Preparation of al-ti-ni crystal-amorphous composite material with aluminum-based alloy and its preparation method and application

An amorphous composite material, al-ti-ni technology, applied in the field of new crystalline/amorphous composite material preparation, can solve problems such as poor electrical conductivity, improve corrosion resistance, promote electron transport process, surface structure and chemical A stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1, prepare Al-Ti-Ni raw alloy strips according to the following components and atomic percentages: the content of Al is 75%-95%, the content of Ti is 2%-7%, and the content of Ni is 12%-20 %;

[0028] Step 2, cutting the Al-Ti-Ni original alloy strip obtained in step 1 into a strip with a thickness of 10 μm-30 μm, a width of 2 mm, and a length of 2 cm; Wash in deionized water and dry in air for later use;

[0029] Step 3, get the Al-Ti-Ni alloy strip that is made by step 2 and the potassium hydroxide solution that the molar concentration of 100ml is 0.8M-1.2M is placed in electrolyzer together and carries out electrochemical reaction, dealloying potential is- 0.8V~-1.05V (vs.Ag / AgCl), the reaction time is 4000s~6000s, the sample prepared after the reaction is rinsed with deionized water and dried in the air to obtain Al-Ti-Ni prepared from aluminum-based alloy Crystalline-amorphous composites.

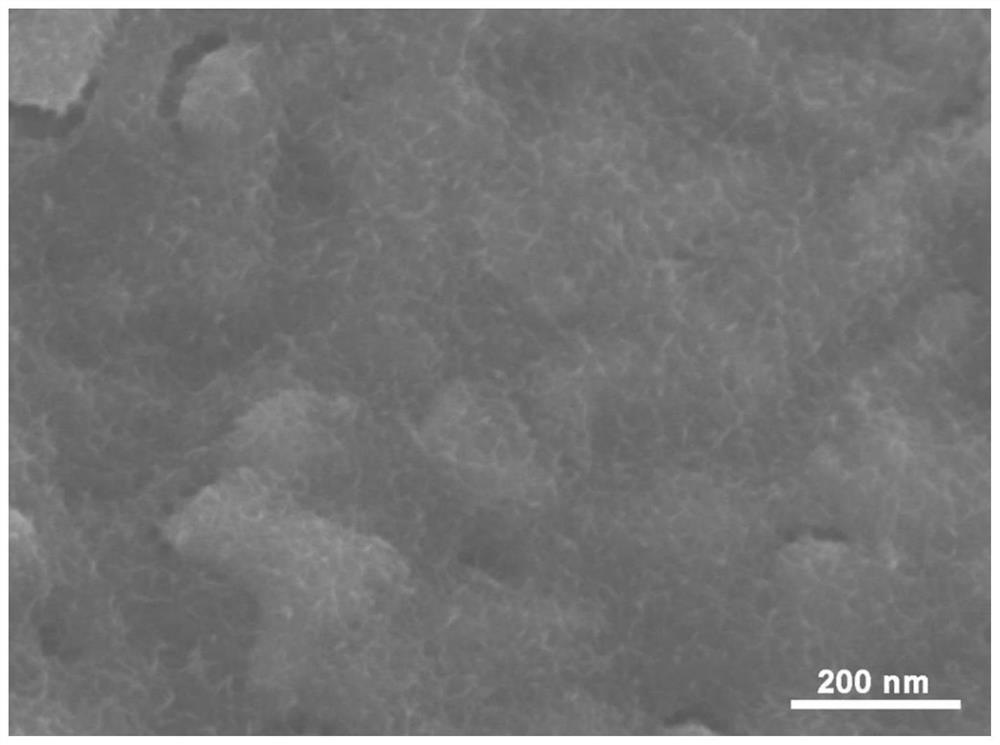

[0030] figure 1 The SEM figure of the Al-Ti-Ni crystal-amorphous c...

Embodiment 2

[0036] Step 1, prepare Al-Ti-Ni raw alloy strips according to the following components and atomic percentages: the content of Al is 75%-95%, the content of Ti is 7%-15%, and the content of Ni is 5%-12% %;

[0037] Step 2, cutting the Al-Ti-Ni original alloy strip obtained in step 1 into a strip with a thickness of 10 μm-30 μm, a width of 2 mm, and a length of 2 cm; Wash in deionized water and dry in air for later use;

[0038] Step 3, get the Al-Ti-Ni alloy strip that is made by step 2 and the potassium hydroxide solution that the molar concentration of 100ml is 0.8M-1.2M is placed in electrolyzer together and carries out electrochemical reaction, dealloying potential is- 0.65V~-0.85V (vs.Ag / AgCl), the electrochemical dealloying reaction time is 5000s~7000s, the sample prepared after the reaction is rinsed with deionized water, dried in the air, and the Al -Ti-Ni crystal-amorphous composite material.

[0039] figure 2 Shown is the SEM image of the Al-Ti-Ni crystal-amorpho...

Embodiment 3

[0044] Step 1, prepare Al-Ti-Ni raw alloy strips according to the following components and atomic percentages: the content of Al is 75%-95%, the content of Ti is 7%-15%, and the content of Ni is 5%-12% %;

[0045] Step 2, cutting the Al-Ti-Ni original alloy strip obtained in step 1 into strips with a thickness of 8-20 μm, a width of 1 mm, and a length of 1 cm; Wash in deionized water and dry in air for later use;

[0046] Step 3, get the Al-Ti-Ni alloy strip that is made by step 2 and the potassium hydroxide solution that the molar concentration of 100ml is 0.8M-1.2M is placed in electrolyzer together and carries out electrochemical reaction, dealloying potential is- 0.85V~-1.05V (vs.Ag / AgCl), the electrochemical dealloying reaction time is 5000s~7000s, the sample prepared after the reaction is rinsed with deionized water, dried in the air, and the Al -Ti-Ni crystal-amorphous composite material.

[0047] image 3 The SEM figure of the Al-Ti-Ni crystal-amorphous composite m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com