Woodworking saw blade sawtooth machining equipment

A technology for processing equipment and woodworking saw blades, which is applied in the direction of metal processing equipment, metal sawing equipment, manufacturing tools, etc., can solve the problems of labor-intensive and time-consuming, staff threats, and easily injured hands, etc., to increase speed and safety , the effect of saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

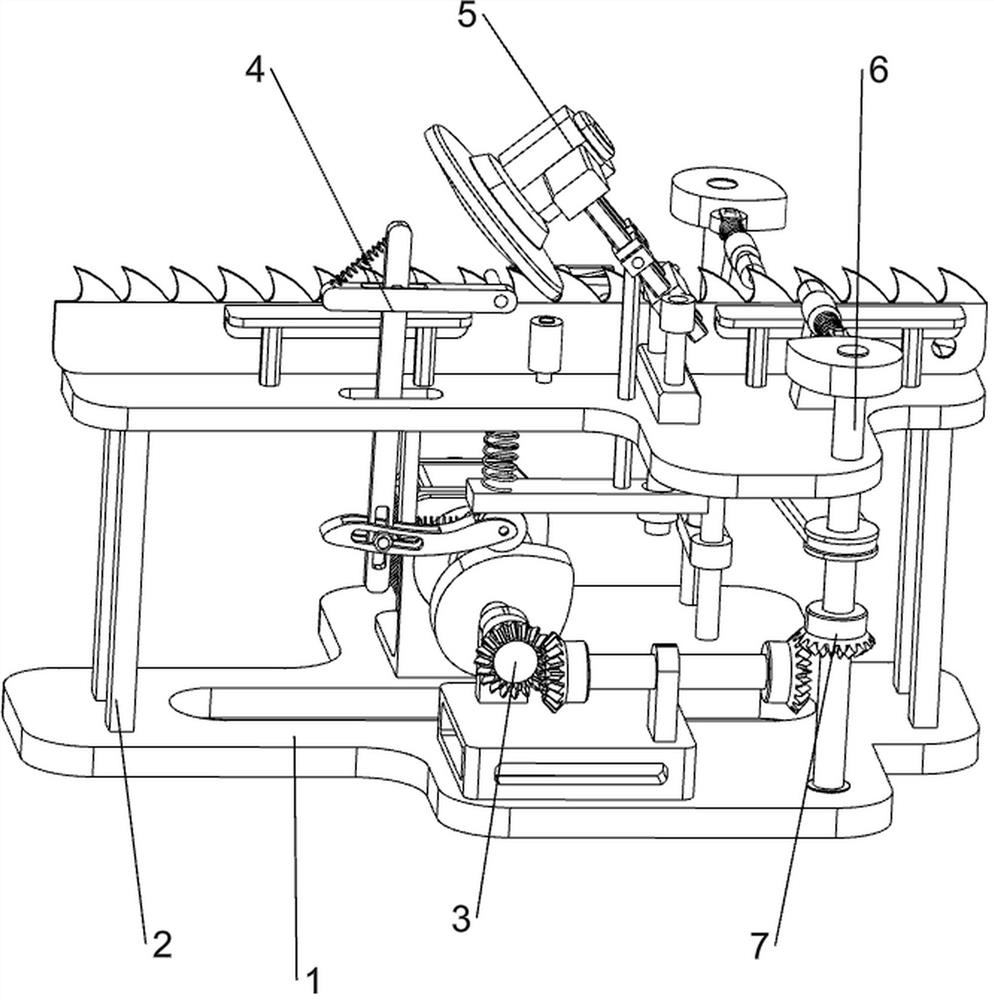

[0026] like figure 1 As shown, a woodworking saw blade sawtooth processing equipment includes a bottom plate 1, a workbench 2, a transmission mechanism 3, a pushing mechanism 4 and a grinding mechanism 5, a workbench 2 is arranged on the top of the bottom plate 1, and a transmission mechanism is arranged in the middle of the top of the bottom plate 1 3. The transmission mechanism 3 is located under the workbench 2. The top left side of the workbench 2 is provided with a pushing mechanism 4, and the top right side of the workbench 2 is provided with a grinding mechanism 5.

