Supported metalloporphyrin/phthalocyanine catalyst, and preparation method and application thereof

A technology of metalloporphyrin and metallophthalocyanine, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of low binding force of metalloporphyrin/phthalocyanine and low degradation efficiency of organic pollutants , metal porphyrin/phthalocyanine shedding and other problems, to achieve the effect of facilitating degradation, reducing agglomeration, and improving oxidative degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] A method for preparing hemin (FePP, CAS: 16009-13-5) / titanium dioxide composite material based on ball milling, comprising the following steps:

[0071] (1) Weigh 0.05 g of hemin (FePP), 0.5 g of titanium dioxide, add 5 mL of water, put 30 g of zirconia ball milling beads into a zirconia ball mill jar, and mill at a speed of 400 rpm for 2 hours.

[0072] (2) Transfer the milled composite material liquid to a liquid storage tank, clean the zirconia balls and the ball milling tank with distilled water, and transfer the remaining adhered composite catalyst to the liquid storage tank. The ball milling liquid was diluted and quantified to 10g / L.

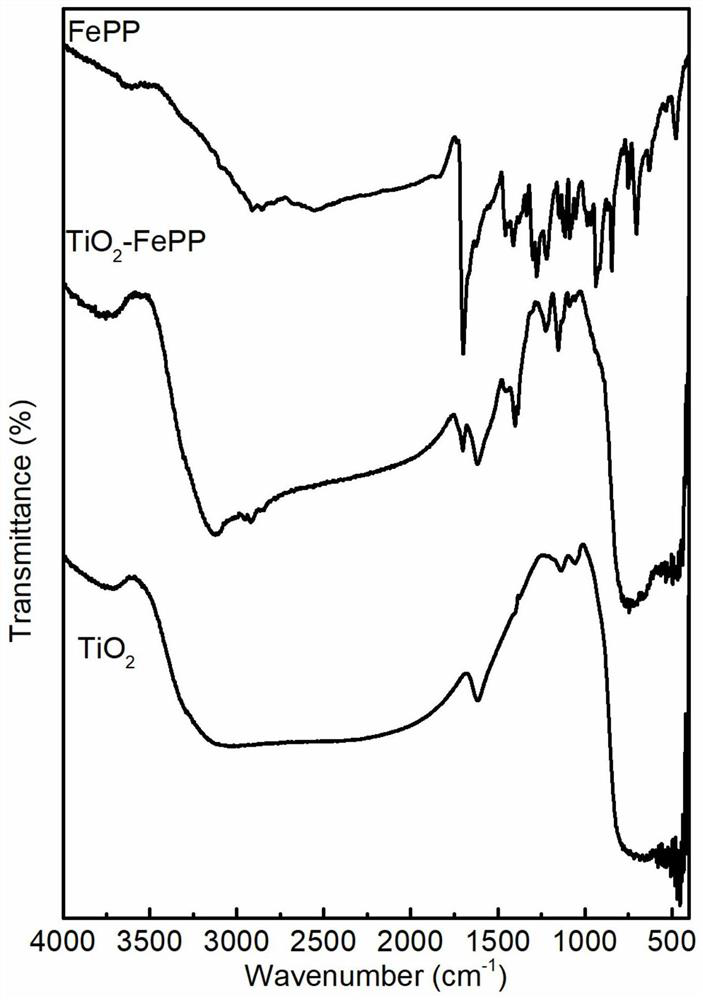

[0073] (3) The ball mill liquid was dried in an oven at 70°C to obtain a composite catalyst powder, and the carrier titanium dioxide and hemin (porphyrin iron) / titanium dioxide were subjected to infrared testing respectively.

[0074] From attached figure 1 It can be seen that the mechanochemical ball milling method can well load...

Embodiment 2

[0076] A method for preparing iron phthalocyanine (FePC, CAS: 132-16-1) / silicon dioxide composite material based on mechanochemical method (ball milling), comprising the following steps:

[0077] (1) Weigh 0.5 g of cobalt phthalocyanine, 2.5 g of silicon dioxide, add 10 mL of water, and put 30 g of zirconia ball milling beads into a zirconia ball mill jar, and mill at a speed of 400 rpm for 2 hours.

[0078] (2) Transfer the milled composite material liquid to a liquid storage tank, clean the zirconia balls and the ball milling tank with distilled water, and transfer the remaining adhered composite catalyst to the liquid storage tank. The ball milling liquid was diluted and quantified to 10g / L.

