A motor and a control system for reversing the motor

A technology of control system and inversion circuit, applied in the direction of controlling mechanical energy, electric motor/converter plug, electromechanical device, etc., can solve the problems of increased space occupation and high cost, and achieve the effect of prolonging the moving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be further described with reference to the accompanying drawings.

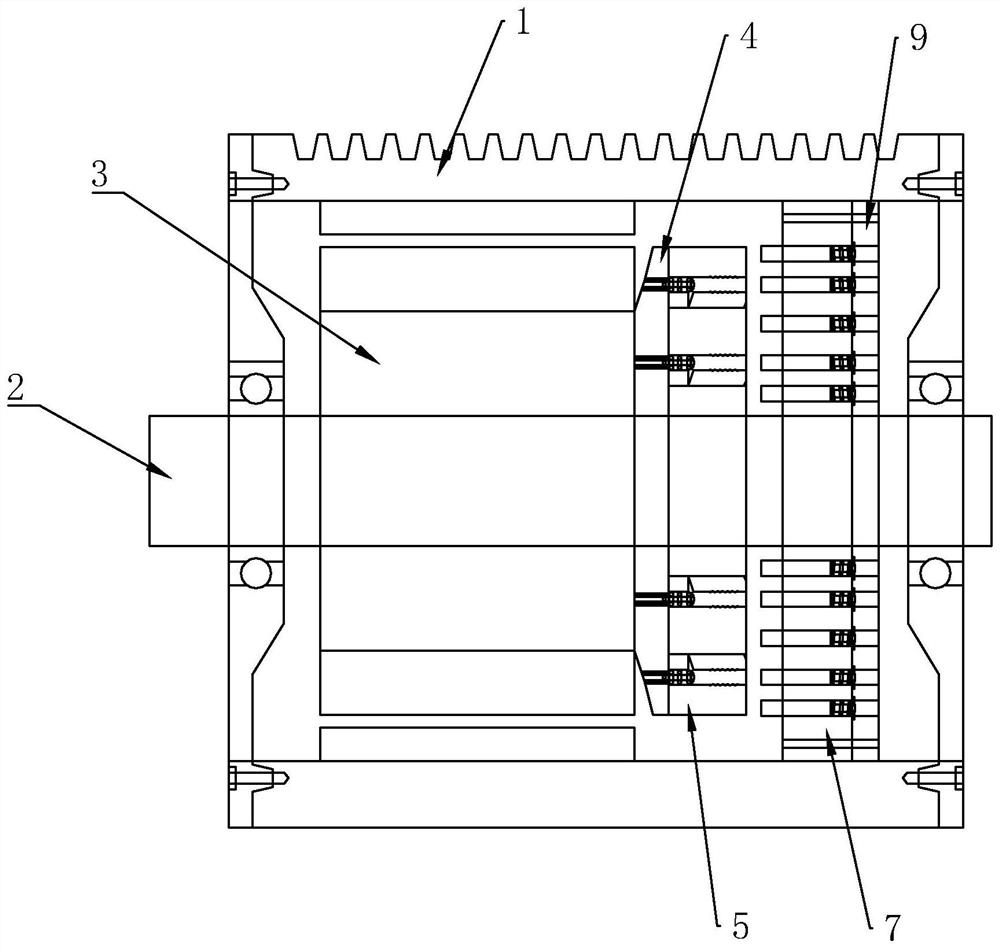

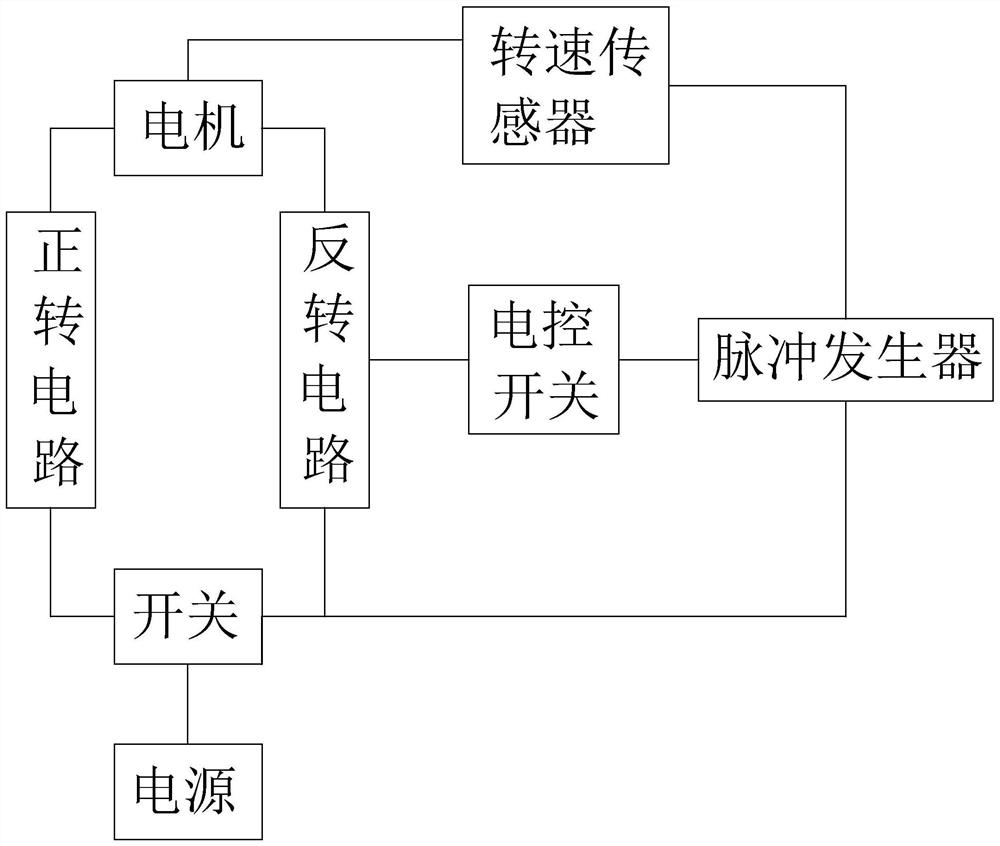

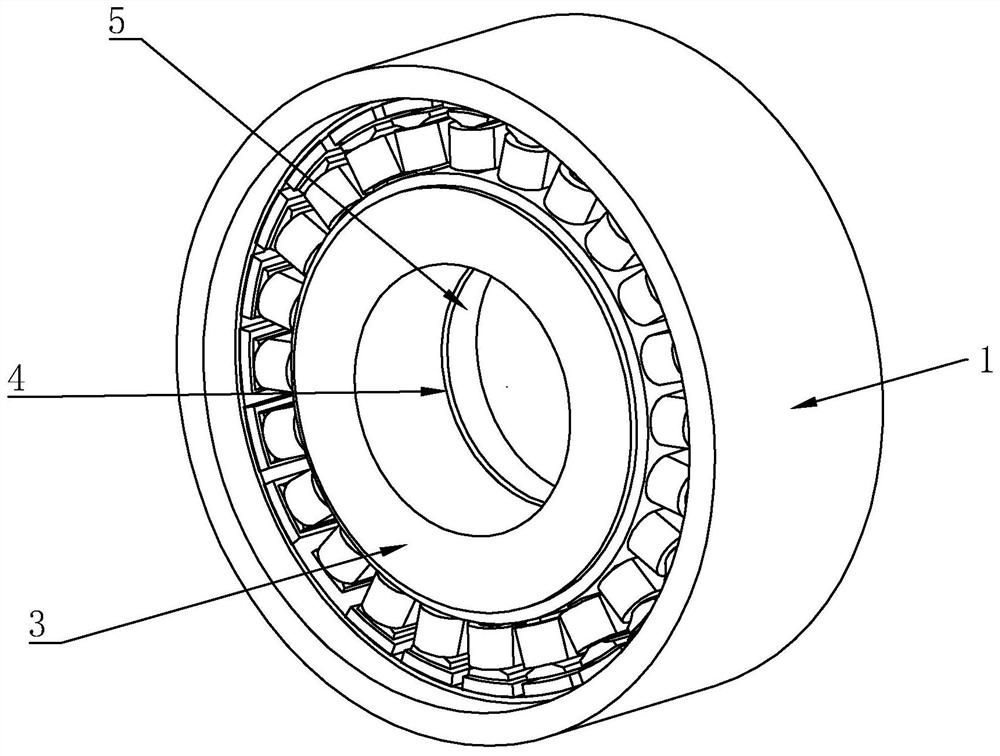

[0035] refer to Figures 1 to 3 As shown, a motor and a control system for reversing the motor, the motor includes a casing 1 and a rotor arranged in the casing 1, the rotor includes a rotating shaft 2, an iron core 3 and a coil, and the iron core 3 is fixed on the rotating shaft 2, the coil is set on the wire teeth of the iron core 3, a rotating chuck is installed on the rotor, and a fixed chuck is installed in the casing 1, and the rotating chuck and the fixed chuck are on the same side of the rotor. The control system includes a speed sensor, a pulse generator, an electric control switch and a two-way switch. The two-way switch makes the motor generate a forward rotation circuit and a reverse rotation circuit. The pulse generator and the electric control switch are connected to the reverse circuit, and the speed sensor is installed on the rotor. , and send a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com