Nutritional flavored composite sauce and preparation method thereof

A technology of flavor and nutrition, which is applied in the field of nutrition-flavor compound sauce and its preparation, can solve the problems of insufficient natural environmental protection, destruction of nutrients, and greasy feeling, and achieve the effects of retaining nutritional value, easy digestion and absorption, and extending shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

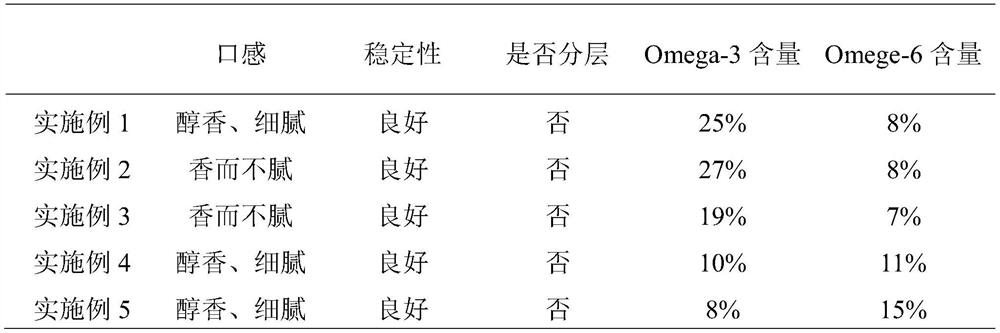

Examples

Embodiment 1

[0042] A preparation method of nutritious flavor compound sauce, said method comprises the following steps,

[0043] S1 material pretreatment:

[0044] S1.1 Dehull the linseed, screen (the standard is no impurities), and separate to obtain linseed and linseed bark.

[0045] S1.2 Soak an appropriate amount of flaxseed in 20% 55-type fructooligosaccharide solution ultrasonically for 60 minutes at 50°C, and the moisture content of the flaxseed is about 19%. Then, at 40KW, 95°C, microwave oven drying for 40min. Put the toasted flaxseed in a special cabinet for later use.

[0046] S1.3 The flax husk that has been taken off is screened (the standard is no foreign matter), and then ultrafinely pulverized, and then passed through an 80-mesh sieve to obtain flax husk powder, which is stored for later use.

[0047] S2 grinds the pretreated linseed to obtain sauce A.

[0048] S3 Take a certain amount of vegetable oil (mass ratio to sauce A: 1:7) and preheat it to 80°C, add flax husk ...

Embodiment 2

[0052] A preparation method of nutritious flavor compound sauce, said method comprises the following steps,

[0053] S1 material pretreatment:

[0054] S1.1 Dehull the linseed and perilla seeds respectively, and screen to obtain flax seeds and perilla seeds.

[0055] S1.2 Soak an appropriate amount of flaxseed and perilla seed in 17% 55-type fructooligosaccharide solution at 55°C for 50 minutes ultrasonically. The moisture content of both flaxseed kernel and perilla seed kernel is about 20%. Then, at 40KW, 100°C, microwave oven drying for 40min. Put the toasted linseeds and perilla seeds into a special cabinet for later use.

[0056]S1.3 The flax husk obtained in Example 1 was screened and ultrafinely pulverized, and passed through a 100-mesh sieve to obtain flax husk powder, which was stored for later use.

[0057] S2 mixes the pretreated linseed and perilla seed in a mass ratio of 3:1, and grinds the sauce to obtain the sauce A.

[0058] S3 Take a certain amount of veget...

Embodiment 3

[0062] A preparation method of nutritious flavor compound sauce, said method comprises the following steps,

[0063] S1 material pretreatment:

[0064] S1.1 Dehull the chia seeds, hemp seeds and perilla seeds, and screen to obtain the corresponding raw material kernels and raw material skins.

[0065] S1.2 Appropriate amount of the three kinds of raw material kernels were ultrasonically soaked with 15% 55-type fructo-oligosaccharide solution at 55°C for 60 minutes, and the moisture content of the raw material kernels was 21%. Then, the kernels of the three raw materials were baked and dried by microwave at 42KW, 105°C for 45min. Put the roasted raw material kernels into a special cabinet for later use.

[0066] S1.3 The chia seed skin removed in step S1.1 is screened and ultrafinely pulverized, and then passed through an 80-mesh sieve to obtain chia seed skin powder, which is mixed with the flax obtained in Example 1 Skin powder is mixed evenly according to the mass ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com