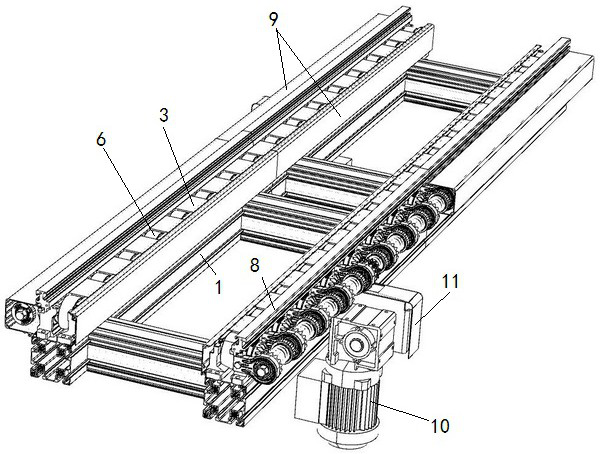

Double-support roller line

A roller table line, double support technology, applied in the direction of roller table, roller column, conveyor objects, etc., can solve the problems of poor gear meshing, long processing cycle, too fast wear, etc., to achieve easy maintenance and replacement, good assembly and flexible assembly sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the structure and function of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

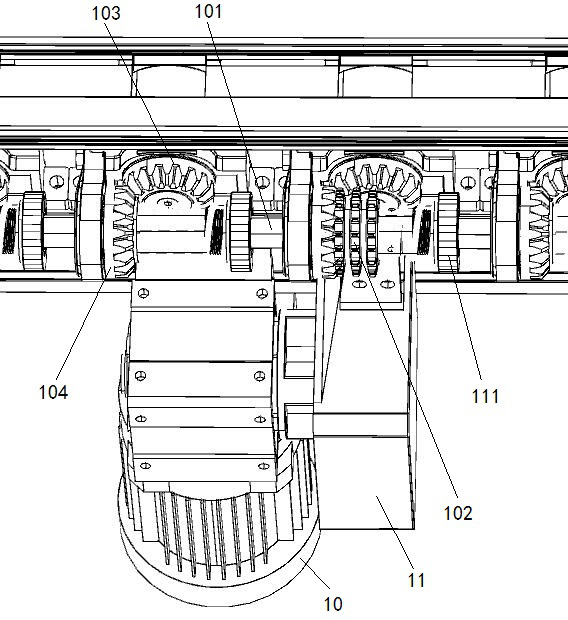

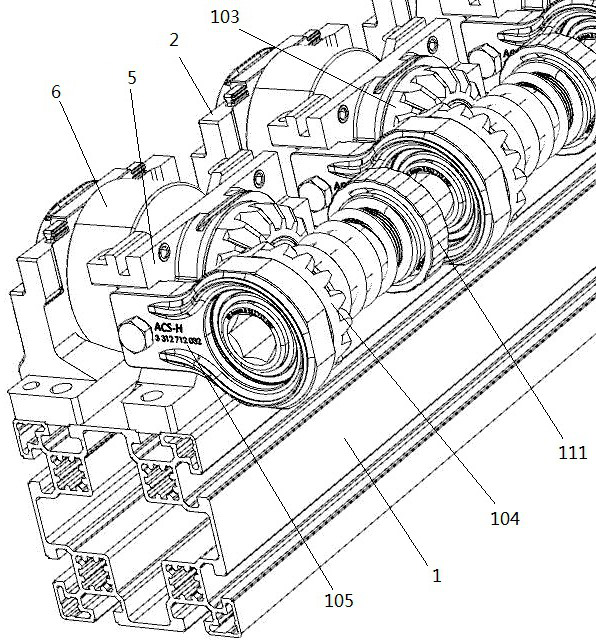

[0033] See attached Figure 1-10, double support roller line, including support frames 1 on both sides parallel to each other, a number of rollers 6 are arranged in sequence on the support frame 1 on each side, the center of the rollers 6 is connected with a roller shaft 4 that rotates synchronously with the rollers 6, and the roller shaft 4, one end is fixed by the auxiliary base 2, the other end of the roller shaft 4 is fixed by the fixed module seat 5, the auxiliary base 2 and the fixed module seat 5 are detachably installed on the support frame 1, and each fixed module seat 5 is installed with a set of The transmission unit that drives the roller shaft to rotate, and the drive mechanism outputs the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com