3D printing antibacterial product

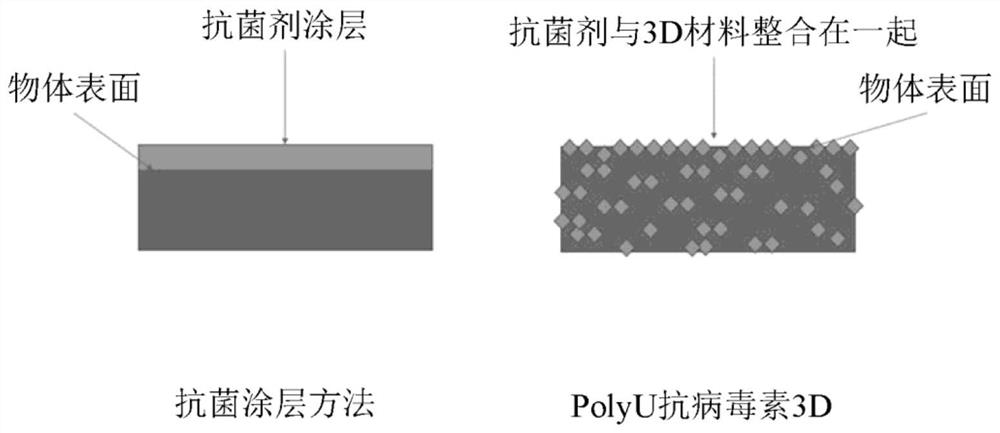

An antibacterial agent and 3D printing technology, applied in the field of preparing 3D printing products with antibacterial activity, can solve the problems of increasing additional costs and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0065] Example 1: Parallel dash test

[0066] Two 3D printed materials were tested to determine the inhibitory effect of the 3D printed materials prepared using the methods of the present disclosure. Two bacteria commonly found in the environment were tested -- Staphylococcus aureus (S. aureus) (Gram-positive) and K. pneumoniae (Gram-negative).

[0067] The test for antimicrobial efficacy is based on a modified method of AATCC test method 147, which is also known as the parallel streak test. This method is useful for obtaining a rough estimate of activity because the growth of the inoculum organism decreases from one end of each streak to the other and from one streak to the next, allowing for increased sensitivity. The size of the zone of inhibition and the narrowing of the scribe line by the presence of the antimicrobial agent allows estimation of residual antimicrobial activity after multiple washes (AATCC).

[0068] In this test, an ABS-based UV-sensitive resin was selec...

example 2

[0076] Example 2: Surface wear test

[0077] Perform surface wear tests to determine antimicrobial activity inside 3D printed products. PHMB (10% by weight) and Zinc Oxide (2.5% by weight) were added to HTM 140 resin and printed by the method of the present disclosure using DLP technology and before the samples were subjected to the modified AATCC Test Method 147 as described above Use a cutter to scrape off the surface of the printed material. Place the abraded surface down (contacting the Petri dish).

[0078] After culturing Klebsiella pneumoniae with the samples, a width of inhibition of 0.067 was observed, thus demonstrating the antibacterial effect of the interior of the 3D printed material against Klebsiella pneumoniae.

example 3

[0079] Example 3: Parallel streak testing of samples formed with mixtures

[0080] The experiments were repeated using ABS-tough, another 3D printing resin with some inherent basic antimicrobial functions. The resin was mixed with a significantly smaller amount of water-based PHMB (1% by net weight).

[0081] Instead of using an ultrasonic mixer, alcohol is used as a mixing agent to improve the mixing quality. The modified AATCC test method 147 was repeated, and the results showed that the 3D printed samples showed a stronger antibacterial effect against Staphylococcus aureus, while all samples did not allow bacteria to grow on the samples. This indicates that the surface of the sample has an effective antibacterial function.

[0082] Figure 8 and 9 demonstrates the activity of 3D printed sample materials prepared with resin integrated with different amounts of PHMB at a ratio of 1:1 with and without worn surfaces before testing Combine with 99% ethanol. Figure 8 depic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com