Preparation method of polytetrafluoroethylene reverse osmosis membrane with lasting and stable filtering separation performance

A polytetrafluoroethylene-based membrane and polytetrafluoroethylene technology, applied in the field of reverse osmosis, can solve problems such as the surface peeling of a porous support layer, and achieve the effects of improving lasting stability, prolonging service life, and increasing binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

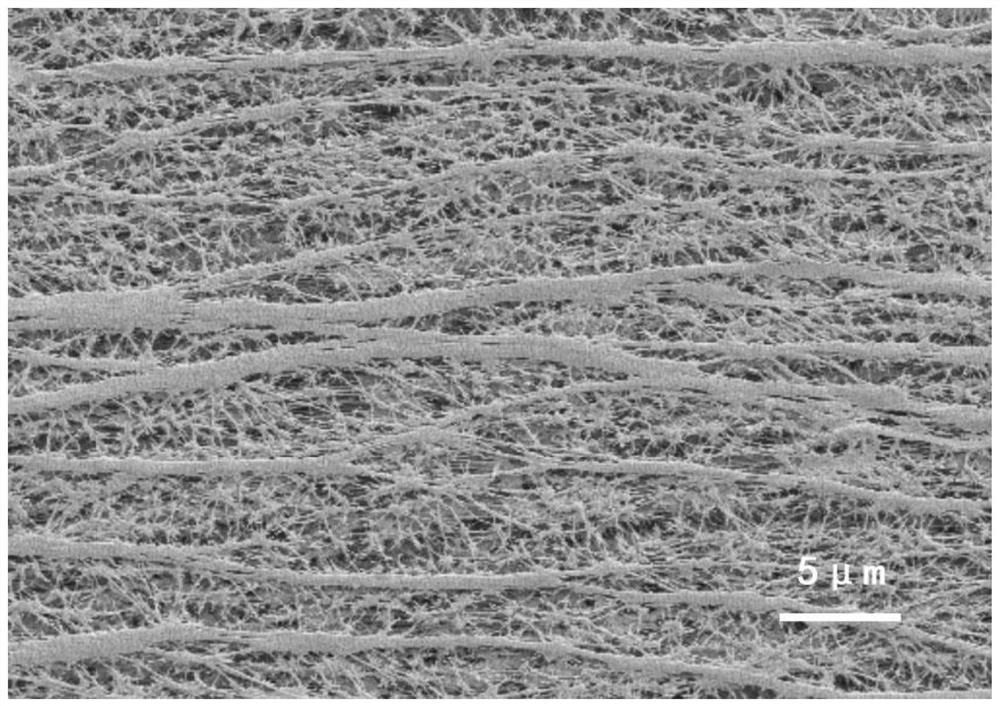

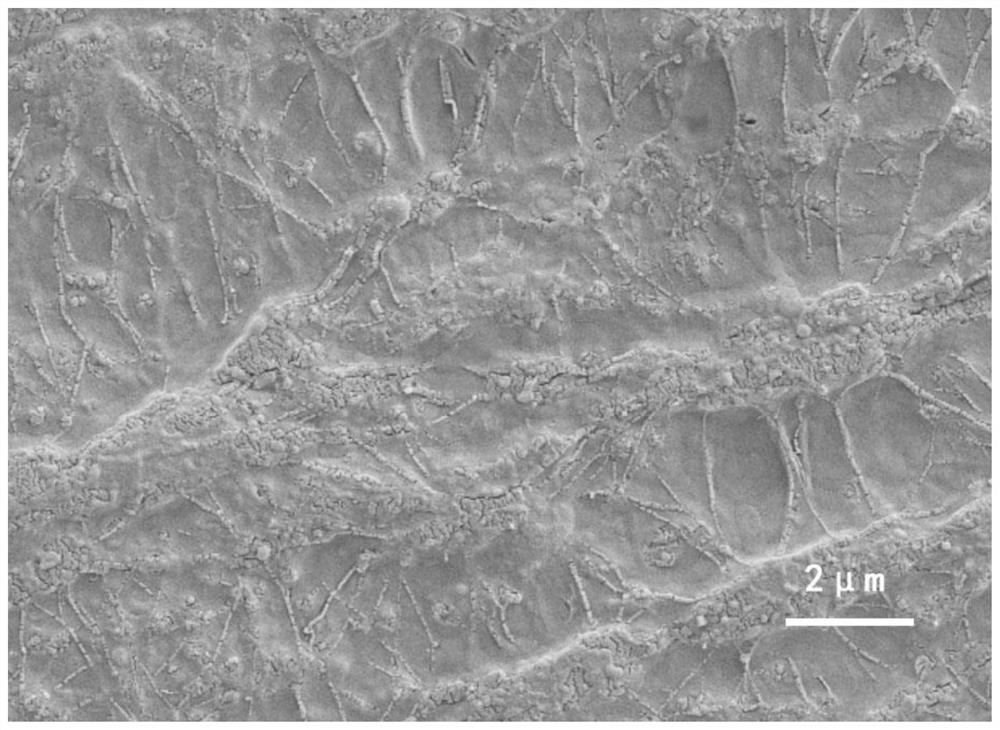

Image

Examples

Embodiment 1

[0027] A method for preparing a polytetrafluoroethylene reverse osmosis membrane with long-lasting and stable filtration and separation performance, comprising the following steps:

[0028] (1) Carboxymethyl chitosan was added into deionized water and stirred and dissolved to prepare a carboxymethyl chitosan solution with a mass concentration of 3%, and absolute ethanol and carboxymethyl chitosan solution were mixed according to the volume ratio of 1:1 The proportion of mixture was mixed to obtain a mixed solution, and the polytetrafluoroethylene-based film was immersed in the mixed solution, soaked for 8 hours, taken out and placed in an oven at 50 ° C for 30 minutes to dry to obtain a polytetrafluoroethylene-based film a;

[0029] (2) Tetraethyl orthosilicate is added in absolute ethanol according to the volume ratio of 1:20, and stirred and mixed evenly to obtain a tetraethyl orthosilicate solution, which is set aside; ammonia water (mass concentration 25-28%), Water ethano...

Embodiment 2

[0034] A method for preparing a polytetrafluoroethylene reverse osmosis membrane with long-lasting and stable filtration and separation performance, comprising the following steps:

