] Preparation of skin layer (PLA) particles: Mix hydroxypropyl cellulose, L-ascorbic acid ester obtained in Example 1, PLA, and glutaraldehyde evenly, and blend them on an internal mixer at a temperature of 170 ° C for 10 minutes. After pulverization, the blend particles were obtained by vacuum drying. The amount of L-ascorbate added was 16 wt% of PLA. The amount of hydroxypropyl cellulose added was 8 wt % of PLA. The amount of glutaraldehyde added was 2 wt% of PLA.

[0063] Preparation of composite fiber: Put the skin layer (PLA) particles and the core layer material into the skin layer barrel and the core layer barrel respectively, heat to 175 ℃ to melt, defoaming, spin through a nozzle with a diameter of 1mm to obtain virgin silk, which is obtained by cooling with an aqueous solution The spun silk, the spun silk is respectively drawn once and twice at a temperature of 70°C to obtain a composite fiber. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com