Embodiment 3

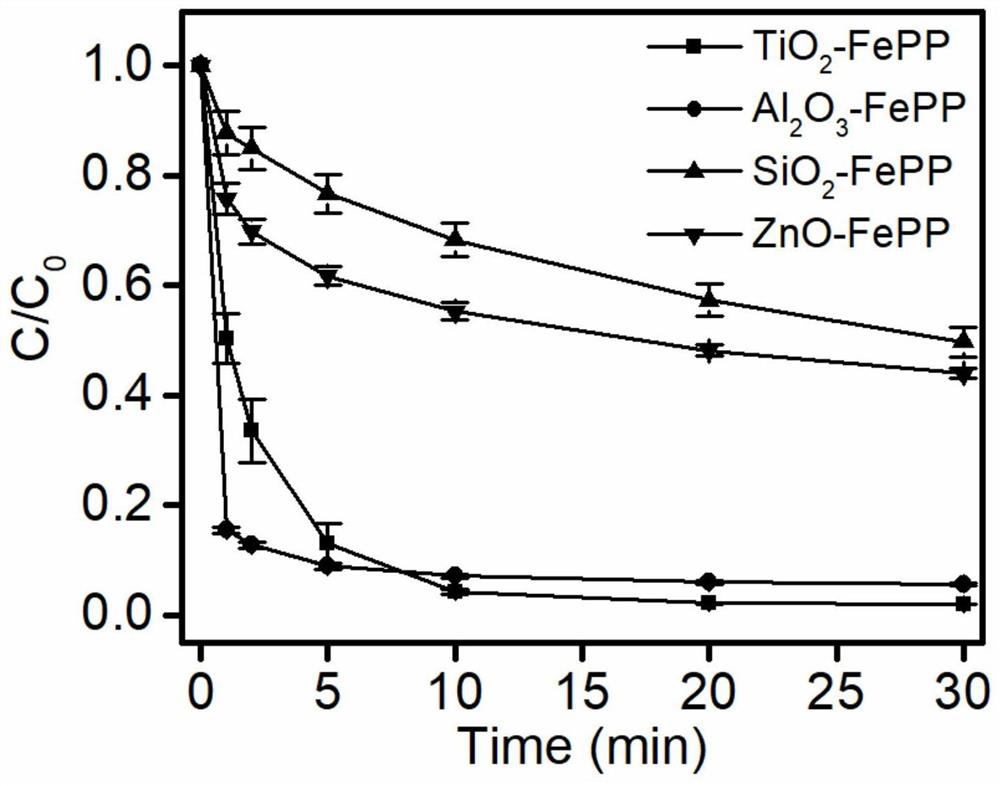

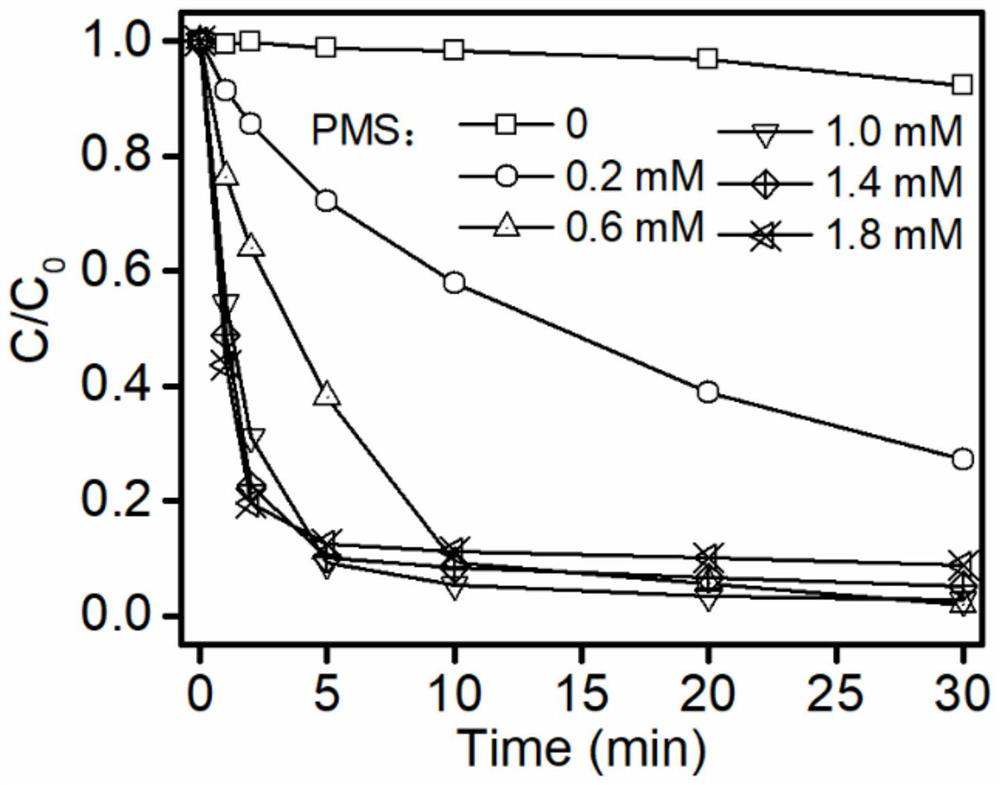

[0080] With the hemin (FePP) / titanium dioxide prepared in Example 1, and according to the preparation method of Example 1, prepared respectively 2 o 3 , SiO 2 , ZnO as the carrier of hemin loading, adding Potassiumhydrogen peroxymonosulfate (PMS) as an activator to carry out the degradation experiment of pollutant trichlorophenol (TCP):

[0081] (1) Potassium monopersulfate (PMS) 50mM: Weigh 3.0738g of potassium monopersulfate (PMS) and dissolve it in 200mL of deionized water to prepare a concentration of 50mM.

[0082] (2) Weigh 0.0987 g of trichlorophenol (TCP) and dissolve it in a 1 L volumetric flask to obtain a stock solution of trichlorophenol (TCP) with a concentration of 500 μM.

[0083] (3) Add 20 mL of trichlorophenol (TCP) stock solution to four 50 mL beakers, add 28.9 mL of deionized water, add 1 mL of PMS stock solution, the concentration of TCP in the system is 200 μM, the pH of the system is 5, and finally add four kinds of 100 μL of catalytic solution (where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com