Continuous and automatic aerobic bacterium cultivation system

A technology for cultivating aerobic bacteria and strains, applied in biochemical instruments, biochemical cleaning devices, biochemical equipment and methods, etc., can solve problems affecting the quality of final products, difficult to eliminate miscellaneous bacteria, unsuitable for cultivation, etc., to achieve Continuous automatic production, avoiding the interference of miscellaneous bacteria, improving the efficiency of cultivation and the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

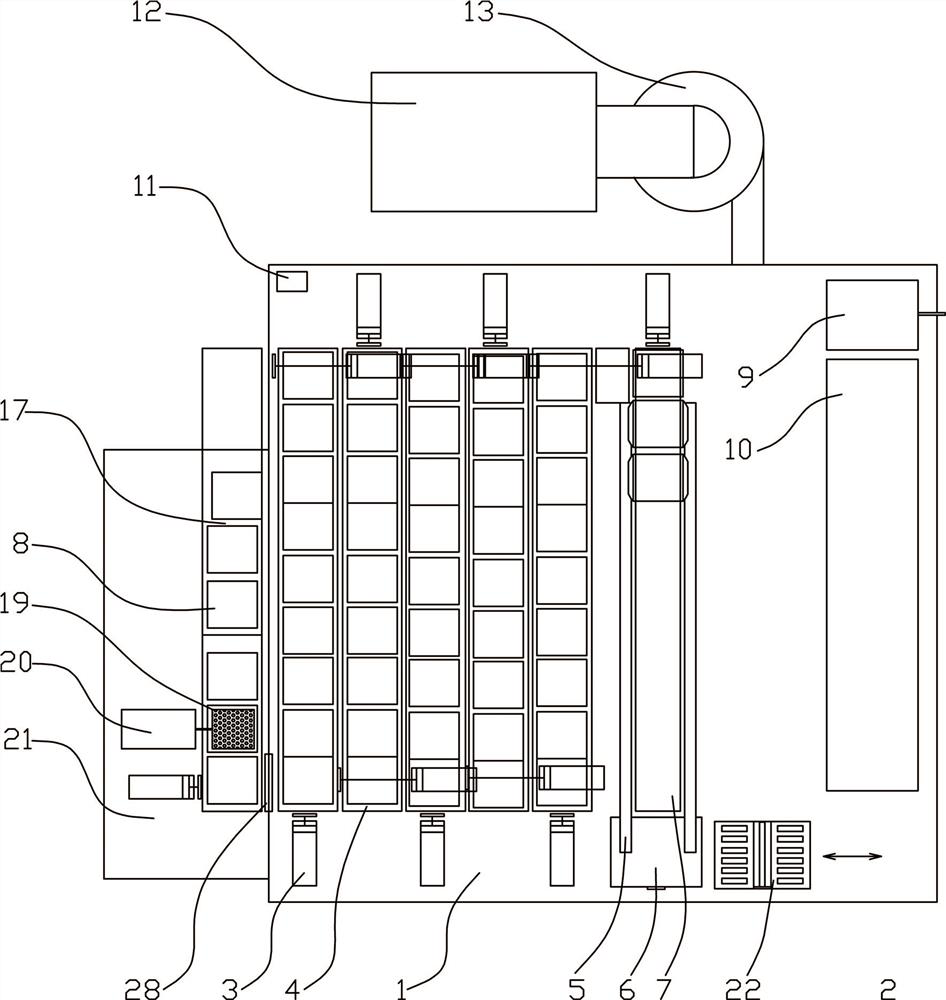

[0037] Such as figure 1 Among them, a continuous automatic cultivation system for aerobic bacteria, which includes a strain cultivation area 1;

