Polydopamine modified tungsten-doped vanadium dioxide nanoparticle composite intelligent temperature control coating and preparation method thereof

A vanadium dioxide and nanoparticle technology, applied in vanadium oxide, coating and other directions, can solve the problems of complex preparation process and low modification efficiency, and achieve the effects of uniform particle size, mild reaction, and easy control of reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Step 1. Dissolve the weighed vanadyl sulfate in water, add oxalic acid, and stir at 40°C for 20 minutes to obtain a vanadyl sulfate solution reduced by oxalic acid;

[0051] Step 2. Dissolve the weighed tungstic acid in hydrogen peroxide solution, and sonicate at 30°C for 10 minutes to obtain a tungstic acid solution;

[0052] Step 3. Add the tungstic acid solution obtained in step 2 into the vanadyl sulfate solution obtained in step 1, and stir at 40°C for 0.5h to obtain a mixed solution;

[0053] Step 4. Transfer the mixed solution obtained in step 3 to a reaction kettle, and conduct a hydrothermal reaction at 180° C. for 5 hours to obtain a hydrothermal product;

[0054] Step 5. Cross-wash the hydrothermal product obtained in step 4 with water and ethanol, and dry it in an oven at 60°C for 6 hours to obtain a dried product;

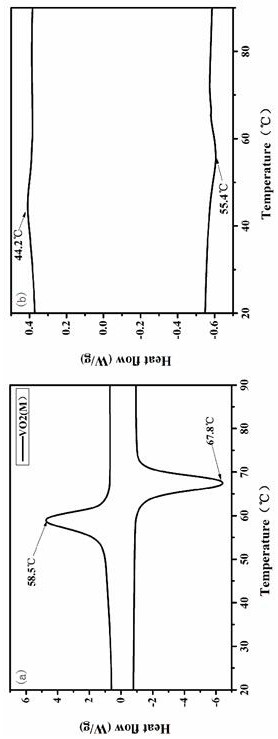

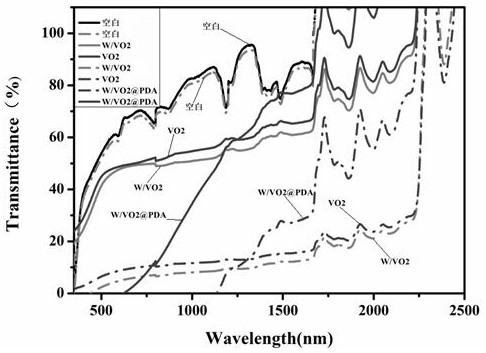

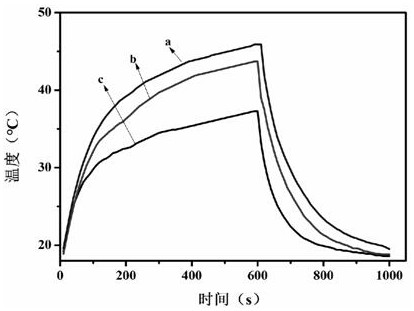

[0055] Step 6, performing high-temperature annealing on the dried product obtained in step 5 at 450° C. for 1 hour to obtain tungsten-doped va...

Embodiment 2

[0059] Step 1. Dissolve the weighed vanadium pentoxide in water, add acetic acid, and stir at 50° C. for 30 minutes to obtain a vanadium pentoxide solution reduced by acetic acid;

[0060] Step 2. Dissolve the weighed sodium tungstate in the hydrogen peroxide solution, and sonicate at 40°C for 20 minutes to obtain the sodium tungstate solution;

[0061] Step 3. Add the sodium tungstate solution obtained in step 2 to the vanadium pentoxide solution obtained in step 1, and stir at 50°C for 1 hour to obtain a mixed solution;

[0062] Step 4. Transfer the mixed solution obtained in step 3 to a reaction kettle, and conduct a hydrothermal reaction at 200° C. for 6 hours to obtain a hydrothermal product;

[0063] Step 5. Cross-wash the hydrothermal product obtained in step 4 with water and ethanol, and dry it in an oven at 70°C for 8 hours to obtain a dried product;

[0064] Step 6. Perform high-temperature annealing on the dried product obtained in step 5 at 550° C. for 2 hours to ...

Embodiment 3

[0068] Step 1. Dissolving the weighed vanadyl acetylacetonate in water, adding phthalic acid, and stirring at 60° C. for 40 minutes to obtain a solution of vanadyl acetylacetonate reduced by phthalic acid;

[0069] Step 2. Dissolve the weighed ammonium tungstate in hydrogen peroxide solution, and sonicate at 50°C for 30 minutes to obtain ammonium tungstate solution;

[0070] Step 3. Add the ammonium tungstate solution obtained in step 2 to the vanadyl acetylacetonate solution obtained in step 1, and stir at 60°C for 1.5 hours to obtain a mixed solution;

[0071] Step 4. Transfer the mixed solution obtained in step 3 to a reaction kettle, and conduct a hydrothermal reaction at 220° C. for 7 hours to obtain a hydrothermal product;

[0072] Step 5. Cross-wash the hydrothermal product obtained in step 4 with water and ethanol, and dry it in an oven at 80°C for 10 hours to obtain a dried product;

[0073] Step 6. Perform high-temperature annealing on the dried product obtained in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com