Vertical processing method for internal key grooves of rigid magnet yoke

A processing technology and internal keyway technology, which is applied in the field of vertical processing technology for rigid yoke internal keyways, can solve the problems of relatively large processing technology limitations and relatively high requirements for processing equipment, and achieve shortened processing cycle, good application effect and simple operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

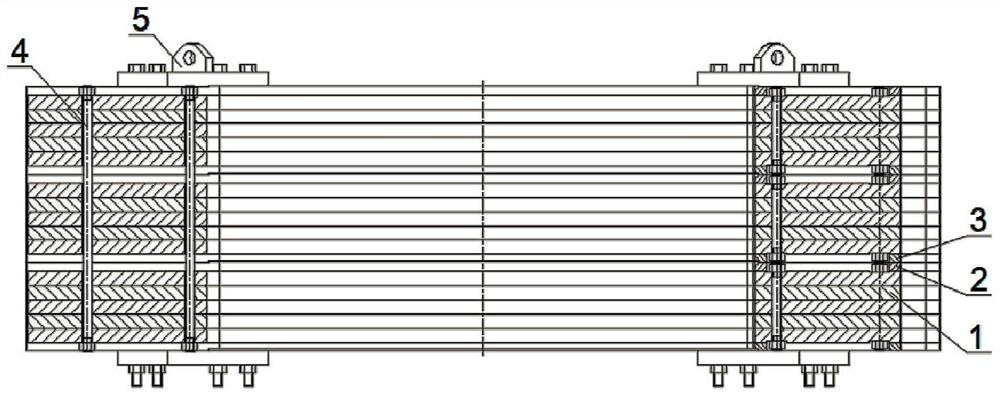

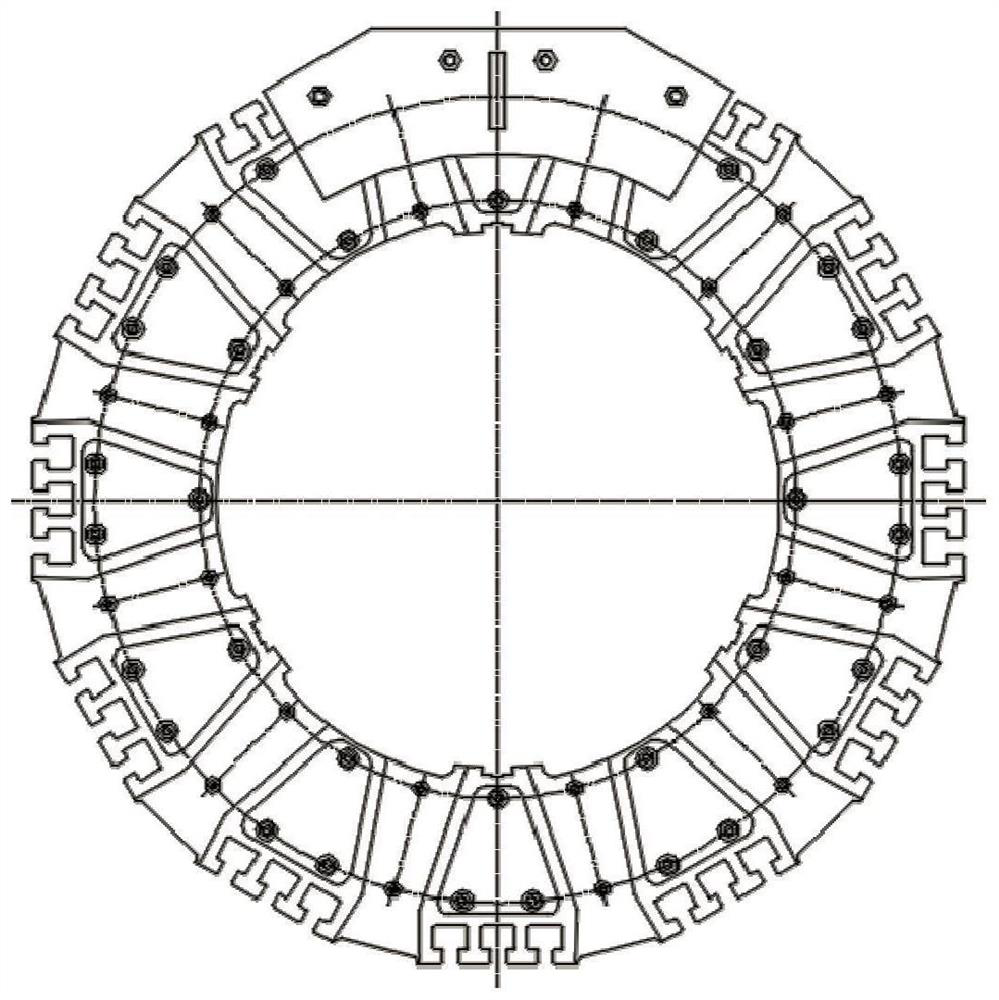

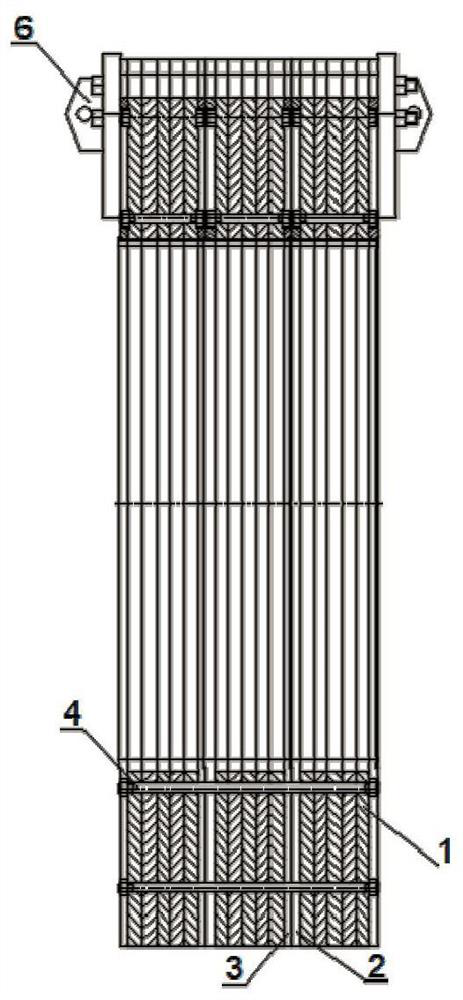

[0024] Such as figure 1 , figure 2 As shown, a vertical processing method for the inner keyway of the rigid yoke, while ensuring the quality of the inner keyway of the rigid yoke, the production cycle is shortened, the production efficiency is high, and the manufacturing accuracy is high. Technical scheme of the present invention is:

[0025] 1) The single-segment yoke section 1 is rounded according to the inner circle on the vertical lathe, and the point deviation is ≤0.30mm, taking into account the machining allowance of the outer circle. The plane thickness dimension and shape and position tolerance of the upper side air guide belt 2 and the lower side air guide belt 3 are ≤0.10mm, and the unilateral allowance of the inner circle of the car is 2mm;

[0026] 2) Assemble the three yoke sections 1 together on the vertical lathe, press the three yoke sections together with the tool screw 4, press the side air guide belt 3 to adjust the level to ≤0.10mm, and retest the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com