Permanent magnet direct drive variable frequency motor all-in-one machine state monitoring system

A state monitoring system, frequency conversion motor technology, applied in control systems, motor control, electromechanical devices, etc., can solve problems such as inability to correctly display the actual state of the equipment, unfavorable drive performance of the inverter, unstable host computer signals, etc., to achieve anti-transmission The effect of strong fluctuation ability of light intensity, flexible probe form and easy development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

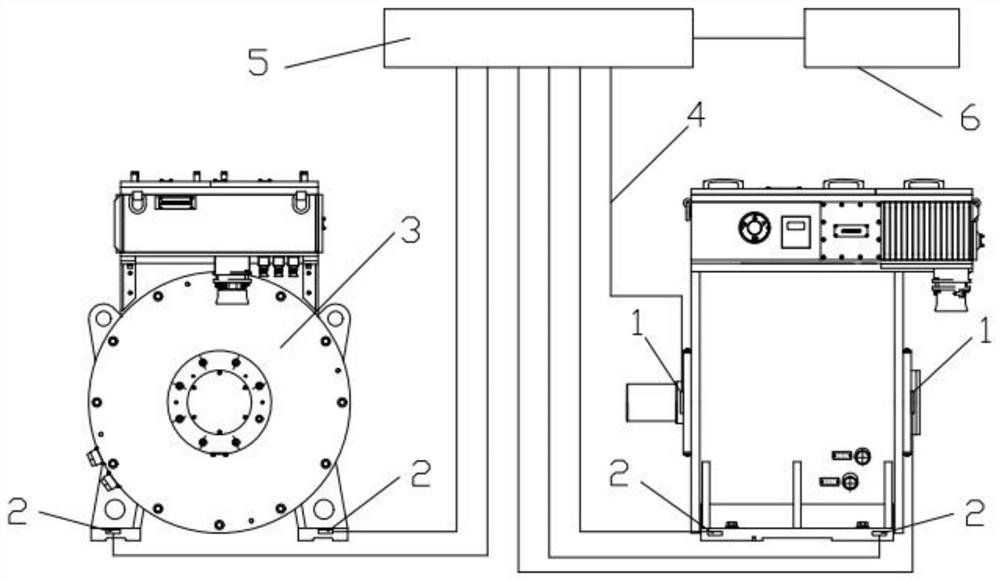

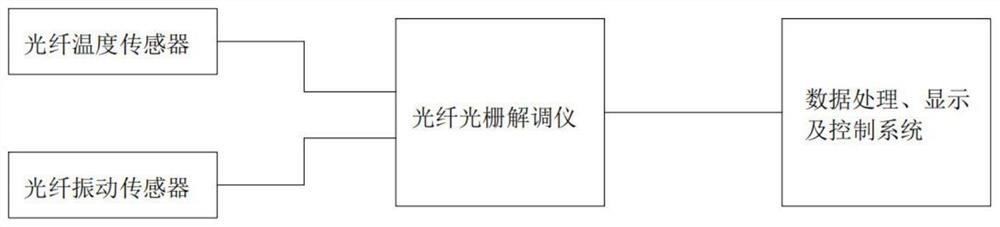

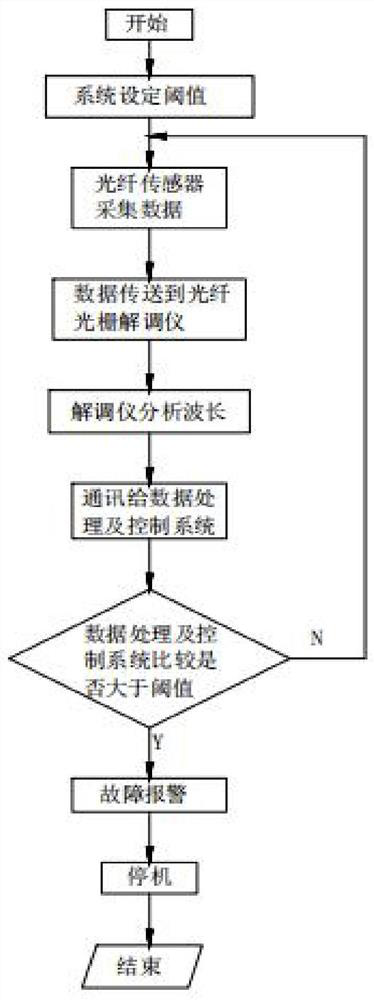

[0025] refer to Figure 1-3 , a permanent magnet direct drive variable frequency motor integrated machine status monitoring system, including an optical fiber temperature sensor 1, an optical fiber vibration sensor 2, a permanent magnet direct drive variable frequency motor integrated machine 3, a fiber grating demodulator 5, a transmission optical fiber 4, and a control system 6 , the optical fiber temperature sensor 1 and the optical fiber vibration sensor 2 are fixedly installed on the outer wall of the permanent magnet direct drive variable frequency motor integrated machine 3, the output ends of the optical fiber temperature sensor 1 and the optical fiber vibration sensor 2 are electrically connected to the input end of the optical fiber grating demodulator 5 connection, the output end of the fiber grating demodulator 5 is electrically connected to the input end of the control system 6, and in operation, the optical signal measured by the optical fiber temperature sensor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com