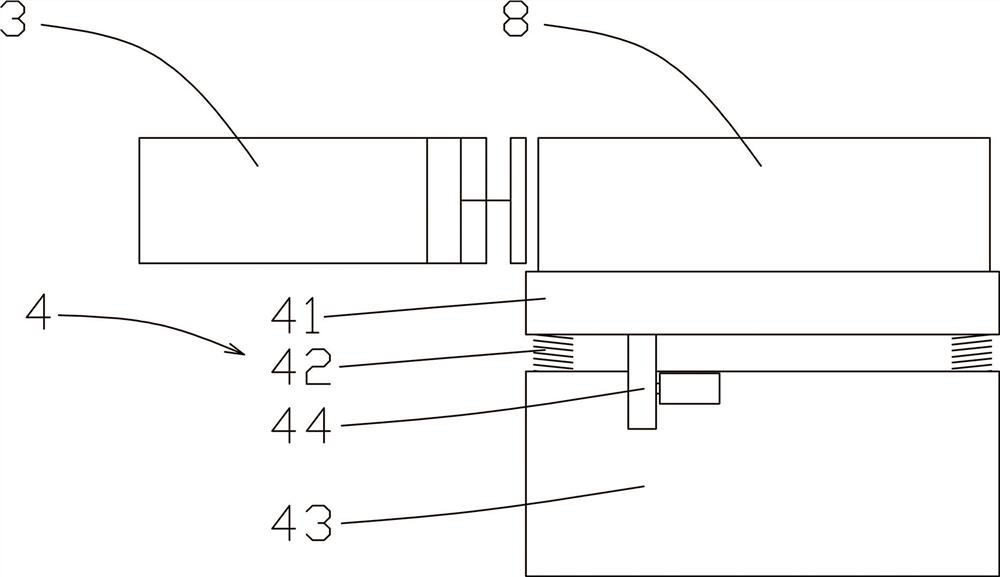

[0038] The strain cultivation area 1 is provided with a plurality of shaking platforms 4 interconnected to form a production line, and the strain cultivation box 8 is driven to walk along the production line of the shaking platform 4 through a plurality of push-pull conveying devices 3 to complete strain cultivation. With this structure, continuous and automatic aerobic bacteria cultivation can be realized through the automatic stepping of the strain cultivation box 8 . The time for the strain culture box 8 to walk from the head end to the tail end of the shaking platform 4 production line is the time for cultivating and maturing the aerobic bacteria.

[0039] The preferred solution is as Figure 5~7 Among them, the structure of the strain culture box 8 is as follows: the two sides of the box body 81 are provided with openable side...

Embodiment 2

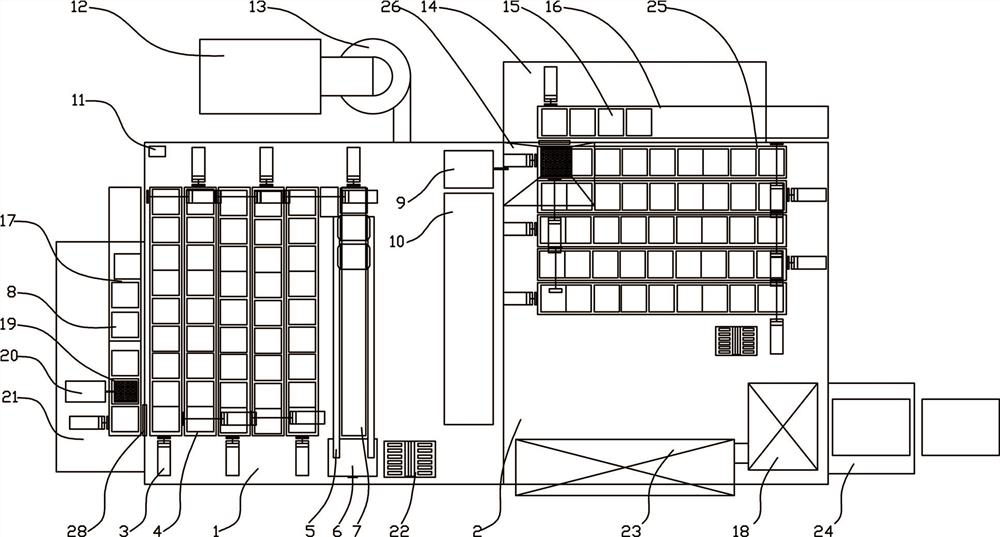

[0059] On the basis of Example 1, such as figure 2 Among them, a kind of natto automatic production system, it comprises strain cultivating area 1 and solid fermentation area 2;

[0060] The structure of the strain cultivation area 1 is the same as in Example 1. The moving time of the strain cultivation box 8 in the strain cultivation area 1 is 12-18 hours. The temperature in the strain cultivation area 1 is controlled at 30-37°C.

[0061] Such as figure 1 Among them, the strain cultivation area 1 is provided with a bacterial liquid collection platform 7 for collecting the bacterial liquid in the bacterial strain cultivation box 8; the collected bacterial liquid is contained in the bacterial liquid box 6 for delivery to the bacterial liquid inoculation box 26 .

[0062] The solid fermentation area 2 is equipped with a bacterial liquid inoculation box 26, which is used to inoculate the beans in the bean fermentation box 15 with the collected bacterial liquid; the bacterial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com