Method for preparing nano metal-organic framework material by using internal circulation rotating packed bed

A technology of rotating packed bed and nano metal is applied in the field of preparing nano metal-organic framework materials to achieve the effect of shortening reaction time and preventing contamination between batches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

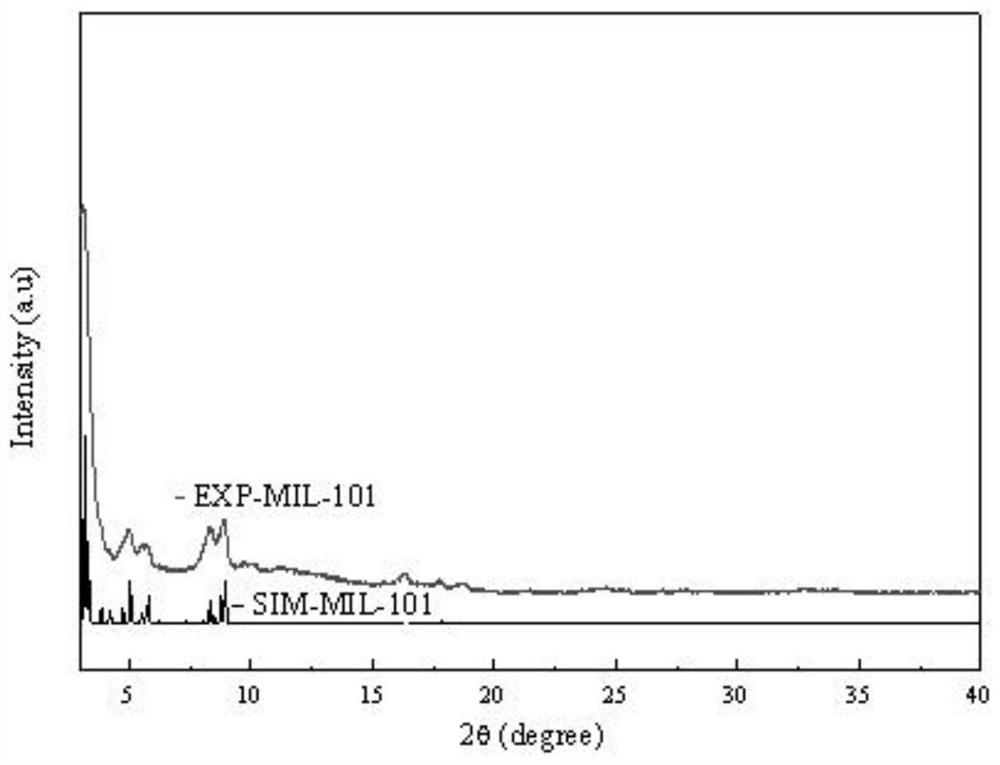

Image

Examples

Embodiment 1

[0072] A method for preparing nano metal-organic framework materials using an internal circulation rotating packed bed, comprising the steps of:

[0073] 2.282g (14mmol) of ferric chloride was stirred and dissolved in 350mL of deionized water; 2.326g (14mmol) of terephthalic acid was stirred and dissolved in 350mL of N,N'-dimethylformamide; 100mL of the precursor solution (deionized Water: N,N'-dimethylformamide=1:1); Add the precursor solution into the internal circulation rotating packed bed through the feed port, open the internal circulation rotating packed bed device, and adjust the rotor speed to 1500rpm; Ferric chloride solution and terephthalic acid solution were simultaneously pumped into the internal circulation packed rotary bed for precipitation and crystallization reaction, and the feed rate on both sides was controlled to be 100mL / min, and the circulating water controlled the reaction temperature to 90°C; After the material is finished, wait for the material to r...

Embodiment 2

[0078] A method for preparing nano metal-organic framework materials using an internal circulation rotating packed bed, comprising the steps of:

[0079] Stir and dissolve 2.900g (9mmol) of zirconium oxychloride octahydrate in 300mL N,N'-dimethylformamide; stir and dissolve 1.495g (9mmol) of terephthalic acid in 300mL solvent (N,N'-dimethylformamide Formamide: formic acid=9:1); configure the precursor solution: stir and dissolve 0.967 g (3 mmol) of zirconium oxychloride octahydrate in 100 mL N, N'-dimethylformamide; pass the precursor solution through the feed Put it into the internal circulation rotating packed bed, turn on the internal circulation rotating packed bed device, and adjust the rotor speed to 1500rpm; pump zirconium oxychloride octahydrate solution and terephthalic acid solution into the internal circulation rotating packed bed at the same time for precipitation and crystallization React, and control the feed rate on both sides to be 100mL / min, and the circulatin...

Embodiment 3

[0084] Repeat Example 1, the difference is only: the soluble metal salt is selected from one or more of the following substances: ferric nitrate, ferric sulfate; the effect obtained is similar to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com