Special heating type composite yarn and production process thereof

A production process, heating type technology, applied in the field of yarn production, to achieve the effect of improving immunity, good spinnability and skin-friendly, and inhibiting the emission of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

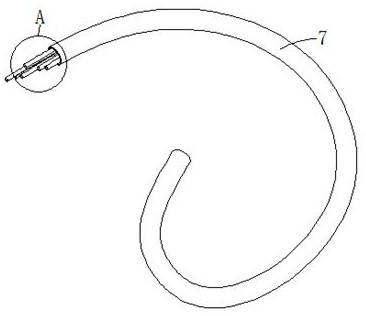

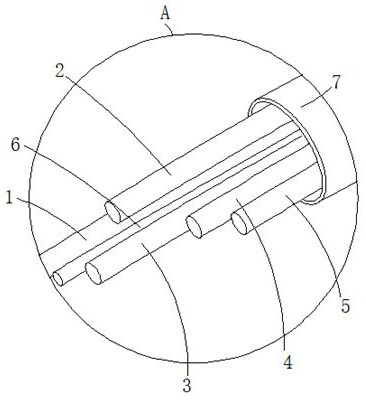

Image

Examples

Embodiment 1

[0042] A production process of a special heating type composite yarn, comprising the following steps:

[0043] Step 1: Sliver making; Step 2: Pre-merging in one step; Step 3: Pre-merging in two steps; Step 4: Mixing in one step; Step 5: Mixing in two steps; Step 6: Roving process; Step 7: Spinning process; Step 8 : Winding into a package; among them,

[0044]In step 1: preparing composite strips of anion polyester fiber, apocynum fiber, modal fiber, chitin fiber, synthetic fiber and conductive fiber silk respectively.

[0045] The preparation method of negative ion polyester fiber strip, comprises the following steps:

[0046] S1. Mix 10 parts of zirconium dioxide, 10 parts of silicon dioxide and 20 parts of titanium dioxide, sinter and pulverize to a ceramic powder with an average particle size of 0.2 microns.

[0047] S2. Mix 20 parts of isopropyl trititanate, 10 parts of 1,2-glyceryl stearate and 20 parts of glyceryl monostearate to prepare a coupling agent.

[0048] S3....

Embodiment 2

[0063] A production process of a special heating type composite yarn, comprising the following steps:

[0064] Step 1: Sliver making; Step 2: Pre-merging in one step; Step 3: Pre-merging in two steps; Step 4: Mixing in one step; Step 5: Mixing in two steps; Step 6: Roving process; Step 7: Spinning process; Step 8 : Winding into a package; among them,

[0065] In step 1: preparing composite strips of anion polyester fiber, apocynum fiber, modal fiber, chitin fiber, synthetic fiber and conductive fiber silk respectively.

[0066] The preparation method of negative ion polyester fiber strip, comprises the following steps:

[0067] S1. Mix 20 parts of zirconium dioxide, 30 parts of silicon dioxide and 40 parts of titanium dioxide, sinter and pulverize to a ceramic powder with an average particle size of 0.6 microns.

[0068] S2. Mix 30 parts of isopropyl trititanate, 20 parts of 1,2-glyceryl stearate and 30 parts of glyceryl monostearate to prepare a coupling agent.

[0069] S3...

Embodiment 3

[0084] A production process of a special heating type composite yarn, comprising the following steps:

[0085] Step 1: Sliver making; Step 2: Pre-merging in one step; Step 3: Pre-merging in two steps; Step 4: Mixing in one step; Step 5: Mixing in two steps; Step 6: Roving process; Step 7: Spinning process; Step 8 : Winding into a package; among them,

[0086] In step 1: preparing composite strips of anion polyester fiber, apocynum fiber, modal fiber, chitin fiber, synthetic fiber and conductive fiber silk respectively.

[0087] The preparation method of negative ion polyester fiber strip, comprises the following steps:

[0088] S1. Mix 30 parts of zirconium dioxide, 40 parts of silicon dioxide and 60 parts of titanium dioxide, sinter and pulverize to a ceramic powder with an average particle size of 0.8 microns.

[0089] S2. Mix 40 parts of isopropyl trititanate, 30 parts of 1,2-glyceryl stearate and 40 parts of glyceryl monostearate to prepare a coupling agent.

[0090] S3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com