Binder and diaphragm, and preparation methods thereof

A binder and emulsifier technology, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of poor heat resistance of the separator, increased resistance of the separator, poor adhesion and heat resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

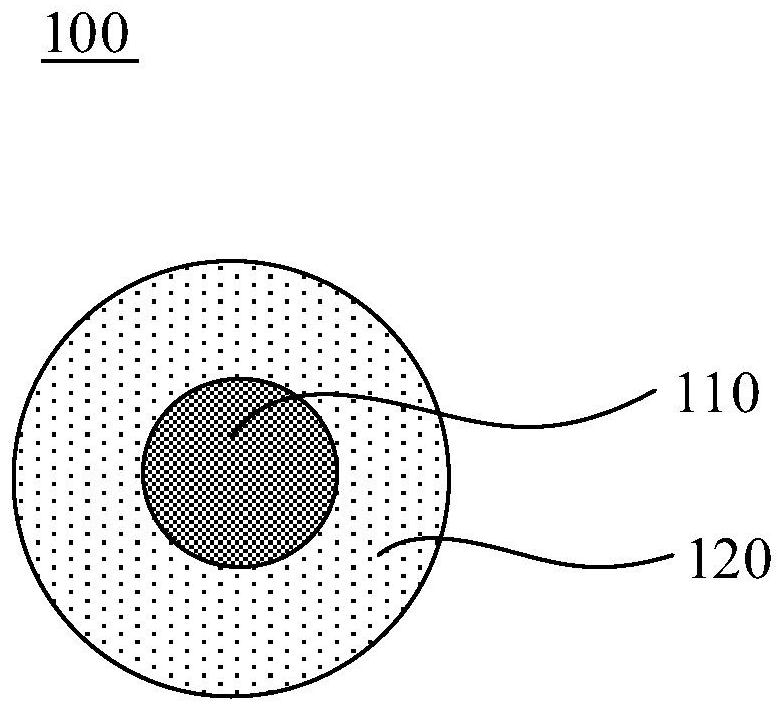

Image

Examples

preparation example Construction

[0046] A kind of preparation method of adhesive is wherein a kind of preparation method of above-mentioned adhesive, the preparation method of this adhesive comprises the following steps:

[0047] Step S210: Mix the first hard monomer, the solvent-resistant monomer, the first emulsifier and water to obtain a pre-emulsion of the core layer monomer.

[0048] Wherein, the mass of the first hard monomer accounts for 60%-95% of the total mass of the first hard monomer and the solvent-resistant monomer. Further, the first hard monomer is selected from one or a combination of two or more of methyl methacrylate, ethyl methacrylate, styrene, tert-butyl acrylate, n-butyl methacrylate, and acrylonitrile;

[0049] The mass of the solvent-resistant monomer accounts for 5% to 40% of the total mass of the first hard monomer and the solvent-resistant monomer. Further, the solvent-resistant monomer is selected from one or a combination of two or more of acrylonitrile, butyl methacrylate, and ...

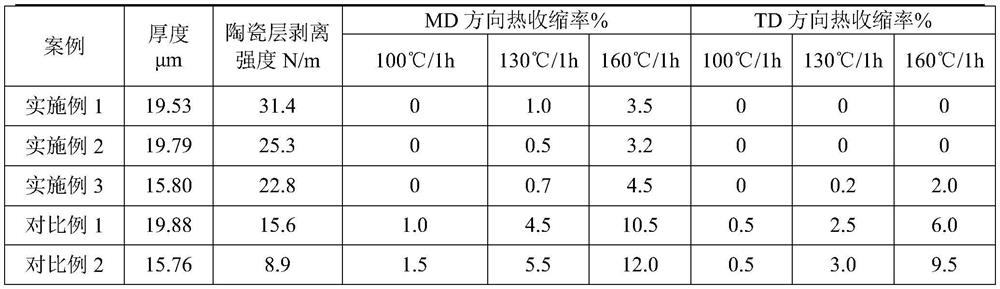

Embodiment 1

[0089] The preparation steps of the diaphragm of the present embodiment are as follows:

[0090] (1) At room temperature, add 86.0g of methyl methacrylate, 10.0g of ethyl methacrylate, 40.0g of styrene, 34.0g of acrylonitrile monomer, and 10.09g of sodium dodecylsulfonate into reactor A, Add 255.0 g of deionized water to disperse and emulsify under high-speed stirring to obtain a core layer monomer pre-emulsion.

[0091] (2) At room temperature, 30.0g methyl methacrylate, 34.0g n-butyl acrylate, 10.2g acrylic acid, 6.8g dimethylaminohexyl methacrylate, 4.3g propylene methacrylate, 6.73 g of sodium dodecyl sulfonate was added dropwise with 121.5 g of deionized water under high-speed stirring for dispersion and emulsification to obtain a shell monomer pre-emulsion.

[0092] (3) At room temperature, add 209.2g of deionized water to reactor C, add half of the core layer monomer pre-emulsion in stirring tank A under high-speed stirring, adjust the pH to 6-8; add 0.10g after heating ...

Embodiment 2

[0096] The preparation steps of the diaphragm of the present embodiment are as follows:

[0097] (1) At room temperature, add 86.0g of methyl methacrylate, 10.0g of ethyl methacrylate, 40.0g of styrene, 34.0g of acrylonitrile monomer, and 10.09g of sodium dodecylsulfonate into reactor A, Add 255.0 g of deionized water to disperse and emulsify under high-speed stirring to obtain a core layer monomer pre-emulsion.

[0098] (2) At room temperature, 30.0g methyl methacrylate, 34.0g n-butyl acrylate, 10.2g acrylic acid, 6.8g dimethylaminohexyl methacrylate, 4.3g propylene methacrylate, 6.73 g of sodium dodecyl sulfonate was added dropwise with 121.5 g of deionized water under high-speed stirring for dispersion and emulsification to obtain a shell monomer pre-emulsion.

[0099] (3) At room temperature, add 209.2g of deionized water to reactor C, add half of the core layer monomer pre-emulsion in stirring tank A under high-speed stirring, adjust the pH to 6-8; add 0.10g after heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com