Slender object brazing coaxial positioning device capable of preventing brazing filler metal from flowing

A technology for coaxial positioning and slender objects, which is applied in auxiliary devices, welding equipment, metal processing equipment, etc., can solve the problems of poor coaxiality, decreased quality of welding products, economic losses, etc., to ensure brazing quality, Improve work efficiency and ensure economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the embodiments of the present invention will be clearly and completely described below. The embodiments of the present invention and all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

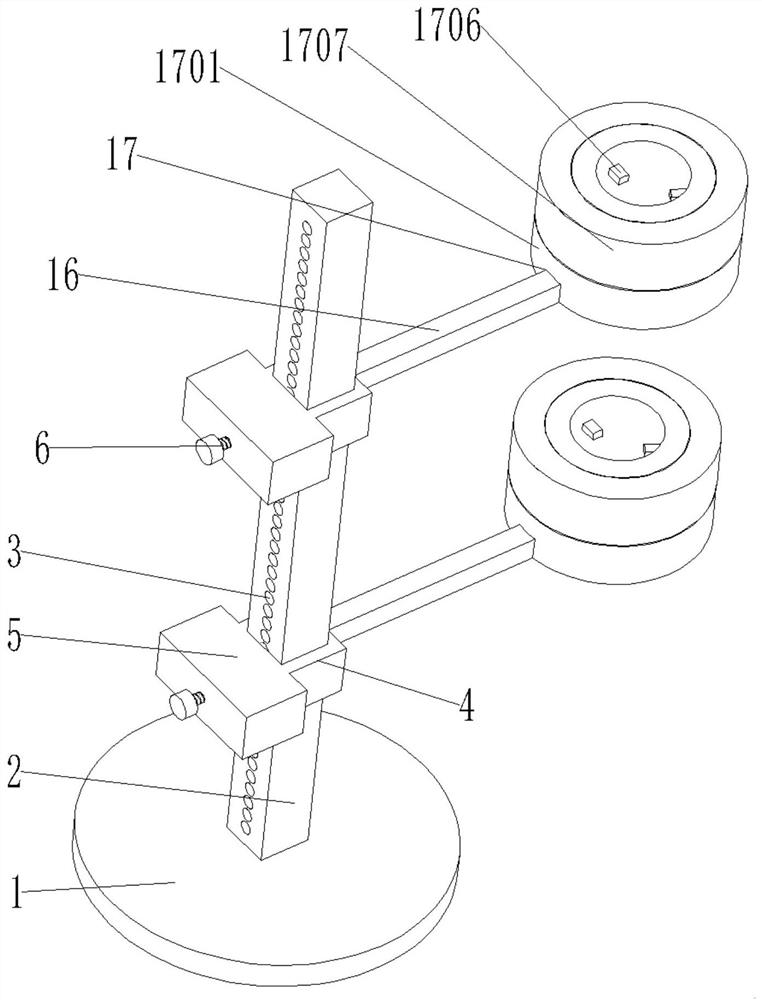

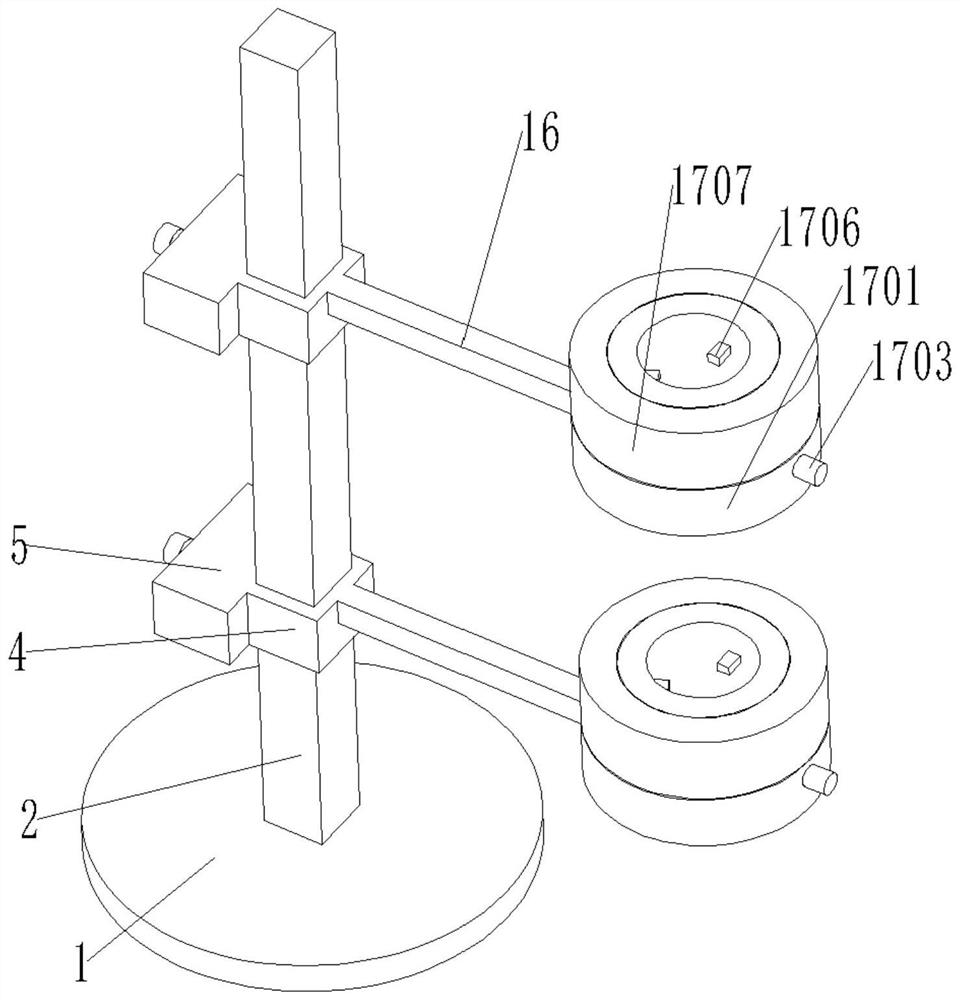