[0027] When it is necessary to process the saw blade, the staff first places the saw blade on the workbench 2 at the middle position of the pushing mechanism 4, and then starts the transmission mechanism 3 and the grinding mechanism 5. When the transmission mechanism 3 squeezes the pushing mechanism 4, Pushing mechanism 4 pushes grinding mechanism 5 upwards, and grinding mechanism 5 is lifted upwards, and c...

Embodiment 2

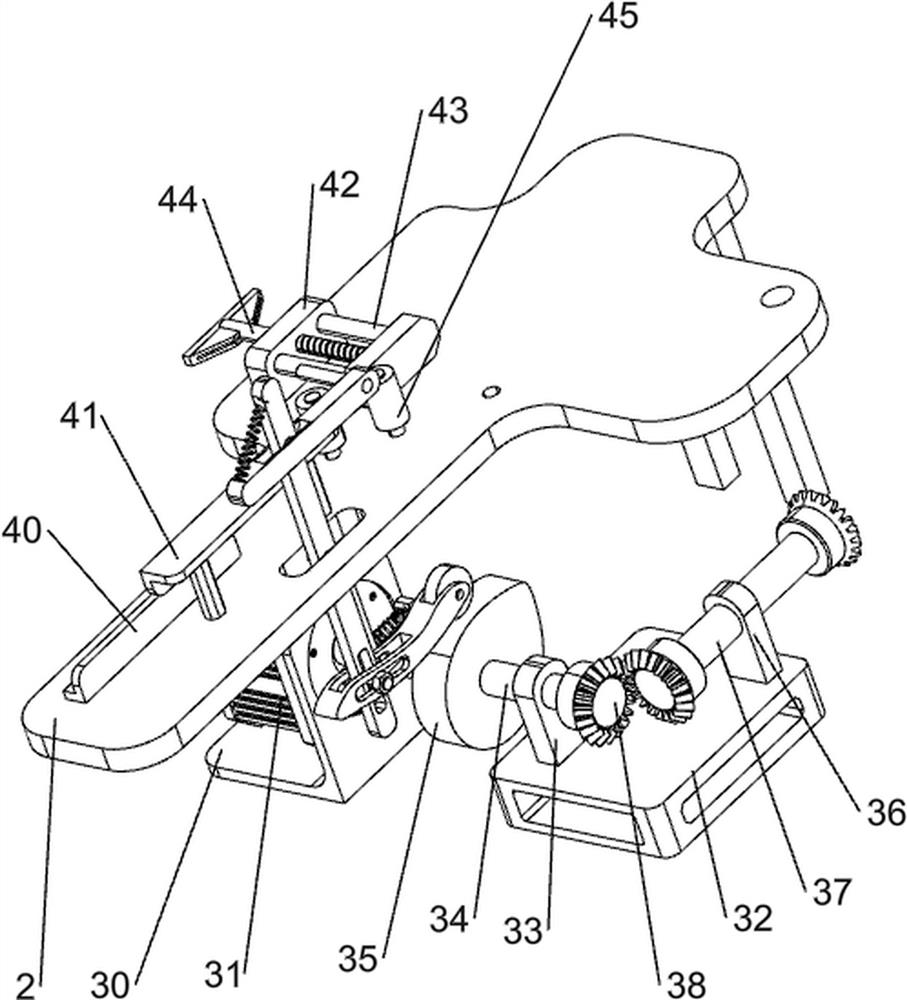

[0029] like figure 2 , image 3 and Figure 4As shown, a woodworking saw blade sawtooth processing equipment, on the basis of Embodiment 1, the transmission mechanism 3 includes a motor bracket 30, a transmission motor 31, a fixed support seat 32, a first bearing seat 33, a first transmission shaft 34, The first cam 35, the second bearing seat 36, the second transmission shaft 37 and the first bevel gear assembly 38, the rear side in the middle of the top of the bottom plate 1 is provided with a motor support 30, and the transmission motor 31 is installed on the motor support 30, and the middle of the top of the bottom plate 1 The front side is provided with a fixed support seat 32, and the rear side of the top of the fixed support seat 32 is provided with a first bearing seat 33. The first bearing seat 33 is provided with a first transmission shaft 34, and the output shaft of the transmission motor 31 is connected to the first bearing seat through a coupling A power transm...

