High-impact polypropylene material and preparation method thereof

A high-impact polypropylene and polypropylene technology, applied in the field of polymer materials, can solve the problems of high shrinkage rate and low notched impact strength, and achieve the effect of improving rigidity, changing physical and mechanical properties, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

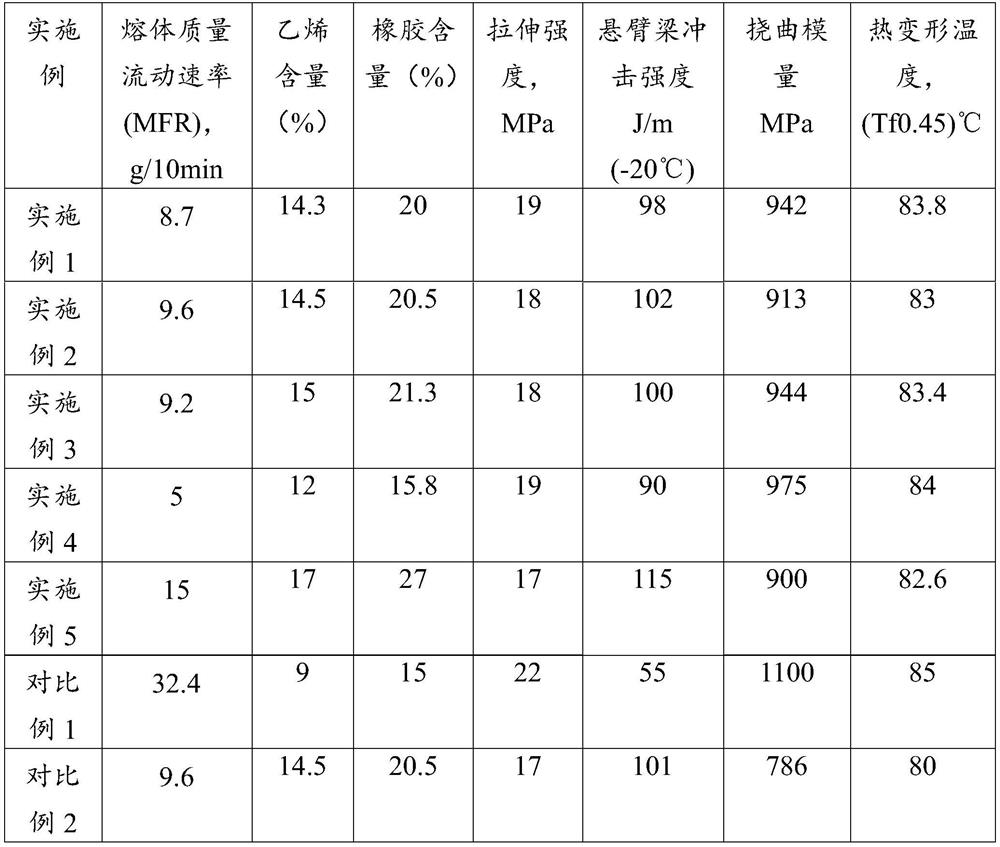

Examples

Embodiment 1

[0025] This example is a high-impact polypropylene material provided by the present invention, which includes the following raw materials in parts by mass: 99.62 parts of polypropylene powder, 0.1 part of primary antioxidant 1010, 0.08 part of auxiliary antioxidant 168 and components 0.2 parts of nuclear agent.

[0026] The preparation method of above-mentioned high-impact polypropylene material comprises the following steps:

[0027] (1) Polymerize with propylene, ethylene and hydrogen as raw materials to obtain polypropylene powder with ethylene content of 14.3%, rubber content of 20%, and melt flow rate of 8.7g / 10min (measured according to GB3682);

[0028] (2) According to the proportioning ratio, the polypropylene powder described in step (1) is mixed with the main antioxidant 1010, the auxiliary antioxidant 168, and the nucleating agent to obtain a mixed material;

[0029] (3) The mixed material described in step (2) is added in the extruder (the load is 10 tons / hour), ...

Embodiment 2

[0031] This embodiment is a high-impact polypropylene material provided by the present invention, which includes the following raw materials in parts by mass: 99.5 parts of polypropylene powder, 0.15 parts of primary antioxidant 1010, 0.1 part of auxiliary antioxidant 168 and components 0.25 parts of nuclear agent.

[0032] The preparation method of above-mentioned high-impact polypropylene material comprises the following steps:

[0033] (1) Carry out polymerization with propylene, ethylene and hydrogen as raw materials, the obtained ethylene content is 14.5%, the rubber content is 20.5%, and the melt flow rate is the polypropylene powder of 9.5g / 10min (measured according to GB3682);

[0034] (2) According to the proportioning ratio, the polypropylene powder described in step (1) is mixed with the main antioxidant 1010, the auxiliary antioxidant 168, and the nucleating agent to obtain a mixed material;

[0035] (3) The mixed material described in step (2) is added in the ext...

Embodiment 3

[0037] This embodiment is a high-impact polypropylene material provided by the present invention, which includes the following raw materials in parts by mass: 99.57 parts of polypropylene powder, 0.1 part of primary antioxidant 1010, 0.1 part of auxiliary antioxidant 168 and components 0.23 parts of nuclear agent.

[0038] The preparation method of above-mentioned high-impact polypropylene material comprises the following steps:

[0039] (1) Carry out polymerization with propylene, ethylene and hydrogen as raw materials, the obtained ethylene content is 15%, the rubber content is 21.3%, and the melt flow rate is the polypropylene powder of 9.3g / 10min (measured according to GB3682);

[0040] (2) According to the proportioning ratio, the polypropylene powder described in step (1) is mixed with the main antioxidant 1010, the auxiliary antioxidant 168, and the nucleating agent to obtain a mixed material;

[0041] (3) The mixed material described in step (2) is added in the extrud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com