Preparation method of molecular sieve coating slurry for integral catalyst

A molecular sieve and coating slurry technology, applied in chemical instruments and methods, molecular sieve catalysts, physical/chemical process catalysts, etc., can solve the problems of easy plugging, fast sedimentation of molecular sieve catalyst slurry, unstable viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of a stable molecular sieve coating slurry, comprising the following steps:

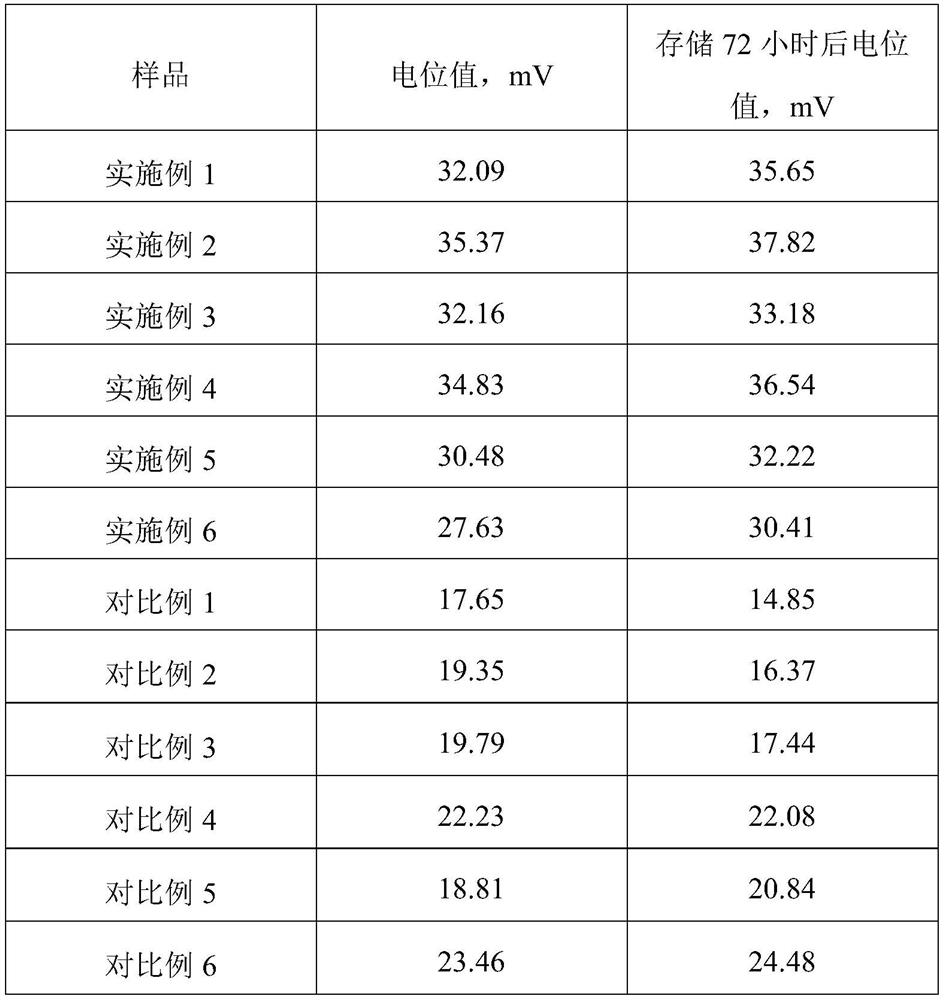

[0030] Adjust the pH of 174g of deionized water to 3.5, add the water into the planetary mill, then add a mixture of 34.8g of aluminum sol dry powder and 126g of Cu-type SSZ-13 (D90 is 8μm) molecular sieve, add 630g of zirconium balls, stir well and use planetary Grind and disperse for 15 minutes at a speed of 300 rpm. After discharge, the slurry was left to age for 2 hours to form a stable slurry, which was characterized by Zeta point. The results are shown in Table 1.

[0031] The Zeta potential value of the coating slurry obtained by this method is 32.09mV, that is, it has reached a stable state. The higher the Zeta potential value, the more stable the dispersion system is. Usually, for slurry, when the potential value reaches 30mV, it can be considered to have reached a stable state.

Embodiment 2

[0033] A preparation method of a stable molecular sieve coating slurry, comprising the following steps:

[0034]Adjust the pH to 3.5 with 174g of deionized water, add the water into the planetary mill, then add 34.8g of aluminum sol dry powder and 126g of Cu-type SSZ-13 (D90 is 5μm) molecular sieve mixture, add 630g of zirconium balls, stir well and use planetary mill Disperse for 15 minutes at a speed of 300 rpm. After discharge, the slurry was left to age for 1 hour to form a stable slurry, which was characterized by Zeta point, and the results are shown in Table 1.

Embodiment 3

[0036] A preparation method of a stable molecular sieve coating slurry, comprising the following steps:

[0037] Adjust the pH of 174g of ionized water to 3.5, add the water into the planetary mill, then add 34.8g of aluminum sol dry powder and 126g of Cu type SSZ-39 (D90 is 8μm) molecular sieve mixture, add 630g of zirconium balls, stir well and disperse with planetary mill 15min, the rotation speed is 300rpm. After discharge, the slurry was left to age for 1 hour to form a stable slurry, which was characterized by Zeta point, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Potential value | aaaaa | aaaaa |

| Potential value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com