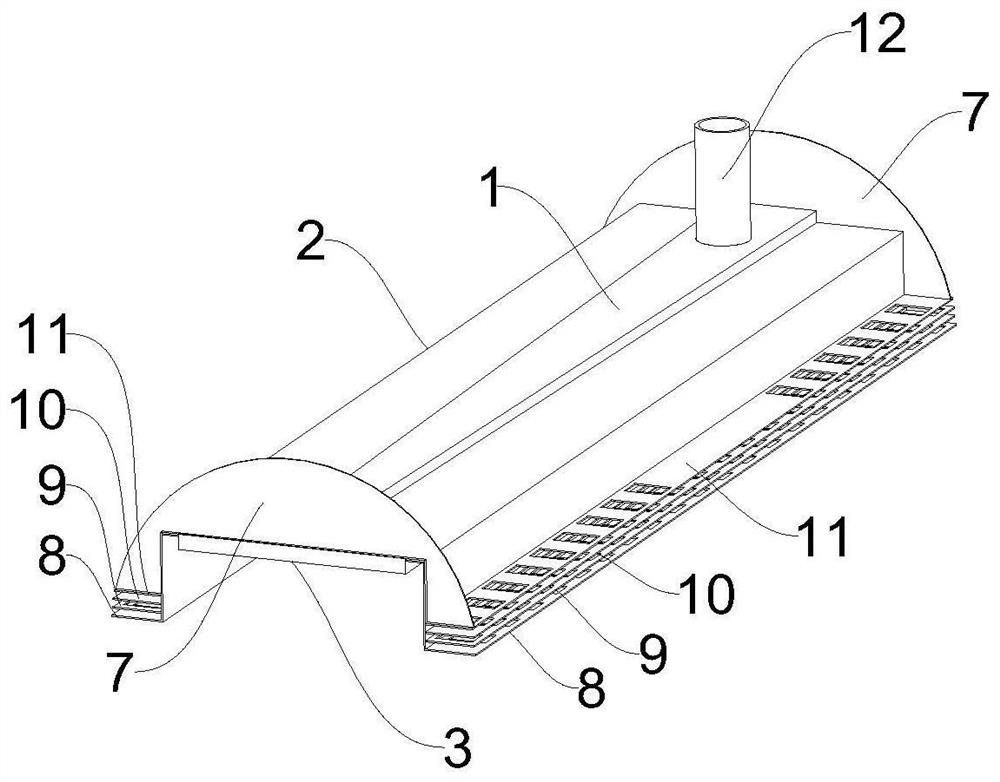

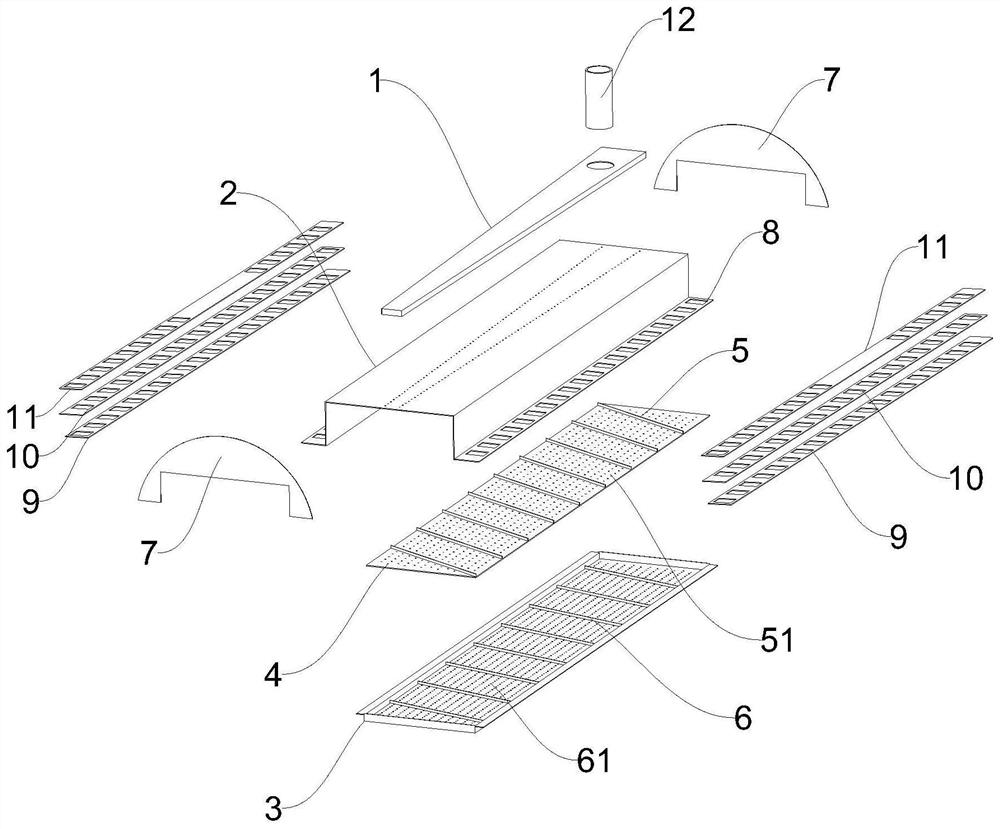

Liquid homogenizing device and air conditioner

A uniform liquid device and uniform technology, applied in the field of heat exchange, can solve the problems of dry heating of heat exchange tube bundles and high assembly precision requirements, and achieve the effects of avoiding suction with liquid, improving the effect of uniform distribution, and lengthening the flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] First of all, those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention. For example, although the following embodiments are described in conjunction with the application of the liquid equalizing device to an air conditioner as an example, the liquid equalizing device of the present invention can also be applied to other heat exchange equipment or engineering equipment. The adjustment and Changes do not constitute limitations to the present invention, and all should be limited within the protection scope of the present invention.

[0028] It should be noted that, in the description of the present invention, the terms "middle", "upper", "lower", "top", "bottom", "left", "right", "front", "rear", " The terms such as "inside", "outside" and other indicated directions or positional relationships are based on the dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com