High-volume solid waste concrete and preparation method thereof

A technology of waste concrete and large dosage, applied in the field of comprehensive utilization of solid waste and building materials, can solve the problems of low strength, low strength of recycled concrete, and many micro-cracks, so as to reduce production costs, increase the proportion of recycled aggregates, alleviate the extreme scarcity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

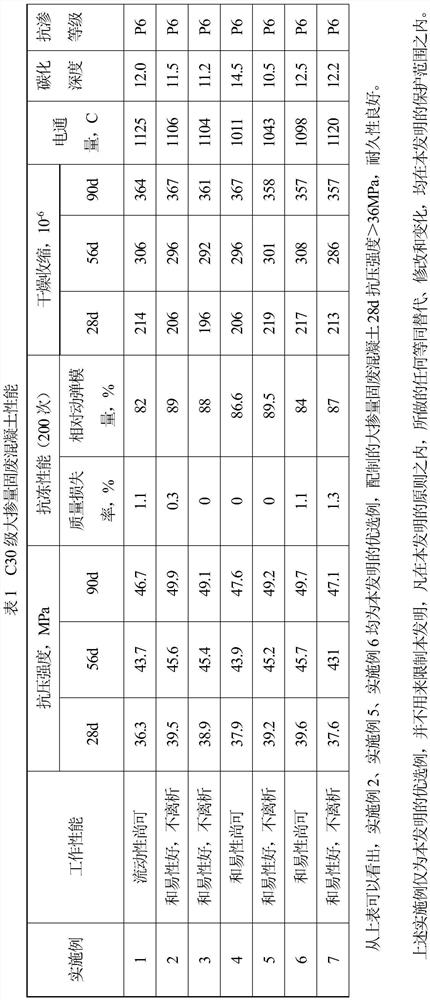

Examples

preparation example Construction

[0029] The preparation method of embodiment 1~embodiment 7 is:

[0030] (1) Take steel slag, fly ash, mineral powder by weight of composite admixture, add in mixing container, mix 5min to fully mix, make composite admixture;

[0031] (2) Weigh various raw materials according to the weight of C30 large-volume solid waste concrete, add tailings machine-made sand, regenerated fine aggregate, natural sand, composite admixture, cement in the order of feeding, stir for 30 seconds, and then add Reinforced recycled coarse aggregate for reticular methyl silicone waterproof membrane, stir for 30s to make the dry material mix evenly;

[0032] (3) Add part of water and admixture to the dry material, and stir for 1 minute to make the slurry on the surface of the aggregate evenly coated; then add the remaining water and admixture, and stir for 2 minutes to take out the mixer.

[0033] The strength and stability of the large-volume solid waste concrete provided in this example are greatly i...

Embodiment 1

[0036] per m 3 The concrete takes the following parts by weight:

[0037] P·O4 2.5 cement 181kg, composite admixture (steel slag: fly ash: mineral powder = 8:60:32) 182kg, tailings machine-made sand 351kg, natural sand 424kg, reinforced recycled coarse aggregate (regenerated coarse aggregate After soaking in water glass with a mass concentration of 3% and a modulus of 3.2 for 10 minutes), 1070kg, 3.63kg of polycarboxylate superplasticizer, and 182kg of water.

Embodiment 2

[0039] per m 3 The concrete takes the following parts by weight:

[0040] P·O4 2.5 cement 173kg, composite admixture (steel slag: fly ash: mineral powder = 50:10:40) 172kg, tailings machine-made sand 362kg, natural sand 420kg, reinforced recycled coarse aggregate (regenerated coarse aggregate After soaking in 1% potassium methyl silicate solution with a mass concentration of 5min), 1080kg, 3.11kg of polycarboxylate superplasticizer, and 176kg of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com