Bottom fork and motor connection structure of electric bicycle

A technology of electric bicycles and connection structures, which is applied to bicycles, motor vehicles, motorcycles, etc., can solve problems such as inability to install, and achieve the effects of convenient installation, high connection strength, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

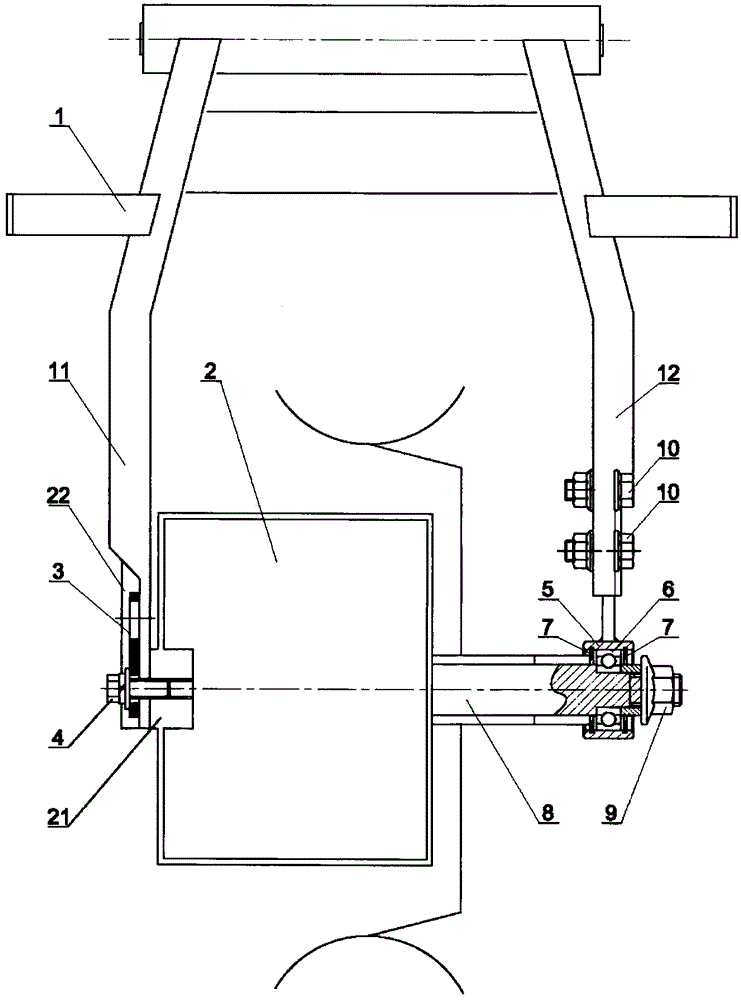

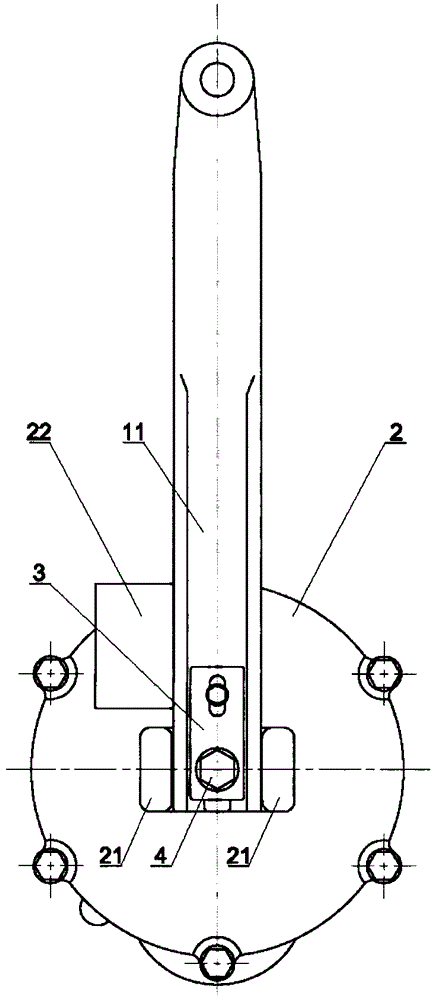

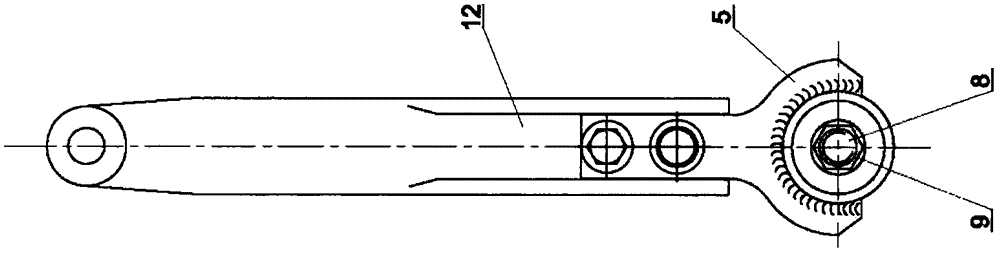

[0011] Such as figure 1 , figure 2 and image 3 As shown, a connection structure between a flat fork and a motor of an electric bicycle according to the present invention includes a flat fork 1 and a motor 2. The structure of the flat fork 1 is in the shape of "open" and has a first arm 11 and a second branch Arm 12, the end of the first arm 11 is fixed in the groove formed by the motor housing 21 on one side of the motor 2 through the anti-pull sheet 3 and the compression screw 4, the outer side of the motor 2 is on the side of the flat fork 1 The left side of the first arm 11 is processed with a motor outlet hole strap 22 that fits the first arm 11, and the second arm 12 is connected to the flat fork bearing seat 5 through the flat fork connecting screw 10. The fork bearing seat 5 is sleeved on one end of the output shaft 8 of the motor 2 through the bearing 6, and the flat fork bearing seat 5 forms a rotatable connection with the output shaft 8, and the inner ring of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com