Desk type circular saw with upper table

A workbench and circular saw technology, which is applied to circular saws, sawing equipment, sawing machine devices, etc., can solve problems such as flying workers, suction tubes affecting work, and affecting the smooth operation of desktop circular saws, so as to improve operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

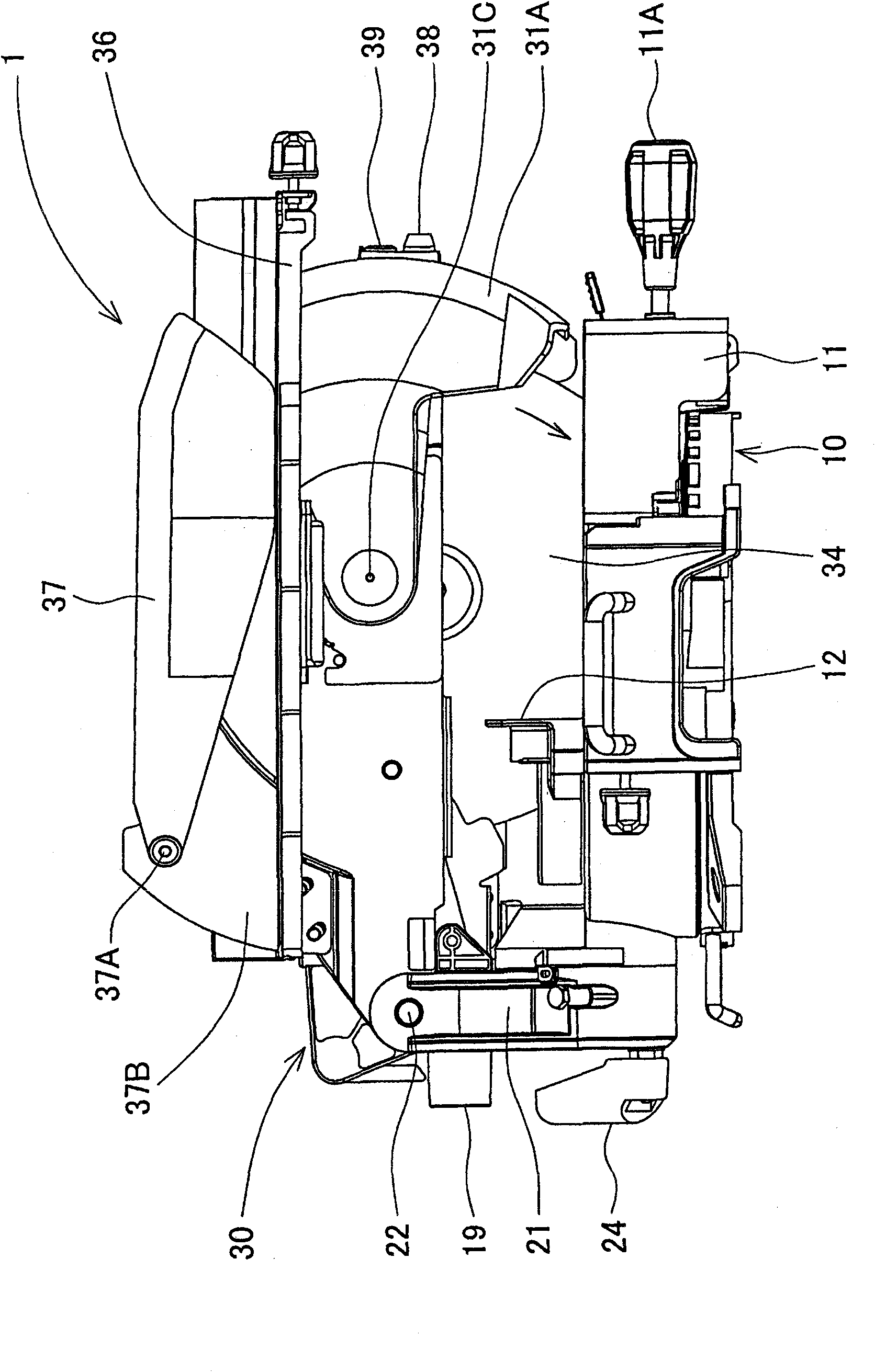

[0033] Refer to attached Figure 1~5 , the embodiment of the present invention will be described. As shown in the figure, the desktop circular saw with an upper workbench includes: a base 10 ; a body supporting part 20 ; and a circular saw body 30 .

[0034] The base 10 includes: a rotating table 11 and a baffle 12 . The upper surface of the rotary table 11 is used to place, for example, timber waiting to be cut. A handle 11A is provided in front of the turntable 11 . The operator can move the turntable 11 horizontally by holding the handle 11A to operate it, and can fix it after turning the turntable 11 by a predetermined angle in the horizontal direction. A baffle 12 is disposed above the base 10 . The purpose of the baffle 12 is to position it in contact with the wood.

[0035] Such as Figure 4 As shown, on the upper surface of the rotary table 11, a left knife edge plate 14A and a right knife edge plate 14B are installed at a certain interval. A gap 15 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com