Debris cleaning device for numerical control machine tool

A cleaning device, a technology of CNC machine tools, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of affecting the machine tool, reducing the cleaning effect of debris, inability to coexist and linkage, etc., to achieve smooth operation, Easy to clean and easy to discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

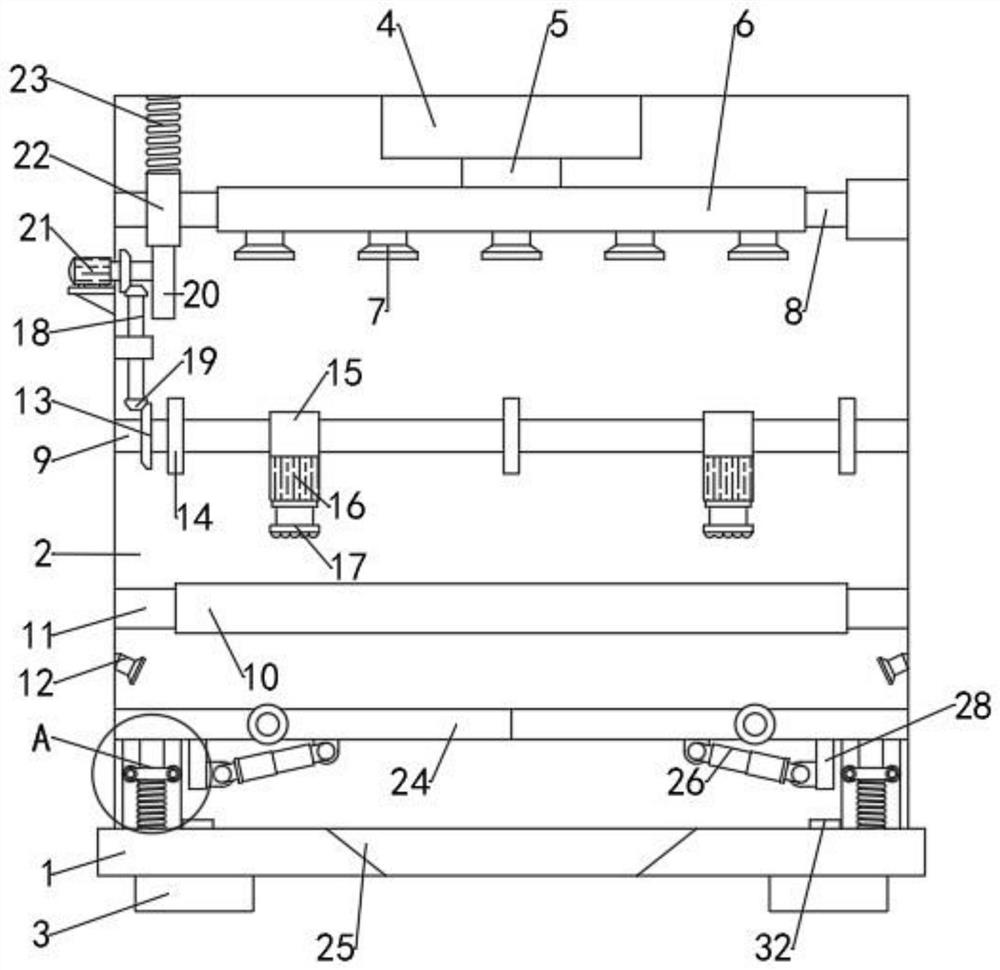

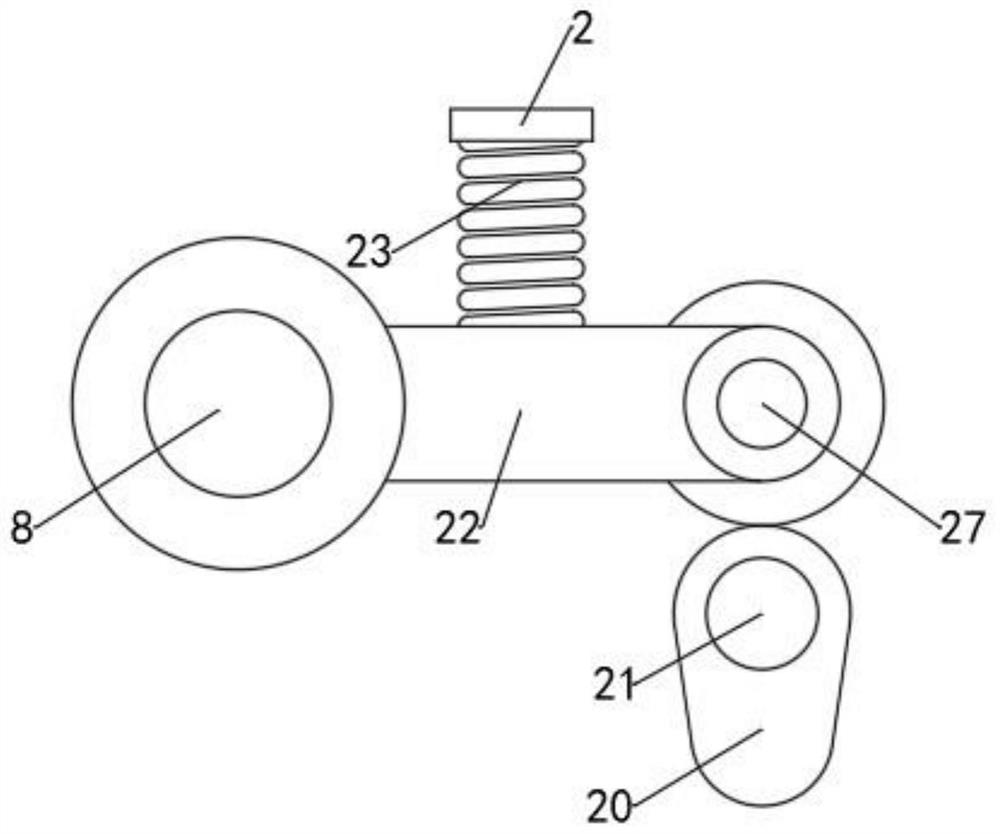

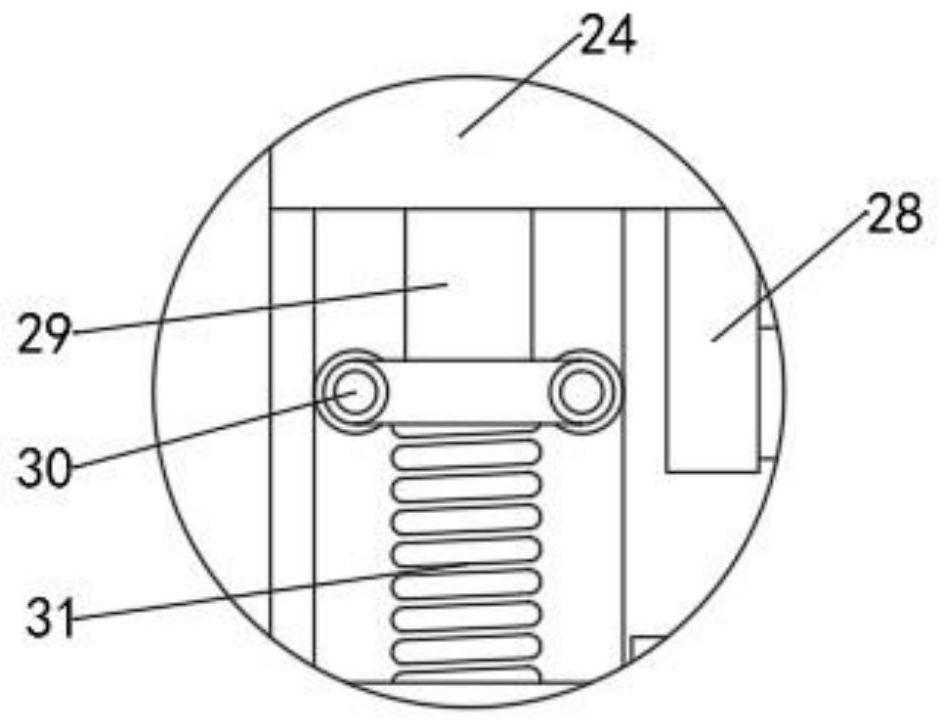

[0020] see Figure 1-4 , a debris cleaning device for numerical control machine tools, including a base 1, a cavity 2 is fixed on the upper end of the base 1, a workbench 10 is arranged on the inside of the cavity 2, and the two sides of the workbench 10 pass through several Evenly distributed connection bases 11 are connected to the cavity 2, and interlocking cleaning mechanisms and blowing mechanisms are arranged on the top of the workbench 10 to ensure the cleaning effect of debris; the blowing mechanisms include the first blower 4, the second A blower 4 is installed on the inner upper part of the cavity 2, the lower end of the first blower 4 communicates with the first substrate 6 via the delivery pipe 5, and the lower end of the first substrate 6 is evenly arranged with some air outlet pipes 7, and the first substrate 6 Both sides are installed and connected with the cavity 2 via the rotating shaft 8, wherein the rotating shaft 8 on one side is fixedly connected with a tr...

Embodiment 2

[0029] In order to facilitate the replacement of the cleaning brush 17 and ensure the cleaning effect, this embodiment is improved on the basis of Embodiment 1. The improvement is: the cleaning brush 17 is connected to the shaft of the cleaning motor 16 by a mating screw thread. In order to facilitate the disassembly and replacement of the cleaning brush 17, it is convenient to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com