[0025] see figure see Figure 1 to Figure 6 , the present invention provides a technical solution: a brazing coaxial positioning device for elongated objects that prevents solder from flowing, including a supporting chassis 1, a vertical rod 2, a fixed body 5, and a coaxial positioning mechanism 17;

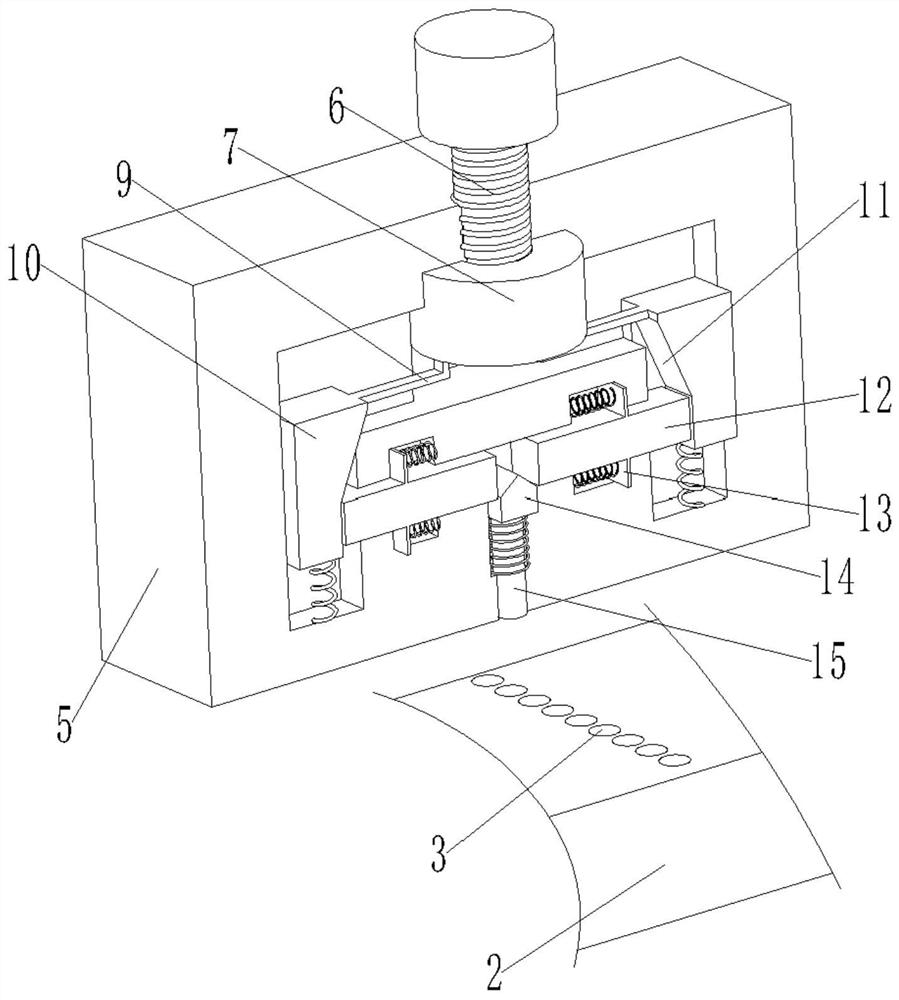

[0026] The support chassis 1 is fixedly connected with a vertical rod 2, and the interior of the vertical rod 2 is equidistantly provided with a positioning circular groove 3, and the vertical rod 2 is slidably connected with a movable frame 4, and the movable frame 4 is fixedly connected with a fixed body 5 ;

[0027] The inside of the fixed body 5 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com