Ultraviolet curing fingernail pigment and preparation method thereof

A technology of ultraviolet rays and nails, applied in the field of pigment production, can solve the problems of many preparation procedures, difficult maintenance, air pollution by pigment atomization, etc., and achieve the effect of simple preparation procedures, small space occupation, and no noise in painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

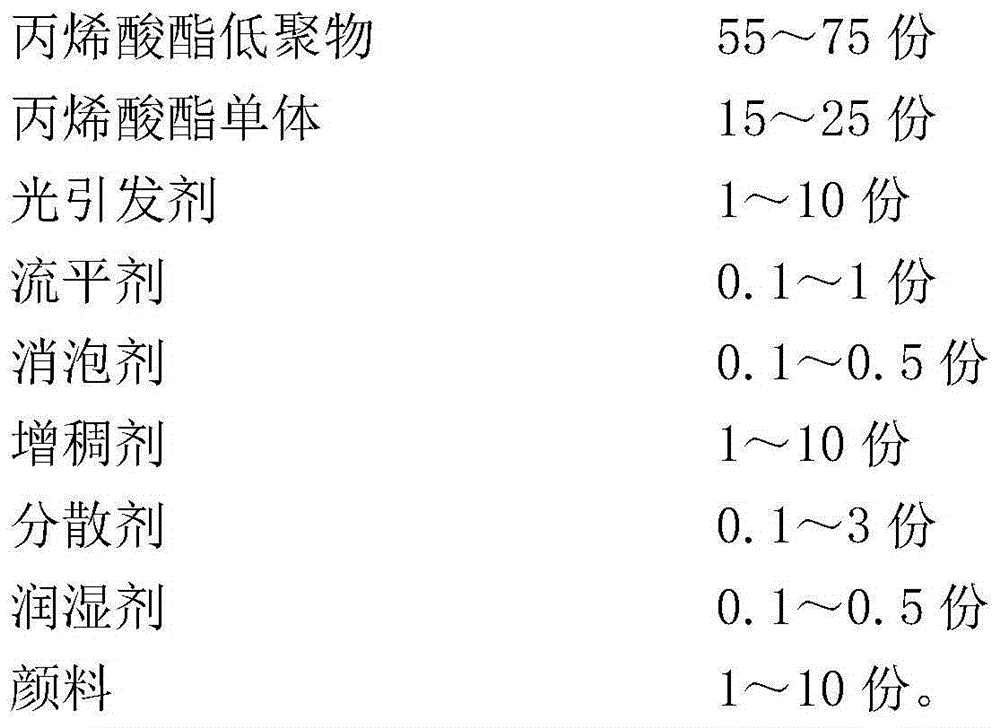

[0027] According to parts by weight, stir 1-10 parts of photoinitiator and 15-25 parts of acrylate monomer at a speed of 1000-2000r / min for 15-20min, dissolve and mix evenly; under stirring condition, add 55-75 1 part of acrylate oligomer, 0.1~3 parts of dispersant, and then stir at 1000~2000r / min for 20~25min to mix evenly; continue to add 0.1~0.5 part of wetting agent, 0.1~1 part of leveling agent, and stir for 20~ Mix evenly for 25 minutes; further add 1-10 parts of pigment, 1-10 parts of thickener, 0.1-0.5 parts of defoamer, stir and mix, grind the resulting mixture until the particle size is less than 20 microns, and filter to obtain UV-curable nail pigment.

Embodiment 2

[0029] In parts by weight, 4.5 parts of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 2 parts of 1-hydroxycyclohexyl phenyl ketone, 15 parts of difunctional acrylate, 3 parts of tetrafunctional Stir methacrylate at a speed of 1500r / min for 18min, dissolve and mix evenly; under stirring conditions, add 65.2 parts of urethane acrylate and 0.5 part of Disperbyk-168 to the above mixed solution, and then stir at a speed of 1500r / min for 25min to mix evenly; Continue to add 0.3 parts of WET270, 0.2 parts containing molecular structure R(OC 3 h 5 ) b (OC 2 h 4 ) a Oh 5 C 3 (Me 2 SiO) n SiMe-leveling agent, stir for 20 minutes to mix evenly; further add 3 parts of red pigment, 5 parts of bentonite, 0.3 parts containing molecular structure -O(SiMe 2 O) X SiMe 2- the antifoaming agent is stirred and mixed, the resulting mixture is ground to a particle size of less than 20 microns, and filtered to obtain an ultraviolet curable nail pigment.

Embodiment 3

[0031] In parts by weight, stir 5 parts of bis-2,6-difluoro-3-pyrrolephenyl titanocene and 15 parts of tetrafunctional acrylate at a speed of 2000r / min for 15min, dissolve and mix evenly; Add 60 parts of polyester acrylate and 0.5 parts of Disperbyk-108 into the liquid, and then stir at 2000r / min for 20 minutes to mix evenly; continue to add 0.5 parts of BYK-168, 0.2 parts containing molecular structure R(OC 3 h 5 ) b (OC 2 h 4 ) a Oh 5 C 3 (Me 2 SiO) n SiMe-leveling agent, stir for 20 minutes to mix evenly; further add 5 parts into black pigment, 6 parts of fumed silica, 0.3 parts containing molecular structure-O(SiMe 2 O) X SiMe 2 - the antifoaming agent is stirred and mixed, the resulting mixture is ground to a particle size of less than 20 microns, and filtered to obtain an ultraviolet curable nail pigment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com