A device for testing the structural performance of prefabricated concrete components

A prefabricated component and structural performance technology, applied in the direction of measuring devices, machine/structural component testing, strength characteristics, etc., can solve the problem of inconvenient concrete prefabricated component clamping, inability to uniformly disperse load pressure, and affect the strength detection of concrete prefabricated components Accuracy and other issues to achieve the effect of improving stability, improving accuracy, and evenly dispersing load pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

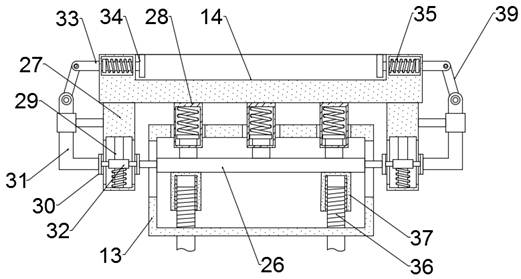

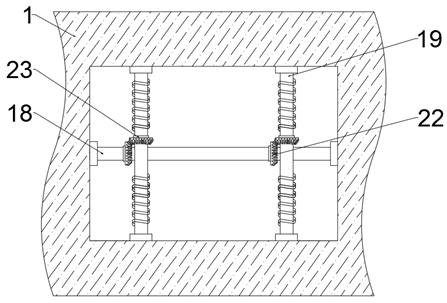

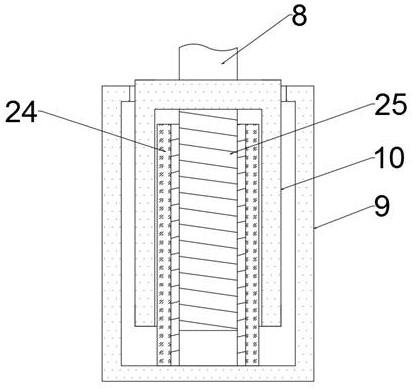

[0024]Example 1: SeeFigure 1-4, A concrete prefabricated component structure performance testing device, including base 1, down push assembly, drive assembly, linkage assembly, transmission mechanism, top rising mechanism, and clamping mechanism, base 1 is a rectangular shape provided, and the base 1 top The middle portion of the side has a support post 2 vertically, and the middle portion of the support column 2 is vertically opened with a linkage chamber, and a linkage assembly is provided in the linkage chamber; the top surface of the support column 2 is secured to the top plate 3, Above the top surface of the top plate 3 is fixed to the mounting plate 4, the top surface of the mounting plate 4 is provided with an electric chassis, and the motor 7 is vertically provided in the motor 7, and the central level activity between the support column 2 is attached. The plate 5, the bottom surface of the lifting plate 5 is fixed to the lower pressure plate, and the bottom surface of the l...

Embodiment 2

[0029]Example 2: In the present embodiment, the present invention also proposes a structural performance inspection apparatus for concrete prefabricated components, including the following steps:

[0030]Step, first, the motor 7 is electrically connected to the external power source, and then placed in the placed cell, then the gravity of the concrete prefabricated member itself is lowered downward, by placing The decline in the stage 14 facilitates the pressing connection post 28 for tall, and it is convenient to reduce the spacing between the fixing seat 13 and the placement table 14 to facilitate the push rod 31 to push the hinge 39. The rod 33 is transformed toward the direction of the placed slot, facilitating the push pin 34 to the concrete prefabricated member by the transverse shift of the crossbar 33, facilitating the scope of the sharing the concrete prefabricated member in the plain cell;

[0031]Step 2, when the concrete prefabricating member is required to perform strength de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com