Production method of thiophene-2-ethylamine

A production method, thiophene technology, applied in the production field of thiophene-2-ethylamine, can solve the problems of product purity, low conversion rate, production efficiency, complicated process, etc., and achieve high product conversion rate and production efficiency, and simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

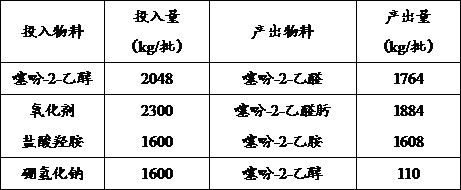

[0024] This embodiment provides a kind of production method of thiophene-2-ethylamine, it comprises the following steps:

[0025] S1, put 2048kg thiophene-2-ethanol and 2000kg oxidant in 70m 3 Oxidation reaction in n-hexane gives thiophene-2-acetaldehyde.

[0026] S2. After reacting 1764kg of thiophene-2-acetaldehyde and 1500kg of hydroxylamine hydrochloride in 4000kg of 90% ethanol solution, extract with dichloromethane, dry over anhydrous magnesium sulfate, and distill to obtain thiophene-2- Acetaldehyde oxime.

[0027] S3, place 1884kg of thiophene-2-aldoxime and 1500kg of sodium borohydride in 6000kg of cold tetrahydrofuran solution for reduction reaction, then extract with ethyl acetate, dry over anhydrous magnesium sulfate, and distill under reduced pressure The product thiophene-2-ethylamine was obtained.

Embodiment 2

[0029] This embodiment provides a kind of production method of thiophene-2-ethylamine, it comprises the following steps:

[0030] S1, put 2048kg thiophene-2-ethanol and 2300kg oxidant in 90m 3 Oxidation reaction in n-hexane gives thiophene-2-acetaldehyde.

[0031] S2. After reacting 1764kg of thiophene-2-acetaldehyde and 1700kg of hydroxylamine hydrochloride in 7000kg of 95% ethanol solution, extract with dichloromethane, dry over anhydrous magnesium sulfate, and obtain thiophene-2- Acetaldehyde oxime.

[0032] S3, place 1884kg of thiophene-2-aldoxime and 1700kg of sodium borohydride in 8000kg of cold tetrahydrofuran solution for reduction reaction, then extract with ethyl acetate, dry over anhydrous magnesium sulfate, and distill under reduced pressure The product thiophene-2-ethylamine was obtained.

Embodiment 3

[0034] This embodiment provides a kind of production method of thiophene-2-ethylamine, it comprises the following steps:

[0035] S1, put 2048kg thiophene-2-ethanol and 2300kg oxidant in 75m 3 Oxidation reaction in n-hexane gives thiophene-2-acetaldehyde.

[0036] S2. After reacting 1764kg of thiophene-2-acetaldehyde and 1600kg of hydroxylamine hydrochloride in 5000kg of 92% ethanol solution, they were extracted with dichloromethane, dried over anhydrous magnesium sulfate, and distilled to obtain thiophene-2- Aldoxime.

[0037] S3, place 1884kg of thiophene-2-glyoxaldoxime and 1600kg of sodium borohydride in 6500kg of cold tetrahydrofuran solution for reduction reaction, then extract with ethyl acetate, dry over anhydrous magnesium sulfate, and distill under reduced pressure The product thiophene-2-ethylamine was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com