Microwave heating curing device and process and cured substrate manufactured through process

A curing device and microwave heating technology, which is applied in the field of plant cultivation, can solve the problems of uneven distribution of water in the matrix block, and achieve the effects of easy compression, sufficient heating, and stable appearance structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

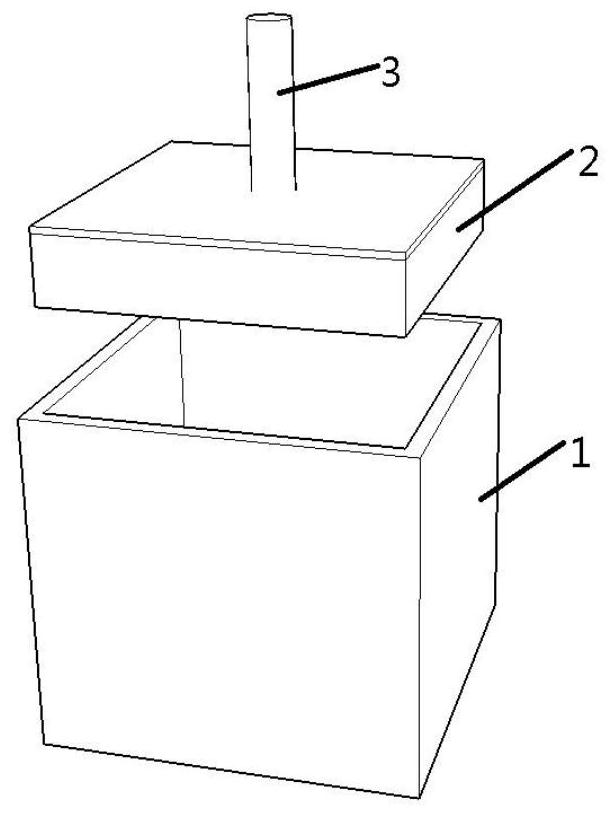

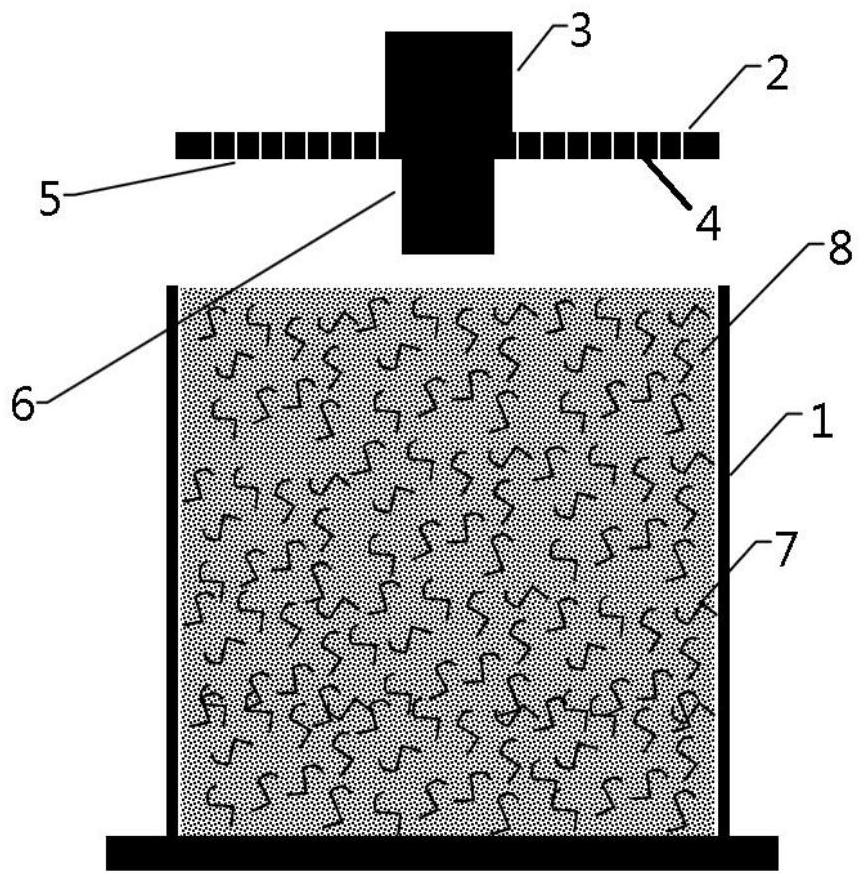

[0035] Such as Figure 1-4 , a microwave heating and curing device, including a mold body 1 and a pressing block 2, the mold body 2 is a square box with an open top, the pressing block 2 is located directly above the mold body 2 and is connected with a pressure mechanism 3 connected, under the action of the pressure mechanism 3, the briquetting block 2 moves vertically in the mold main body 1, and a water seepage system and a microwave generating device 4 are arranged on the briquetting block 2; A planting hole module 6 is arranged in the center of the bottom surface of the block 2, and the shape and size of the planting hole module 6 are consistent with the planting hole. The planting hole module 6 is provided to facilitate the root system of the seedlings transplanted into the solidified matrix block.

[0036] In this embodiment, the water seepage system includes a plurality of water seepage ports 5 evenly distributed on the compact, and the water seepage ports 5 are connec...

Embodiment 2

[0043] Such as Figure 1-4 , a microwave heating and curing device, including a mold body 1 and a pressing block 2, the mold body 2 is a square box with an open top, the pressing block 2 is located directly above the mold body 2 and is connected with a pressure mechanism 3 connected, under the action of the pressure mechanism 3, the briquetting block 2 moves vertically in the mold main body 1, and a water seepage system and a microwave generating device 4 are arranged on the briquetting block 2; A planting hole module 6 is arranged in the center of the bottom surface of the block 2, and the shape and size of the planting hole module 6 are consistent with the planting hole. The planting hole module 6 is provided to facilitate the root system of the seedlings transplanted into the solidified matrix block.

[0044] In this embodiment, the water seepage system includes a plurality of water seepage ports 5 evenly distributed on the compact, and the water seepage ports 5 are connec...

Embodiment 3

[0051] Such as Figure 1-4 , a microwave heating and curing device, including a mold body 1 and a pressing block 2, the mold body 2 is a square box with an open top, the pressing block 2 is located directly above the mold body 2 and is connected with a pressure mechanism 3 connected, under the action of the pressure mechanism 3, the briquetting block 2 moves vertically in the mold main body 1, and a water seepage system and a microwave generating device 4 are arranged on the briquetting block 2; A planting hole module 6 is arranged in the center of the bottom surface of the block 2, and the shape and size of the planting hole module 6 are consistent with the planting hole. The planting hole module 6 is provided to facilitate the root system of the seedlings transplanted into the solidified matrix block.

[0052] In this embodiment, the water seepage system includes a plurality of water seepage ports 5 evenly distributed on the compact, and the water seepage ports 5 are connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com