[0035] (1) Carboxymethyl chitosan was added into deionized water and stirred and dissolved to prepare a carboxymethyl chitosan solution with a mass concentration of 2%, and absolute ethanol and carboxymethyl chitosan solution were mixed in a volume ratio of 1:0.5 The proportion of mixture was mixed to obtain a mixed solution, the polytetrafluoroethylene-based film was immersed in the mixed solution, soaked for 7 hours, taken out and placed in an oven for 30 minutes at 50 ° C to dry to obtain a polytetrafluoroethylene-based film a;

[0036] (2) Tetraethyl orthosilicate is added in absolute ethanol according to the volume ratio of 1:20, and stirred and mixed evenly to obtain a tetraethyl orthosilicate solution, which is set aside; ammonia water (mass concentration 25-28%), Water ethanol and deionize...

Embodiment 3

[0041] A method for preparing a polytetrafluoroethylene reverse osmosis membrane with long-lasting and stable filtration and separation performance, comprising the following steps:

[0042] (1) Carboxymethyl chitosan was added into deionized water and stirred and dissolved to prepare a carboxymethyl chitosan solution with a mass concentration of 5%, and absolute ethanol and carboxymethyl chitosan solution were mixed in a volume ratio of 1:0.8 The mixture was mixed to obtain a mixed solution, and the polytetrafluoroethylene-based film was immersed in the mixed solution for 10 hours. After taking it out, it was placed in an oven and dried at 50°C for 30 minutes to obtain a polytetrafluoroethylene-based film a;

[0043] (2) Tetraethyl orthosilicate is added in absolute ethanol according to the volume ratio of 1:20, and stirred and mixed evenly to obtain a tetraethyl orthosilicate solution, which is set aside; ammonia water (mass concentration 25-28%), Water ethanol and deionized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com