Embodiment 3

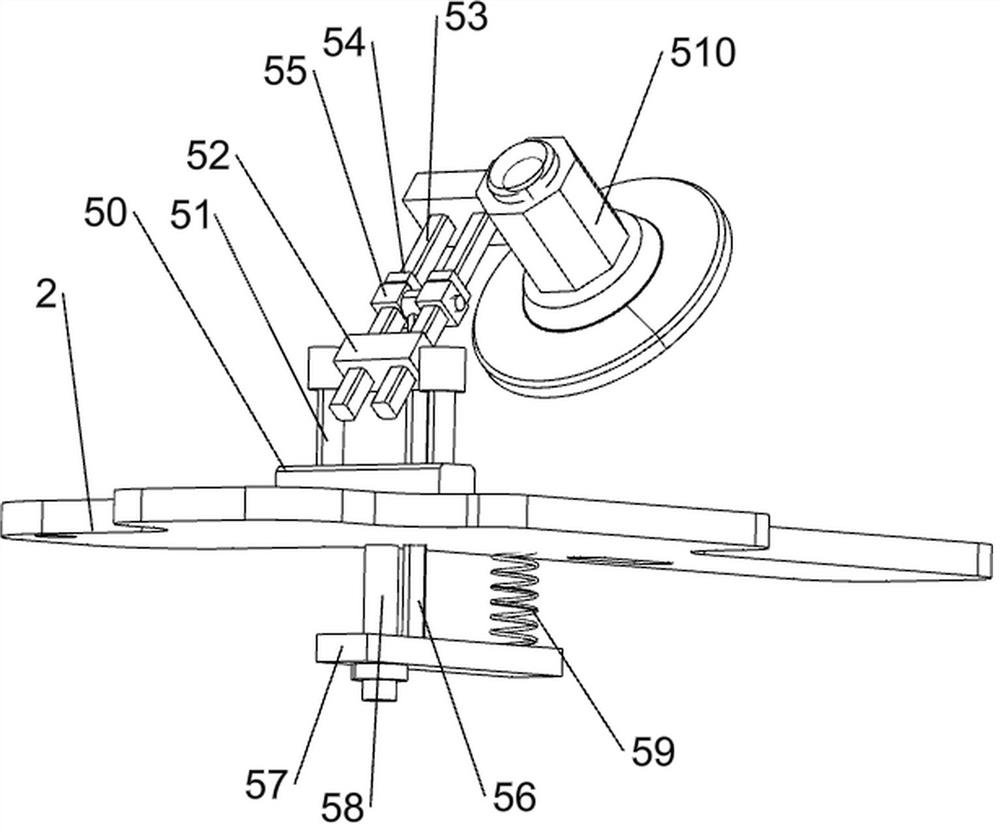

[0036] like Figure 5 As shown, a woodworking saw blade sawtooth processing equipment, on the basis of Embodiment 1 and Embodiment 2, also includes a third transmission shaft 6, a second bevel gear assembly 7, a second cam 8, and a third bearing seat 9 , the second push rod 10, the fourth spring 11, the second roller 12, the support frame 13, the fourth transmission shaft 14, the pulley assembly 15 and the third cam 16, the bottom plate 1 top right front side is provided with the third transmission shaft 6 , the upper end of the third transmission shaft 6 runs through the workbench 2, the second bevel gear assembly 7 is arranged on the right end of the second transmission shaft 37 and the lower end of the third transmission shaft 6, the second cam 8 is arranged on the upper end of the third transmission shaft 6, and the workbench 2. A third bearing seat 9 is arranged on the right side of the top, and a second push rod 10 is provided on the two third bearing seats 9. The opposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com